Hermetic Condensing Unit Manufacturing Process and Best Practices for Efficiency

The Hermetic Condensing Unit Factory Engineering Excellence in Refrigeration

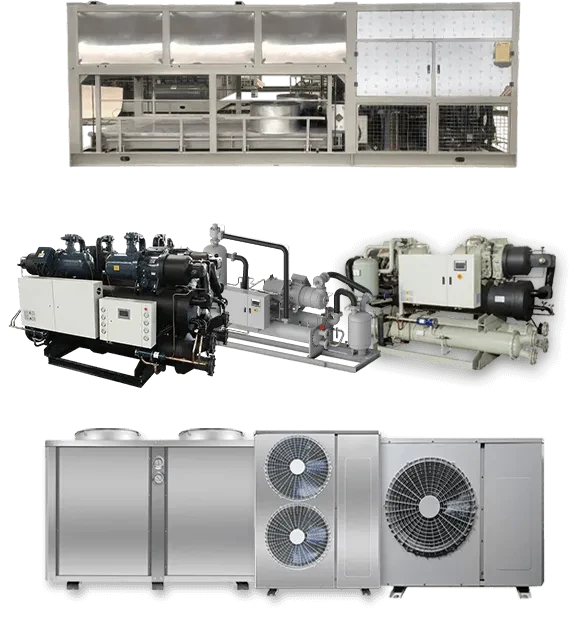

In the realm of modern refrigeration technology, the hermetic condensing unit stands as a cornerstone for various applications, ranging from residential to industrial cooling systems. This essential piece of equipment efficiently compresses refrigerants and ensures optimal heat exchange, ultimately resulting in a seamless cooling process. At the heart of this innovation lies the hermetic condensing unit factory, where engineering prowess, technological advancements, and meticulous craftsmanship converge to produce high-quality units that meet global standards.

Understanding Hermetic Condensing Units

Before delving into the factory's operations, it is vital to understand what hermetic condensing units are. These units are characterized by their closed-system design, where the compressor and condenser are contained within a sealed housing. This hermetic sealing prevents refrigerant leakage, enhances efficiency, and minimizes maintenance requirements. The result is a refrigeration system that operates smoothly, with lower energy consumption compared to traditional units.

The core components of a hermetic condensing unit include the compressor, condenser, expansion valve, and evaporator. Each component plays a crucial role in the refrigeration cycle, ensuring the effective transfer of heat and the maintenance of desired temperature levels. The integrated nature of these units simplifies installation, making them a preferred choice for commercial and residential applications alike.

The Design and Manufacturing Process

The operation of a hermetic condensing unit factory is a marvel of modern manufacturing. From the initial design phase to final production, each step is characterized by precision and attention to detail. Engineers utilize advanced computer-aided design (CAD) software to create blueprints that optimize the unit’s performance, energy efficiency, and durability. This phase is critical, as it ensures that the final product meets both industry standards and customer specifications.

Once the design is finalized, the manufacturing process begins. The factory employs state-of-the-art machinery and technology to fabricate components such as compressors and condensers. These components are often made from high-quality materials like metals and alloys that can withstand the rigors of refrigeration while maintaining efficiency. The use of automated processes ensures consistent quality and reduces human error in production.

hermetic condensing unit factory

After fabrication, the assembly line takes over. Skilled technicians carefully assemble each unit, ensuring that every component is correctly positioned and securely fastened. Quality control is paramount during this stage, with rigorous testing protocols in place to assess each unit's performance, safety, and reliability. These tests often include pressure tests, leak tests, and function tests to ensure the unit operates as intended.

Sustainability and Innovation

As environmental concerns continue to shape industries worldwide, hermetic condensing unit factories are increasingly adopting sustainable practices. This includes the use of eco-friendly refrigerants, which have lower global warming potential compared to traditional refrigerants. Additionally, factories are working towards reducing energy consumption in their manufacturing processes, implementing energy-efficient machinery, and recycling waste materials wherever possible.

Moreover, innovation is a driving force in the industry. Research and development teams are continuously exploring ways to enhance the efficiency and performance of hermetic condensing units. This includes advancements in compressor technology, improving heat exchange processes, and integrating smart technology that allows for real-time monitoring and adjustment of operating conditions. These innovations not only contribute to energy savings but also enhance user experience through easier maintenance and greater control over temperature settings.

The Future of Hermetic Condensing Units

Looking ahead, the future of hermetic condensing unit factories appears bright. As global demand for refrigeration systems continues to rise, especially in emerging markets, these factories are well-positioned to meet the challenge. The ongoing evolution of technology and materials science promises to unlock new possibilities for unit design and functionality, driving the sector towards even greater efficiency and sustainability.

In conclusion, the hermetic condensing unit factory embodies a combination of tradition and innovation. By leveraging cutting-edge technology, sustainable practices, and expert craftsmanship, these factories produce vital components that fuel the refrigeration industry. As we move forward, their role will only become more significant in ensuring that our cooling needs are met efficiently and responsibly, ensuring a comfortable and sustainable future for all.

-

The Role of Modern Ice Machines in Food, Beverage, and Industrial ApplicationsNewsAug.24,2025

-

Next-Generation IQF Solutions: From Small IQF Freezer to Emergency Cold Storage TechnologiesNewsAug.24,2025

-

Advanced Refrigeration Technology: From Airtight Freezer Machine to Intelligent Cold Storage SolutionsNewsAug.24,2025

-

Reliable Cold Storage Rooms for Sale and Modern Industrial Refrigeration SolutionsNewsAug.24,2025

-

Reliable Coolroom for Sale and Advanced Cold Storage SolutionsNewsAug.24,2025

-

Cold Room Cost And Refrigeration Solutions From Shijiazhuang XuexiangNewsAug.24,2025