Optimal Cold Meat Storage Practices for Refrigeration in Food Processing Facilities

Cold Meat Storage for Fridge Factories

Cold meat storage is an essential component of the food production and distribution chain, particularly for fridge factories that handle large quantities of meat products. The proper storage of cold meats ensures quality, safety, and longevity, making it a critical factor for both manufacturers and consumers. In this article, we will explore the importance of effective cold meat storage practices, the technologies involved, and the implications of improper storage.

Importance of Cold Meat Storage

The primary goal of cold meat storage is to maintain the freshness and safety of meat products. Meat is highly perishable due to its protein-rich composition, which makes it a target for microbial growth. Bacteria, yeast, and molds can proliferate rapidly if meat is not stored at the right temperature. This can lead to spoilage, loss of taste and texture, and foodborne illnesses, posing significant health risks to consumers.

Moreover, appropriate storage conditions help to preserve the nutritional value of the meat. Vitamins and other beneficial compounds can degrade if the meat is exposed to improper temperatures or prolonged storage times. Therefore, maintaining a stable, cold environment is crucial for enhancing the shelf life of meat products and ensuring that they meet safety regulations.

Ideal Storage Conditions

Fridge factories utilize specialized refrigeration systems to create optimal storage environments for cold meats. The General guideline for meat storage is to keep the temperature at or below 4°C (39°F) to slow down bacterial activity. In some cases, meats are stored at even lower temperatures, especially for long-term storage or transportation, where freezing at -18°C (0°F) is common.

Humidity levels also play a vital role in meat storage. A relative humidity of 85-90% is ideal to prevent dehydration and maintain the quality of the meat. These conditions help to keep the meat moist and flavorful while preventing excessive weight loss due to evaporation. However, it is equally important to manage humidity to avoid excessive moisture, which can encourage the growth of bacteria and mold.

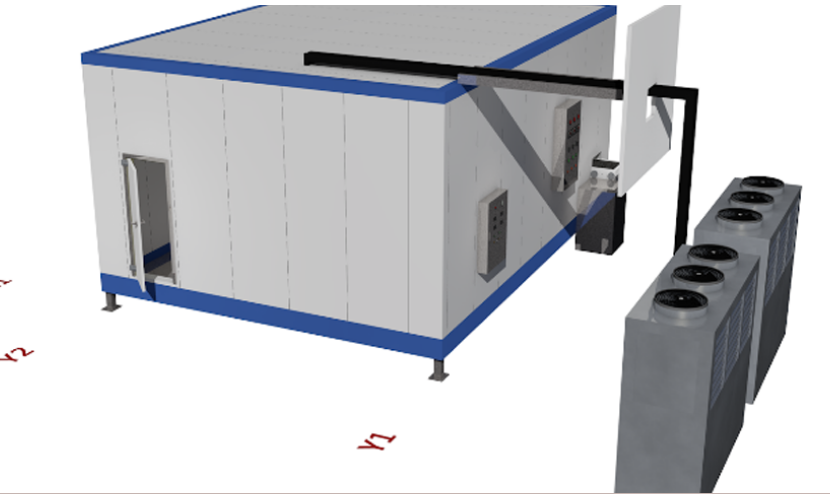

cold meat storage for fridge factories

Technologies in Cold Meat Storage

With advancements in technology, modern fridge factories rely on advanced refrigeration systems equipped with sensors and automation to ensure precise temperature and humidity control. Smart monitoring systems help factory operators maintain optimal storage conditions in real-time, alerting them to any fluctuations that could jeopardize the quality of the meat.

Additionally, vacuum sealing and modified atmosphere packaging (MAP) have emerged as effective methods to extend the shelf life of cold meats. By removing oxygen and replacing it with gases that inhibit bacterial growth, these techniques help to preserve color, flavor, and texture while reducing spoilage rates.

Consequences of Improper Storage

Failing to adhere to proper cold meat storage practices can lead to dire consequences. Expired or spoiled meat can cause food poisoning outbreaks, resulting in serious health risks and legal repercussions for suppliers or factories. Not only does this harm consumers, but it can also severely tarnish the reputation of a brand.

Moreover, economic losses due to spoiled inventory can be substantial. Businesses may face increased operational costs related to waste disposal, product recalls, and potential lawsuits. For this reason, investing in robust cold storage solutions is not just about compliance; it is also a sound business strategy.

Conclusion

In conclusion, cold meat storage is a critical aspect of the meat production and processing industry, particularly for fridge factories. Ensuring that meat products are stored under optimal conditions is vital for maintaining their quality, safety, and longevity. With the right technologies and best practices in place, businesses can safeguard their products and provide consumers with safe, high-quality meat. By prioritizing effective cold meat storage, companies can not only comply with health regulations but also enhance their overall operational efficiency and brand reputation. As the industry continues to evolve, so too must the methods of storage that protect this essential food group.