Chicken Cold Storage Solution

What Is Cold Storage Warehousing?

Cold storage warehousing involves the storing of perishable or other sensitive goods like food, medicines, and artwork at a specific temperature range to maintain their integrity, shelf-life, and quality.

Who Needs Cold Storage?

Any product or item that can degrade easily or lose its integrity when subjected to temperature fluctuations needs cold storage.

Chilling or freezing these sensitive goods helps slow their physical and chemical changes, which preserve their purity while inhibiting biological decay.

The ultimate goal of cold storage warehousing is to allow the movement of these products to end-users while maintaining the highest quality.

Specific Products That Require Cold Storage

-

Foods like fresh produce, meat and seafood, dairy, processed foods, and frozen foods

-

Nutritional supplements like perishable nutrient products

-

Botanicals such as flowers and plants

-

Bio-pharmaceuticals like medicines, vaccines, blood samples, IVs, and certain dental materials

-

Books and artwork like historical documents, paintings, and film canisters

-

Craft goods like candles (as they can lose their shape or color or melt if kept in high heat)

-

Cosmetics such as lipstick and cologne

-

Chemicals like reagents and disinfectants (these require cold storage to slow down their chemical reactions)

-

Organic textiles including fur, wool, and hides

-

Specialized products like aircraft components

Specific Industries That Use Cold Storage

-

Restaurants and food outlets

-

Supermarkets and food service firms

-

Importers and exporters

-

Frozen food producers

-

Agricultural producers

-

Pharmaceuticals and healthcare institutions

How Big Is the Cold Storage Industry?

Cold storage is a key player in the industrial real estate sector.

Here are some key facts about its size in the United States:

-

Cold storage accounted for 3.6 billion cubic feet of all warehouse space in 2017

-

The market size of cold storage facilities was valued at $30.26 billion in 2021

-

California, Washington, and Florida are the 3 states with the highest cold storage volume

Why Is Cold Storage Becoming So Popular?

The cold storage market is expected to expand at a compound growth rate (CAGR) rate of 9.2% between 2022 and 2030.

But what’s causing the increase in popularity?

Here are 3 key factors:

1. Changing Consumer Preferences

Many consumers’ eating habits are changing.

For instance, more folks are avoiding processed, canned, and packaged foods and instead consuming freshly prepared kitted meals.

More consumers are buying kitted meals, driving up demand for cold storage

And these pre-prepared meals require careful temperature control for preservation – hence the need for more cold storage.

2. Population Growth

By 2026, projections show that 20 million more people will be living in the U.S.

And more people means more mouths to feed, more medicine to supply, and more goods demanded.

Thus, there’s more need for cold storage facilities to accommodate these demands.

3. Increased Spending

There’s been a general increase in consumer spending due in part to the rise of E-commerce.

This includes spending on refrigerated products like food, pharmaceuticals, and cosmetics.

Of course, the more of these items that are sold, the greater the need for cold storage

How Do Cold Storage Warehouses Work?

Cold storage warehouses maintain cooler temperatures through a combination of insulation and HVAC cooling systems.

Insulation serves the same purpose for cold storage warehouses as it does for houses: It helps limit the transfer of heat between the inside and the outside.

On the other hand, cooling systems for cold storage warehouses are a bit more complex.

But the basic idea is that they use a combination of coolant, pipes, radiators, and fans to absorb and remove heat and replace it with cooler air.

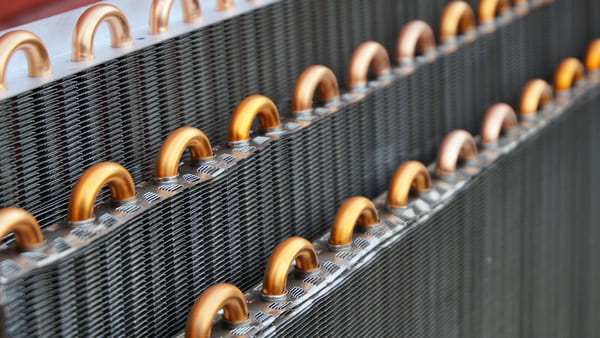

The Main Cold Storage Cooling System Components

THE COOLANT

If you think of a cold storage warehouse cooling system as a mechanical human body, the coolant (also called a “refrigerant”) is like the blood.

That’s because it’s made of liquid (typically anhydrous ammonia) and circulates throughout the system via a series of tubes, pipes, and components – much like blood does through veins, arteries, and organs.

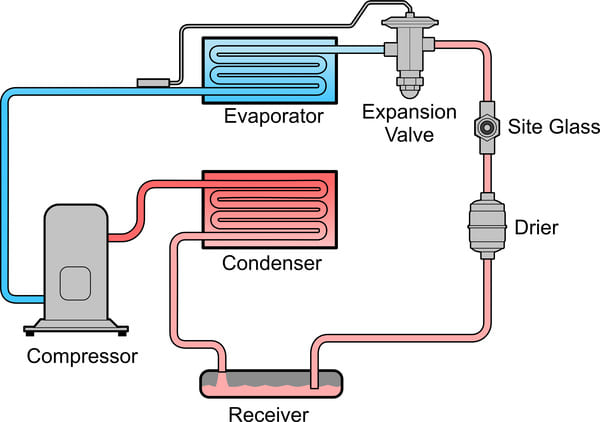

THE COMPRESSOR

This is the main component in a cold room cooling system.

If the coolant is the “blood,” the compressor is similar to the “heart” in that it helps move the coolant.

It does so by raising the coolant pressure and temperature through compression and then pumps the heated refrigerant into the condenser.

THE CONDENSER

The condenser removes heat from the refrigerant and disperses it into the atmosphere using tubes, fans, and/or water spray.

In the process, the refrigerant changes state from a gas to a liquid and then flows into the receiver.

THE RECEIVER

The receiver stores the high-pressure liquid coolant condensate it gets from the condenser.

Through this, the receiver allows the whole system to maintain pressure while also providing a buffer for handling increased loads, such as when more cool air is needed.

Fruits And Vegetables Cold Room

When needed, the receiver releases the refrigerant into an expansion valve.

The expansion valve helps regulate the pressure, temperature, and amount of refrigerant released into the next component – the separator.

THE SEPARATOR

The separator receives and accumulates refrigerant from the receiver.

Pumps outside the separator pull the refrigerant into another expansion valve, where the flow rate is adjusted before it enters the evaporator.

The pumps also help adjust the load placed on the evaporator, which is determined by the cooling needs in the warehouse.

THE EVAPORATOR

The evaporator is what brings cold air into the space being cooled and causes the temperature to drop.

It does this by passing the cold refrigerant through a series of tubes while a fan blows air from the space across the tubes.

The cold refrigerant in the tubes absorbs the heat, and the air leaves the evaporator cold – thus chilling the room and the goods.

Once the coolant does its cooling job in the evaporator, the refrigerant makes its way back to the first component (the compressor) and the whole cooling process starts over again.

How Cold Is a Chilled Warehouse?

Cold storage warehouse temperatures are broad but normally range from -30° to 70° F.

Warehouses that handle frozen goods can be as cold as -122.8° F (for ultra-low temperature pharmaceutical warehouses).

But the most common freezer temperature range is between -10 and -20° F.

What Is the Difference Between Cold Storage, Climate-Controlled, and Temperature-Controlled Warehouses?

Cold storage is a type of temperature-controlled warehouse that restricts temperatures to a certain specific range but does not control humidity

Climate-controlled warehouses restrict both temperature and humidity levels to certain specific ranges

How Many Types of Cold Storage Are There?

There are 2 main types of cold storage:

- Refrigerated cold storage

- Frozen cold storage

Here’s a summary of each one’s characteristics:

Refrigerated cold storage facilities (sometimes called “refrigerated warehouses“) are designed for preserving the integrity and shelf life of products that don’t need to be frozen.

They are typically kept between 33° and 55° F and store products such as fruits and vegetables.

On the other hand, frozen cold storage facilities help preserve the integrity and safety of items that must be frozen.

Temperatures in these freezer storage facilities can be up to 32° F, making them ideal for storing products like meat, fish, and produce.

5 Cold Storage Warehouse Examples

Although there are 2 main types of cold storage warehouses, there’s still a lot of variation among them.

So let’s go over a few common cold storage warehouse examples.

1. Private Cold Storage

The defining characteristic of private cold storage warehouses is that they’re owned by the same enterprise that uses or produces the goods stored in the facility.

In practice, they’re commonly found connected to the main manufacturing facility and receive the just-made via conveyor.

Once inside the cold storage facility, the products are held until they’re ready to be sent to retailers or directly to the end-users.

Of all types of cold storage warehouses, private ones are less common.

This is largely because of the expensive nature of building and running them, which involves complex design and engineering plus compliance with many regulations.

As a result, they’re reserved for large companies like Nestle and Kraft.

While more expensive, the main benefit of owning a private cold storage warehouse is the greater control and flexibility it provides over products and how they’re handled.

This can help producers maintain quality, find areas to reduce costs, and ultimately improve customer satisfaction by ensuring a superior product.

2. Public Cold Storage

Public cold storage is a type of cold storage warehouse that’s usually owned and operated by 3rd-party logistics (3PL) companies.

Unlike private cold storage warehouses, public ones receive, store, and ship goods on behalf of client companies.

For example, a fresh flower distributor might pay a 3PL cold storage facility to receive their products, hold them in storage until orders are received, then load them onto delivery trucks.

In addition to basic warehousing storage, many public cold storage facilities also offer a variety of value-added services.

This can include things like assembling or kitting, placing inserts in packages, or providing expanded quality control.

Public cold storage is the most common type of cold storage warehouse in the United States.

And the reason for its popularity is that owning and running a cold storage facility is a massive, expensive, and complex undertaking.

Furthermore, handling logistics isn’t every company’s strong suit.

Thus, those that recognize this also realize the value of partnering with a logistics specialist whose strong suit it is.

That way, each company can focus on other, more pressing concerns like product development, marketing, and sales.

3. Refrigerated Containers

A refrigerated container is the most basic and inexpensive cold storage option for storing small quantities of temperature-sensitive products.

They are essentially shipping containers equipped with diesel-electric or grid-electric cooling units that can maintain temperatures between -30° and 70° F.

Refrigerated containers are the simplest, most flexible type of cold storage

Also highly customizable, refrigerated containers can be outfitted with features like different floor types, indoor lighting, and remote temperature monitoring.

Furthermore, because of their relatively small size (most are between 10 and 40 feet long), they are highly mobile.

For example, they can be placed inside a warehouse, outside, or at dock level, as well as on a trailer chassis – whatever setup is needed to accommodate the user’s specific needs.

4. Blast Freezers

Also called “blast chillers,” “shock freezers,” or “flash freezers,” these are very cold freezers used to rapidly chill products before placing them in longer-term storage.

Blast freezers are often used at the intermediate stage between production and storage.

For example, they’re useful when warm goods like bakery items straight from a production line oven need to be chilled quickly before moving to a longer-term cold storage facility.

How does it work?

Blower fans are used to force chilled air over products, which can result in bringing the temperature down from 160° to 41° F in about 90 minutes.

This helps preserve the attributes like nutrients, texture, flavor, and shelf life while also reducing bacterial growth.

Moreover, it helps reduce the strain on conventional cold storage cooling systems, which are less efficient when trying to lower the temperature of very warm goods.

5. Ultra-Low Temperature Cold Storage

Ultra-low temperature (ULT) cold storage is designed for storing sensitive biological and research specimens at temperatures ranging from -4° to -122.8° F.

ULTs gained exposure during the COVID-19 pandemic as it became known that they were required for safely storing the vaccines.

Besides vaccines, they are used for storing items like medicines and blood and tissue samples.

Compared to other types of cold storage on this list, ultra-low temperature cold storage accounts for a much smaller portion of the entire cold storage industry.

Furthermore, ULTs tend to be smaller physically than conventional cold storage – usually 20,000 to 60,000 square feet versus 150,000 to 400,000 square feet for the latter.

They also function with the utmost precision to preserve highly-sensitive materials.

That includes using liquid nitrogen or carbon dioxide backup cooling systems if the primary cooling system fails.

In addition, many ULT facilities are equipped with robust monitoring systems like alarms, data logging, and remote temperature control to safeguard against system failures.

Chill Your Way with Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. Cold Room Solutions

Elevate your food preservation with Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. Cold Room's advanced cold storage systems. Our range includes state-of-the-art blast freezers, vacuum freezers, and more, designed to meet your specific needs.

Contact Us Now For expert advice and a quote tailored to your business, reach out to us at +86 193 5827 7191 or email us at cathyliu985@gmail.com.

Transform Your Storage Today Let's work together to enhance the quality and longevity of your products. Contact us for a seamless, efficient cold storage experience.