Efficient Evaporator Units for Industrial Cold Storage Rooms and Refrigeration Systems

The Importance of Evaporator Units in Cold Room Factories

In today's rapidly advancing industrial landscape, the cold storage industry plays a pivotal role in preserving perishable goods, particularly in sectors such as food and pharmaceuticals. Central to the operation of cold room factories is the evaporator unit, a crucial component in the refrigeration system. Understanding the function and significance of these units can provide valuable insight into their indispensable role in maintaining optimal storage conditions.

An evaporator unit is designed to remove heat from the cold storage environment, ensuring that temperatures remain consistently low. This process is vital for the preservation of products that require refrigeration, such as meats, dairy products, fruits, and vegetables. By absorbing heat, the evaporator facilitates phase change from liquid refrigerant to gas, which is then circulated away from the cold room to cool the environment further. This heat exchange process is not only crucial for maintaining low temperatures but also for ensuring product quality and safety.

The Importance of Evaporator Units in Cold Room Factories

Furthermore, evaporator units contribute to the effectiveness of the entire refrigeration system. They are equipped with fans that facilitate the circulation of cold air throughout the cold room, promoting even temperature distribution. This uniformity is essential in preventing cold spots or warm areas, which can lead to spoilage of certain goods. Additionally, advanced evaporator models come with features such as adjustable airflow and humidity control, further enhancing their capability to maintain ideal storage conditions.

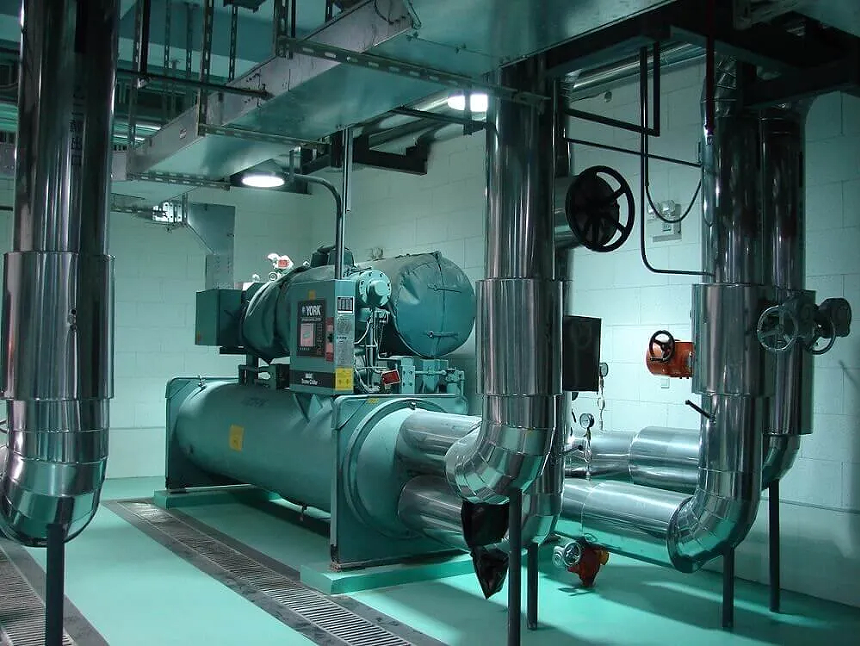

evaporator unit for cold room factories

Regular maintenance of evaporator units is also critical. Proper upkeep ensures longevity and optimal performance, preventing costly breakdowns that can disrupt operations. Maintenance tasks typically include cleaning the evaporator coils, checking refrigerant levels, and inspecting fan functionality. By establishing a routine maintenance schedule, cold room factories can prevent minor issues from escalating into significant problems, ensuring uninterrupted cold storage operations.

In terms of design and installation, evaporators come in various configurations to suit different types of cold room applications. Vertical, horizontal, and ceiling-mounted designs allow facilities to maximize space while ensuring efficient cooling. The choice of evaporator unit can also depend on factors such as the size of the cold room, the type of goods stored, and the desired temperature range. Collaborating with experienced HVAC professionals during the selection and installation process can lead to tailored solutions that meet specific operational needs.

Moreover, the impact of evaporator units extends beyond just operational efficiency; it plays a vital role in food safety and compliance with regulations. Governments and health organizations enforce strict guidelines regarding the storage temperatures of perishable goods to prevent foodborne illnesses. Reliable evaporator systems help facilities maintain these standards, ensuring that products are stored safely and reducing the risk of recalls or penalties.

In conclusion, evaporator units are essential to the successful operation of cold room factories, significantly affecting energy efficiency, product safety, and operational longevity. Their ability to maintain optimal temperature and humidity levels, combined with their contributions to energy savings, makes them a critical investment for businesses in the cold storage industry. As technology continues to evolve, the efficiency and effectiveness of evaporator units will only enhance, further solidifying their role as a cornerstone of modern refrigeration systems.