cold room for fish storage factories

Cold Room Solutions for Fish Storage Factories

In the modern seafood industry, the importance of maintaining the freshness and quality of fish cannot be overstated. With the global demand for seafood consistently rising, fish storage factories have turned to innovative cold room solutions to enhance their operations. A cold room, designed specifically for preserving fish and other perishable products, plays a crucial role in ensuring that fish remains safe for consumption while retaining its prized qualities.

The Necessity of Cold Rooms

Fish is a highly perishable item that can spoil rapidly if not stored at appropriate temperatures. The primary purpose of cold rooms in fish storage factories is to maintain a controlled environment where temperature and humidity levels can be regulated. These cold rooms typically operate at temperatures ranging from -1°C to 5°C, ensuring that the products are kept within the optimal range to slow down bacterial growth and enzymatic activity. This controlled environment not only extends the shelf life of the fish but also preserves its flavor, texture, and nutritional value.

Design and Features of Cold Rooms

The design of a cold room for fish storage involves careful consideration of factors such as size, insulation, and refrigeration systems. Insulation materials such as polyurethane or polystyrene are commonly used to minimize heat transfer, thus aiding in maintaining a stable internal temperature. Additionally, the layout should facilitate easy access for loading and unloading fish, without compromising the temperature control.

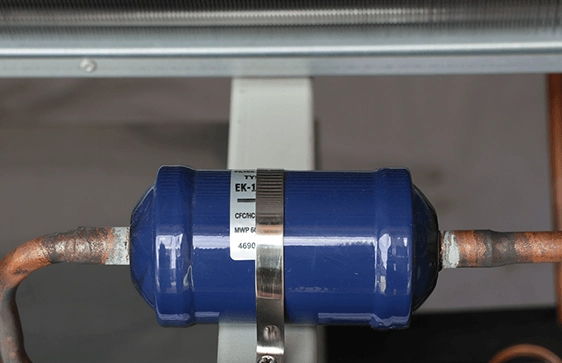

Modern cold rooms are often equipped with advanced refrigeration systems that efficiently maintain cold temperatures while using less energy. This energy efficiency is crucial, as the operational costs of a fish storage factory can be significantly impacted by the energy consumption of its refrigeration systems. Temperature monitoring systems are also essential; they provide real-time data on the conditions within the cold room, alerting operators to any fluctuations that may jeopardize the stored fish.

cold room for fish storage factories

Furthermore, humidity control is another important aspect, as it helps prevent the fish from drying out or developing ice crystals, which can adversely affect texture and taste. Some cold room systems include dehumidifiers to maintain optimal humidity levels, ensuring that the quality of the fish remains intact.

Compliance and Safety Standards

Fish storage factories must adhere to strict health and safety regulations to ensure that the fish remains safe for consumption. Cold rooms are subject to various food safety standards, which require regular inspections and maintenance. Proper cleaning protocols must be implemented to prevent contamination, and staff should be adequately trained to handle fish products safely.

The Future of Fish Storage

As the seafood industry continues to evolve, cold room technology is advancing as well. Innovations such as smart cold storage solutions, which use IoT devices for monitoring and automation, are becoming increasingly popular. These systems offer greater efficiency, reduced waste, and enhanced traceability in fish storage and handling.

In conclusion, cold rooms are indispensable in fish storage factories, ensuring the longevity and quality of seafood products. By investing in advanced cold room solutions, companies can meet the growing demand for fish while adhering to safety standards and maintaining the highest quality standards. As technology advances, the future of fish storage promises greater efficiency and sustainability, benefiting producers, consumers, and the environment alike.