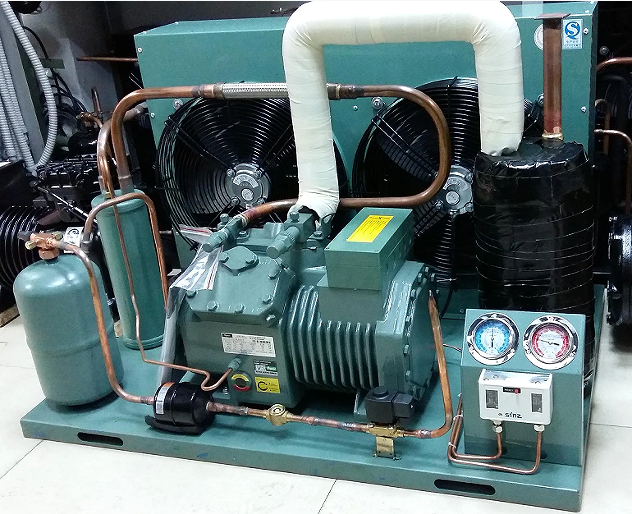

- The diameter of the copper pipe should be selected in strict accordance with the suction and discharge valve interface of the compressor. When the condenser and compressor separation of more than 3 meters should increase the diameter of the pipeline;

- The condenser suction surface and the wall to maintain more than 400mm distance, the outlet and obstacles to maintain a distance of more than 3 meters;

- The inlet and outlet pipe diameters of the liquid storage tank shall be subject to the exhaust and liquid outlet pipe diameters marked on the unit sample.

Apr . 01, 2024 10:14

Back to list

6 Points for Cold Room Installation Requirements and Do’s and Don’ts

Latest news

-

Transform Operations with Vacuum Freezer MachineNewsMay.14,2025

-

Enhance Business with Cold Room TechnologyNewsMay.14,2025

-

Vacuum Freezer Machine for Modern NeedsNewsMay.09,2025

-

Discover Our Comprehensive Cold Room SolutionsNewsMay.09,2025

-

Cold Room Solutions for Your BusinessNewsMay.08,2025

-

Advanced Vacuum Freezer MachineNewsMay.08,2025

Related PRODUCTS

Copyright © 2025 Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy