Commercial Tube Ice Machine For Sale | Efficient Ice Making

Understanding Tube Ice Technology and Current Industry Trends

The global industrial and commercial sectors are witnessing an escalating demand for highly efficient and unequivocally reliable ice production solutions, driving continuous innovation within the refrigeration domain. Prominently positioned at the forefront of these technological advancements, the Tube Ice Machine has emerged as an exceptionally sought-after solution, particularly for businesses keen on acquiring a tube ice machine for sale. These sophisticated machines are meticulously engineered to produce distinctive cylindrical, hollow ice tubes, typically ranging in diameter from 20mm to 35mm and in length from 25mm to 50mm. This unique form factor makes them exceptionally versatile for a myriad of applications, primarily owing to their large contact surface area, which facilitates rapid cooling, and their robust structure, which ensures a remarkably slow melting rate compared to other ice types. Current industry trends clearly indicate a robust growth trajectory for this technology, significantly propelled by escalating requirements across critical sectors such including large-scale food processing, precise chemical cooling, comprehensive concrete cooling in construction, and rigorous fishery operations. The market is increasingly pivoting towards systems that offer superior energy efficiency, adherence to stringent environmental regulations, and high levels of automation that minimize the need for manual intervention while maximizing operational stability. A paramount focus is also placed on ensuring impeccable hygiene and unwavering compliance with international food safety standards, compelling leading manufacturers to integrate advanced, food-grade materials and sophisticated, automated cleaning mechanisms into their designs. Furthermore, substantial investment in research and development is concentrated on optimizing heat exchange efficiency, substantially reducing overall power consumption (measured in kWh/ton of ice), and significantly enhancing the lifespan of critical components. This ensures that modern tube ice machine for sale units deliver unparalleled performance and superior cost-effectiveness throughout their extended operational duration. This continuous technological evolution critically underscores the strategic imperative of selecting a machine that not only robustly satisfies immediate operational demands but also meticulously aligns with future industrial requirements, thereby guaranteeing a formidable return on investment and contributing to the sustainable growth of businesses seeking advanced cooling solutions.

The Manufacturing Excellence of a Tube Ice Machine

Materials and Fabrication Process

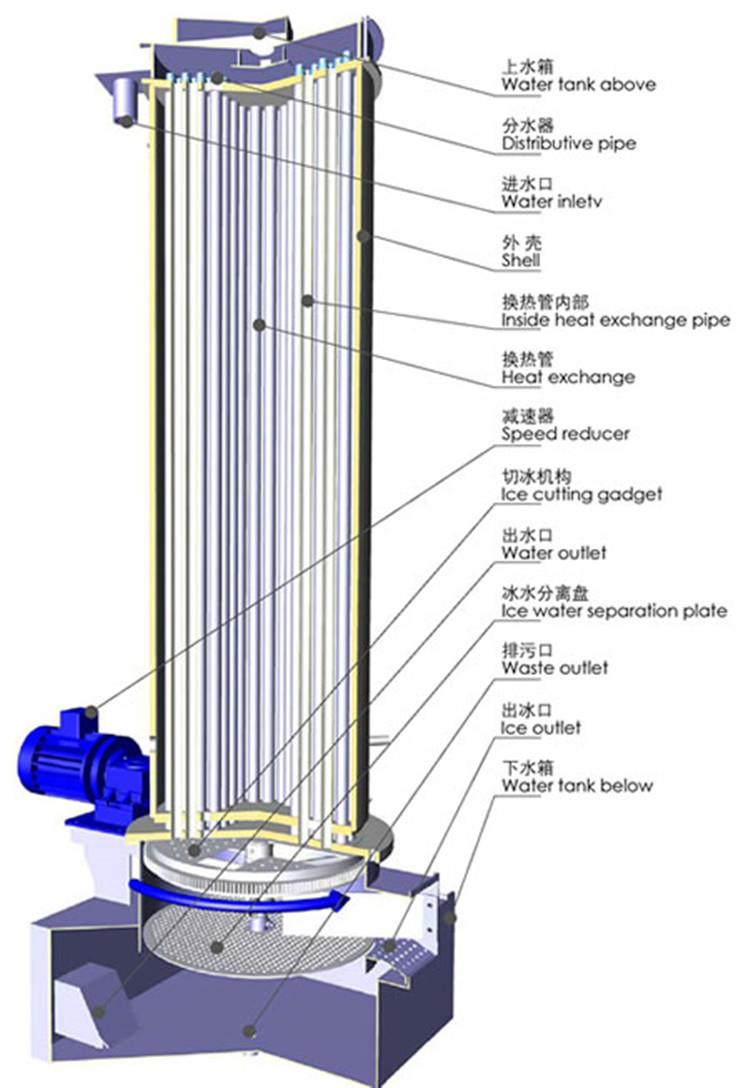

The exceptional structural integrity and reliable operational performance characteristic of a top-tier tube ice making machine are direct outcomes of an extraordinarily meticulous manufacturing process coupled with the judicious selection of high-grade, robust materials. Fundamentally, the most critical components—such as the evaporator barrel (which serves as the ice generator), the primary water tank, and the intricate network of refrigeration pipelines—are exclusively constructed from premium, food-grade Stainless Steel 304 or, for more demanding applications, Stainless Steel 316. This material choice is paramount as it ensures not only superb corrosion resistance, which is vital in humid and often chemically active environments, but also uncompromised hygiene, a non-negotiable requirement for any tube ice machine for sale intended for applications demanding purity, particularly in the food and pharmaceutical sectors. The fabrication process itself employs advanced manufacturing techniques, including precision CNC (Computer Numerical Control) machining for the meticulous shaping of components, guaranteeing incredibly exact tolerances and optimal, seamless fit. Welding, a critical joining process, is expertly performed using either TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) methods, yielding exceptionally strong, clean, and durable joints that are free from contaminants and structural weaknesses. For the machine's primary structural supports and frameworks, high-strength industrial steel is utilized, rigorously treated with protective coatings to effectively resist environmental wear, rust, and fatigue. The core operational principle involves the precise circulation of a refrigerant, such as R404A, within the internal tubes of the evaporator, which are themselves submerged within a continuously recirculating water bath. As the water progressively freezes onto the inner surfaces of these tubes, forming uniform ice tubes, a swift hot gas defrost cycle is subsequently initiated to release the formed ice, which then gravitationally descends onto a precisely rotating ice cutter. This intricate and highly synchronized process inherently demands an unparalleled level of material integrity, precision engineering, and robust component integration to ensure consistent and efficient ice production over extended periods.

Quality Assurance and Standards

Unwavering adherence to stringent international quality and safety standards is an absolute imperative in the production of any reliable tube ice machine for sale. Leading manufacturers typically operate under, and are certified to, ISO 9001 for their comprehensive quality management systems. This certification provides an authoritative assurance of consistent product quality, from the initial conceptual design phase through to material procurement, manufacturing, assembly, and final delivery. Furthermore, for components that come into direct contact with food or beverage products, compliance with FDA (Food and Drug Administration) standards is strictly maintained, unequivocally guaranteeing the material safety and non-toxicity of ice produced. Pressure vessels and complex refrigeration systems, which form the core of the ice machine, are engineered and manufactured to conform to rigorous global standards such as CE (Conformité Européenne) marking for market access within Europe, or ASME (American Society of Mechanical Engineers) Boiler and Pressure Vessel Code standards in North America, ensuring the highest level of safety and operational integrity. Prior to dispatch, every single machine undergoes a battery of exhaustive tests, including high-pressure tests for all refrigerant circuits to detect any leaks, comprehensive performance tests conducted under varying load conditions and ambient temperatures to verify output capacity, and extended continuous operational runs to confirm long-term stability, efficiency, and consistent ice production. Detailed and systematic quality control checks are meticulously performed at every critical stage of the production lifecycle, ranging from rigorous raw material inspection (including advanced spectral analysis of stainless steel alloys to confirm composition) to precise component assembly and the final functional and aesthetic inspection before packaging. This holistic and multi-layered approach to quality assurance significantly contributes to the extended operational lifespan of the machinery, which can typically range from 10 to 15 years or more with diligent and proper maintenance, thereby establishing it as a highly robust and prudent investment for demanding industries such as large-scale food processing, specialized chemical manufacturing, comprehensive logistics, and crucial water supply and drainage systems.

Applicable Industries and Advantages

The inherent versatility of tube ice machines makes them highly advantageous across a diverse array of industrial and commercial sectors, each capitalizing on the unique characteristics of tube ice and the robust design of the equipment. In the critical petrochemical industry, these machines are extensively utilized for process cooling, where they are instrumental in maintaining stable, precise temperatures for exothermic reactions, or for the efficient chilling of specific product streams to prevent degradation or facilitate separation. The metallurgical sector significantly employs tube ice for the rapid quenching of heated materials, a process crucial for achieving desired material properties, or for effectively cooling large-scale industrial equipment, benefiting immensely from tube ice’s uniform and efficient cooling effect. For the essential water supply and drainage industry, tube ice finds application in various water treatment processes, such as chilling water for specific chemical reactions, or for the temporary bulk cold storage of treated water. A pivotal advantage of these machines, especially when considering a commercial tube ice machine, is their exceptional energy efficiency. Modern designs integrate state-of-the-art, high-efficiency compressors (such as semi-hermetic screw compressors for larger capacities), meticulously optimized heat exchangers with enhanced surface areas, and intelligent, programmable logic controller (PLC)-based control systems. These advanced features collectively work to minimize power consumption per ton of ice produced. For example, some cutting-edge models achieve a Coefficient of Performance (COP) values exceeding 4.0, or specific energy consumption as low as 60-70 kWh/ton, leading to substantial reductions in operational costs over the machine’s lifecycle. Furthermore, the strategic selection of highly corrosion-resistant materials, predominantly 304 or 316 stainless steel, for all surfaces that come into contact with water or ice, guarantees an extended lifespan and significantly minimizes maintenance requirements, particularly in harsh or corrosive industrial environments. This premium material choice provides superior protection against rust, chemical degradation, and bacterial buildup compared to conventional systems. When assessing a tube ice machine for sale for long-term industrial use, the integration of cutting-edge technologies that minimize energy consumption and enhance durability stands as a paramount consideration, ensuring consistent, reliable performance and a robust return on investment in demanding operational settings globally.

Technical Specifications and Performance Metrics

When meticulously evaluating a tube ice machine for sale, a comprehensive understanding of its technical specifications and performance metrics is absolutely pivotal for making an informed, strategic procurement decision that aligns with operational needs and long-term financial objectives. The most critical parameter is the daily ice production capacity, which can span an immense range from compact units producing merely 1 ton to colossal industrial systems capable of generating over 100 tons per 24 hours, directly determined by the scale and number of integrated evaporator units. The choice of refrigerant type, most commonly R404A (a hydrofluorocarbon blend preferred for its lower ozone depletion potential) or historically R22 (a hydrochlorofluorocarbon currently undergoing phase-out due to environmental concerns), directly impacts both the system's energy efficiency and its compliance with evolving global environmental regulations. Power consumption, a crucial operational cost factor, is meticulously measured in kilowatt-hours per ton of ice produced (kWh/ton), with cutting-edge, highly efficient machines consuming as little as 60-70 kWh/ton under optimal environmental conditions, whereas older or less efficient models might exceed 100 kWh/ton, leading to significantly higher operating expenditures. The physical dimensions and overall weight of the machine are equally important considerations, especially for intricate installation planning within existing facilities that may have limited available space, requiring careful structural assessment. While a tube ice machine typically operates as a closed-loop system with minimal water loss, water consumption, primarily for make-up water to compensate for minor evaporation or system purges, remains a factor that necessitates consideration, particularly in regions facing water scarcity. Crucially, actual output and operational efficiency are significantly influenced by fluctuating operating conditions, such as ambient air temperature and incoming water inlet temperature; thus, reputable manufacturers provide detailed performance curves illustrating system behavior across various environmental scenarios to ensure transparency and accurate planning. Furthermore, noise levels, which typically range from 70-85 dB for industrial machinery, are also highly relevant for compliance with occupational health and safety regulations in specific industrial environments. The table below presents a representative overview of key technical parameters for a selection of standard Tube Ice Machine models, unequivocally showcasing the broad diversity in available capacities and performance characteristics meticulously designed to meet the varying and often highly specialized demands of diverse industrial applications.

| Model Series | Ice Capacity (Tons/24h) | Power Consumption (kWh/Ton) | Refrigerant Type | Condensing Method | Approx. Dimensions (LWH, mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| Tube Ice 5T | 5 | 75-85 | R404A | Air/Water Cooled | 2500x1500x2200 | 1800 |

| Tube Ice 10T | 10 | 70-80 | R404A | Water Cooled | 3500x2000x2800 | 3500 |

| Tube Ice 20T | 20 | 65-75 | R404A | Water Cooled | 4500x2500x3500 | 6000 |

The performance of a tube ice making machine is also profoundly influenced by the diligently selected refrigeration system, which encompasses the specific type and calibrated capacity of the compressor (e.g., highly efficient screw compressors for large-scale capacities or robust piston compressors for more compact units), the precise condenser type (air-cooled for areas with limited water, water-cooled for higher efficiency, or evaporative-cooled for optimal performance), and the intrinsic efficiency of the heat exchange surfaces within the evaporator. Advanced control systems, almost universally based on Programmable Logic Controllers (PLCs), facilitate an unparalleled level of precise management over the entire ice-making cycle, including optimized defrosting phases and efficient ice harvesting, thereby fine-tuning energy consumption and rigorously ensuring consistent ice quality. These sophisticated systems are often designed with seamless integration capabilities into broader factory automation networks, enabling comprehensive remote monitoring and control functionalities. For instance, real-time operational data such as instantaneous ice production rates, precise power consumption metrics, and immediate potential fault diagnostics can be accessed remotely, facilitating proactive and predictive maintenance strategies that significantly minimize costly downtime. This elevated level of technical sophistication is a defining hallmark of modern commercial tube ice machine offerings, providing operators with granular control, invaluable operational insights, and comprehensive diagnostic capabilities, which collectively maximize overall efficiency and ensure continuous operational uptime. Understanding the nuanced technical data is crucial for anyone seeking a premium tube ice machine for sale that delivers consistent, reliable performance in demanding industrial environments, truly maximizing their cooling efficiency.

Diverse Application Scenarios and Operational Advantages

The inherent versatility of a tube ice machine empowers its deployment across an exceptionally broad spectrum of industries and commercial applications, with each sector uniquely benefiting from tube ice's distinctive characteristics and the machine's robust design. These benefits often manifest as significant operational advantages, enhancing efficiency and product quality. Beyond these primary sectors, the versatility of a tube ice machine for sale extends to various niche markets where precise, reliable cooling is paramount.

Industry-Specific Use Cases

In the highly regulated food processing industry, the tube ice making machine is an indispensable asset for chilling raw meat, poultry, and seafood, effectively preserving freshness, inhibiting bacterial growth, and maintaining optimal product quality throughout the entire processing and transportation chain. Its non-clumping nature and uniform cylindrical shape ensure ease of handling and efficient mixing, making it ideal for direct contact with food products without causing damage. The chemical industry leverages tube ice for precise temperature control in highly exothermic reactions, intricate crystallization processes, and efficient solvent recovery, where maintaining stable and low temperatures is critically important for ensuring product quality, purity, and operational safety. Concrete cooling applications within the construction industry extensively utilize tube ice to meticulously control the hydration heat generated in large concrete pours, particularly for massive projects or in hot climatic conditions. This critical application prevents thermal cracking and guarantees the long-term structural integrity and durability of the concrete foundations and structures. Fisheries universally rely on tube ice for the meticulous preservation of their catches, both onboard fishing vessels immediately after harvest and at subsequent onshore processing plants, thereby ensuring the highest quality of seafood from the point of catch all the way to the consumer market. Furthermore, in specialized pharmaceutical manufacturing processes, tube ice can be strategically employed for chilling sensitive ingredients, maintaining precisely low temperatures during specific chemical syntheses, or for controlled cooling in lyophilization (freeze-drying) processes. The distinct cylindrical shape and large surface area-to-volume ratio of tube ice enable remarkably efficient heat transfer, making it a superior and often indispensable choice over other ice forms for a multitude of demanding industrial chilling requirements, contributing significantly to process optimization and product quality across these diverse sectors. The adaptability of a tube ice machine for sale makes it an invaluable asset across a multitude of sectors, providing tailored cooling solutions that address specific operational challenges.

Energy Efficiency and Corrosion Resistance

The advanced engineering and design of modern commercial tube ice machine units fundamentally prioritize both superlative energy efficiency and unparalleled long-term durability, directly and positively impacting operational costs and significantly enhancing the return on investment for businesses. Superior energy efficiency is systematically achieved through the implementation of several key technological innovations: the strategic utilization of high-efficiency scroll or robust screw compressors, meticulously optimized condenser and evaporator designs engineered for maximum heat exchange capability, and sophisticated intelligent control systems that dynamically adapt to varying operational load conditions. For example, a meticulously engineered tube ice machine for sale, when operating under ideal conditions, can achieve specific power consumption as remarkably low as 60-70 kWh per ton of ice produced. This is a significantly lower consumption rate compared to many conventional or older industrial ice production methods, directly translating into substantial and continuous energy cost savings over its extended operational lifespan. This high level of efficiency is often rigorously backed by verifiable third-party test data and internationally recognized certified performance ratings, providing tangible proof of their economic advantages. Hand-in-hand with this efficiency is an emphasis on superior corrosion resistance, which is absolutely paramount for machinery consistently operating in wet, often saline, or chemically exposed industrial environments. The exclusive use of premium-grade stainless steel (specifically SS304 or SS316) for all critical components that come into direct contact with water or ice, complemented by advanced surface treatments and durable protective coatings for external structures, ensures maximum resistance to rust, degradation, and microbial growth. This unwavering focus on selecting and applying durable, anti-corrosive materials translates directly into significantly minimized maintenance requirements, a substantially extended equipment life, and a dramatically reduced total cost of ownership over the machine’s operational tenure, making these machines an exceptionally robust, reliable, and economically sound choice for the most demanding industrial applications globally.

Comparative Analysis of Tube Ice Machine Solutions

When endeavoring to source a tube ice machine for sale, executing a thorough and comprehensive comparative analysis of the various available solutions and respective manufacturers is absolutely critical for judiciously selecting the optimal system that aligns perfectly with specific operational requirements and long-term strategic goals. This analytical process extends far beyond merely comparing the initial purchase price, delving instead into a holistic evaluation of the Total Cost of Ownership (TCO). This TCO calculation meticulously encompasses long-term factors such as projected energy consumption rates, anticipated maintenance frequencies and costs, and the expected operational lifespan of the equipment. Key differentiating factors among various manufacturers frequently include the intrinsic quality of their core components (e.g., the brand and type of compressors, condensers, and evaporators), the sophistication of their automation and control systems (ranging from advanced PLC-based systems with intuitive Human-Machine Interfaces to more conventional relay logic controls), and the extent and reliability of their after-sales support and warranty provisions. Reputable manufacturers often proudly display industry-specific certifications such as ISO (International Organization for Standardization) for quality management, CE (Conformité Européenne) marking for European market compliance, and sometimes specialized approvals like HACCP (Hazard Analysis and Critical Control Points) for food-grade systems, all serving as authoritative indicators of product quality and safety. Their global or regional service networks, guaranteed availability of genuine spare parts, and swift response times for technical support are equally vital considerations that directly impact operational uptime and profitability. The table below presents a conceptual comparison matrix, highlighting crucial aspects to meticulously consider when evaluating different commercial tube ice machine vendors or specific models. This detailed comparison emphasizes critical distinctions that can profoundly impact long-term operational efficiency, reliability, and ultimately, the overall value proposition, empowering B2B decision-makers to make exceedingly well-informed choices grounded in a holistic understanding of true value and sustainable performance. The total cost of ownership for a tube ice machine for sale is a critical consideration that smart buyers prioritize.

| Feature/Aspect | Vendor A (Example) | Vendor B (Example) | Vendor C (Example) |

|---|---|---|---|

| Compressor Brand | Bitzer/Danfoss | Copeland/Frascold | Local OEM |

| Evaporator Material | SS304/SS316 | SS304 | Galvanized Steel |

| Control System | Siemens PLC with HMI | Standard Relay Logic | Basic Microcontroller |

| Energy Efficiency (kWh/Ton) | 65-75 | 75-85 | 85-100+ |

| Warranty Period (Major Parts) | 24 months | 12 months | 6 months |

| Certifications | ISO, CE, HACCP | ISO, CE | None specified |

The judicious choice of a tube ice making machine should also comprehensively factor in the manufacturer's established track record, the breadth and responsiveness of their service network, and their proven ability to provide highly customized solutions that precisely fit unique operational needs. A vendor possessing extensive, specialized experience within your specific industry sector can offer invaluable insights and meticulously tailored recommendations, thereby ensuring the new system integrates seamlessly and efficiently with your existing operational infrastructure. Furthermore, a critical assessment should be made regarding the ease of performing routine maintenance and the guaranteed availability of genuine spare parts, which are vital for minimizing downtime. Manufacturers who prioritize a modular design philosophy and offer comprehensive training programs for your in-house technical staff can significantly alleviate long-term operational headaches and substantially reduce ongoing maintenance costs. Ultimately, the paramount consideration is that the best tube ice machine for sale is not merely one that meets your current production quotas, but crucially, one that offers robust, unwavering reliability, exceptional energy efficiency, and scalable, responsive support for future growth, thereby minimizing the total cost of ownership and maximizing continuous operational uptime in dynamic and demanding industrial environments.

Customization and Tailored Solutions

Acknowledging the indisputable fact that every industrial application possesses distinct and often highly specialized requirements, reputable manufacturers of tube ice machines offer extensive and flexible customization options for their commercial tube ice machine products. This meticulously bespoke approach is designed to ensure that the resultant system not only integrates flawlessly into existing infrastructure but also precisely meets and exceeds specific operational demands, thereby optimizing performance and efficiency. Customization capabilities are broad and can involve fine-tuning the daily ice production capacity, allowing for tailored solutions ranging from smaller-scale requirements of a few tons per day to immense industrial outputs comfortably exceeding 100 tons daily, ensuring scalability. Clients retain the flexibility to specify the exact desired ice tube diameter and length, which can be optimized for particular applications; for instance, smaller tubes may be preferred for rapid beverage cooling, while larger, more robust tubes are ideal for concrete cooling applications where thermal mass is critical. The selection of refrigerant type can be scrupulously tailored to adhere to local environmental regulations or specific client preferences, including highly efficient options for ammonia (NH3) for very large industrial systems (known for its superior thermodynamic properties), or environmentally compliant HFC refrigerants like R404A or R507. Furthermore, the condensing units can be custom-configured as air-cooled (an excellent choice for areas with limited water availability), water-cooled (offering higher efficiency where water resources are abundant), or advanced evaporative-cooled systems (providing optimal efficiency with significantly lower water consumption). Beyond these core adjustments, specialized materials such as SS316 can be specifically employed for enhanced corrosion resistance in exceptionally harsh chemical processing environments, guaranteeing longevity and durability. Integration with existing chilling or automated packaging systems, development of custom-designed control panel interfaces for intuitive operation, and even the provision of mobile or container111ized units for remote or temporary operations are common, sophisticated requests that can be accommodated. This unparalleled flexibility in design and manufacturing ensures that the acquired tube ice machine for sale is not merely an off-the-shelf product but rather a precision-engineered, purpose-built solution. Such a tailored machine is meticulously designed to deliver optimal performance, maximize efficiency, and contribute significantly to the client's unique operational landscape, thereby serving as a strategic asset that supports long-term sustainability goals and operational excellence.

Real-World Application Case Studies and Client Success

The practical efficacy, unwavering reliability, and profound economic benefits of a tube ice making machine are most compellingly demonstrated through authentic, real-world application case studies and validated testimonials from highly satisfied clients who have leveraged this technology. For instance, a prominent food processing plant situated in Southeast Asia recently undertook a significant upgrade of its chilling infrastructure by integrating a high-capacity 50-ton per day tube ice machine for sale. This strategic investment yielded remarkable results, specifically a verifiable 20% reduction in their overall chilling costs, attributable to both the machine's enhanced energy efficiency and a notable reduction in ice wastage during handling and application. Furthermore, the rapid cooling capability inherently provided by the tube ice significantly enhanced product freshness and demonstrably extended the shelf life for their processed poultry products, directly contributing to a measurable increase in their market share and customer satisfaction. Another compelling example emerges from a colossal concrete construction project initiated in the intensely hot climate of the Middle East, where a high-capacity commercial tube ice machine was strategically deployed to provide a continuous and reliable supply of chilling for massive concrete pours. This critical application successfully prevented thermal cracking, a common and severe issue in such environments, thereby ensuring the structural integrity and long-term durability of the foundational elements. The client meticulously reported consistent concrete quality and strict adherence to challenging project timelines, unequivocally attributing a substantial portion of this success to the dependable and consistent ice supply provided by the machine. Moreover, a major fishing fleet operating in the rigorous conditions of Northern Europe implemented tube ice machines directly onboard their vessels, resulting in a drastic improvement in the preservation of their catch from the very moment it was hauled in. This innovation led to significantly higher quality fish reaching the market, consequently commanding premium prices and substantially boosting the fleet's profitability. These diverse, yet equally compelling, examples powerfully underscore the inherent versatility, exceptional efficiency, and tangible, transformative benefits that a meticulously chosen tube ice machine can deliver across a broad spectrum of demanding industrial applications, unequivocally showcasing how such advanced technology directly translates into operational excellence and profound economic advantages for businesses committed to optimizing their cold chain and cooling processes.

Frequently Asked Questions (FAQ) about Tube Ice Machines

Q1: What is the typical lifespan of a Tube Ice Machine?

A1: With proper installation, diligent and regular preventative maintenance, and the exclusive use of high-quality, durable components sourced from reputable suppliers, a tube ice making machine can consistently demonstrate an impressive operational lifespan ranging from 10 to 15 years, and frequently even longer. Key factors profoundly influencing its longevity include the intrinsic quality of the construction materials (e.g., the grade of Stainless Steel 304/316 used for critical components), the brand and reliability of the refrigeration components (such as compressors and condensers), and strict adherence to the manufacturer's recommended maintenance schedules, including timely inspections and part replacements.

Q2: How energy-efficient are these machines?

A2: Modern commercial tube ice machine units are specifically engineered to be remarkably energy-efficient, often consuming between 60 to 85 kWh per ton of ice produced. This efficiency is contingent on various operational factors, including ambient and water temperatures, and the specific design and optimization of the machine's refrigeration cycle. High efficiency is achieved through the integration of advanced compressors, highly optimized heat exchangers, and intelligent, adaptive control systems that minimize energy consumption across varying load conditions, offering significant long-term operational cost savings.

Q3: Can a Tube Ice Machine be customized for specific industrial needs?

A3: Absolutely. Reputable manufacturers offer extensive and highly flexible customization capabilities for a tube ice machine for sale. This includes precise adjustments to daily production capacity, specific ice tube dimensions (diameter and length), choice of refrigerant type (e.g., R404A, R507, Ammonia), selection of condensing method (air-cooled, water-cooled, or evaporative), material upgrades for enhanced durability (e.g., to SS316 for corrosive environments), and seamless integration with existing plant automation systems, ensuring a tailor-made solution for unique operational requirements.

Q4: What maintenance is required for a Tube Ice Machine?

A4: Regular and systematic maintenance is crucial to ensure optimal performance and longevity. This typically includes periodic checks of refrigerant levels, thorough cleaning of the condenser (especially vital for air-cooled units to maintain heat transfer efficiency), meticulous inspection of all electrical connections for integrity, lubrication of any moving parts (though most modern designs minimize these), and routine descaling of the evaporator surfaces to prevent mineral buildup and maintain ice production efficiency. Most manufacturers provide a comprehensive, detailed maintenance schedule tailored to their specific models.

Q5: What are the key advantages of tube ice over other forms of ice?

A5: Tube ice offers several distinct advantages. Its cylindrical shape with a hollow center provides a remarkably large cooling surface area, enabling rapid and highly efficient cooling of products. This unique form factor also promotes excellent airflow when stored in bulk and inherently prevents clumping, making it exceptionally easy to handle, transport, and dispense. Furthermore, tube ice melts significantly slower than other forms of ice such as flake or crushed ice, thereby retaining its cooling power for extended periods, which is profoundly beneficial for various industrial applications where sustained cold temperatures are required over time, leading to less ice consumption and more consistent cooling.

Procurement and Support Information

When contemplating a substantial capital investment such as a tube ice machine for sale, a comprehensive understanding of the entire procurement process and the robust support structures offered by the manufacturer is absolutely paramount for mitigating risks and ensuring a successful long-term partnership. Reputable manufacturers typically offer a highly streamlined procurement process that commences with a detailed consultative phase, during which their experts meticulously assess your specific operational requirements, current infrastructure, and future scalability needs. This is followed by a precise system design proposal, a transparent quotation, the manufacturing phase, rigorous multi-stage quality inspections, and finally, coordinated delivery and comprehensive installation support. The typical delivery cycle for a standard tube ice making machine can range from 4 to 8 weeks, although this timeframe may extend for highly customized systems or during periods of high production demand. Leading suppliers universally provide comprehensive warranty commitments, typically offering a minimum of 12 to 24 months for the entire machine, with extended warranties (often 3-5 years) for major, high-value components such as the compressor unit. This robust commitment serves as a tangible demonstration of the manufacturer's unwavering confidence in their product quality and provides prospective buyers with significant peace of mind. Beyond the initial warranty period, resilient and responsive customer support is critically important. This encompasses readily available technical assistance (often via multiple channels like phone, email, and online portals), guaranteed availability of genuine spare parts for expeditious repairs, advanced remote diagnostics capabilities to minimize on-site visits, and potentially on-site service provided by highly skilled and certified technicians for complex issues. Potential buyers seeking a reliable tube ice machine for sale should prioritize vendors offering an established global or strong regional service network, coupled with comprehensive after-sales training programs tailored for their operational staff. A robust and comprehensive support framework ensures minimal operational downtime, optimized machine performance throughout its long operational life, and makes the investment in a commercial tube ice machine a truly reliable, productive, and future-proof asset for your business.

Conclusion

In conclusion, the strategic investment in a high-quality tube ice machine for sale unequivocally represents a pivotal decision for businesses across a diverse array of industrial sectors seeking not merely efficient ice production, but also reliable, hygienic, and sustainable cooling solutions. The meticulous attention to manufacturing excellence, coupled with stringent multi-stage quality control protocols and steadfast adherence to international standards such as ISO 9001, FDA, CE, and ASME, alongside the judicious incorporation of premium materials like SS304 and SS316, collectively guarantees not only long-term durability but also consistently superior performance. Modern tube ice machines are engineered to excel in energy efficiency, delivering substantial operational cost savings through optimized power consumption rates that can be as low as 60-70 kWh per ton of ice. Their inherent versatility renders them indispensable for a wide range of critical applications, extending from precise process cooling in the demanding petrochemical and metallurgical industries to the essential preservation of food products and meticulous temperature control in large-scale concrete construction. The availability of comprehensive customization options ensures that each machine can be precisely tailored to meet unique and evolving operational demands, thereby enhancing overall system integration and maximizing efficiency within existing infrastructures. Furthermore, the provision of robust after-sales support—encompassing transparent delivery cycles, extensive warranty commitments, and readily available, responsive technical assistance—serves to safeguard the initial investment and significantly minimizes potential operational downtime. By meticulously prioritizing these fundamental factors, businesses are empowered to acquire a tube ice solution that not only proficiently meets their immediate production requirements but also stands as a reliable, cost-effective, and environmentally sustainable asset, ultimately driving operational excellence and fostering long-term profitability within an increasingly competitive and demanding global market.

References

- ASHRAE Handbook—Refrigeration (I-P Edition). (2022). American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

- International Institute of Refrigeration. (IIR). (Ongoing publications). Key trends and innovations in industrial ice production.

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- Food and Drug Administration (FDA) CFR Title 21 - Food and Drugs.

- European Parliament and Council. (2014). Regulation (EU) No 517/2014 on fluorinated greenhouse gases (F-gas Regulation).

-

The Role of Modern Ice Machines in Food, Beverage, and Industrial ApplicationsNewsAug.24,2025

-

Next-Generation IQF Solutions: From Small IQF Freezer to Emergency Cold Storage TechnologiesNewsAug.24,2025

-

Advanced Refrigeration Technology: From Airtight Freezer Machine to Intelligent Cold Storage SolutionsNewsAug.24,2025

-

Reliable Cold Storage Rooms for Sale and Modern Industrial Refrigeration SolutionsNewsAug.24,2025

-

Reliable Coolroom for Sale and Advanced Cold Storage SolutionsNewsAug.24,2025

-

Cold Room Cost And Refrigeration Solutions From Shijiazhuang XuexiangNewsAug.24,2025