Efficient Semi Hermetic Condensing Units - HVAC-R Solutions

Navigating Industrial Refrigeration: Trends and the Ascent of Advanced Condensing Units

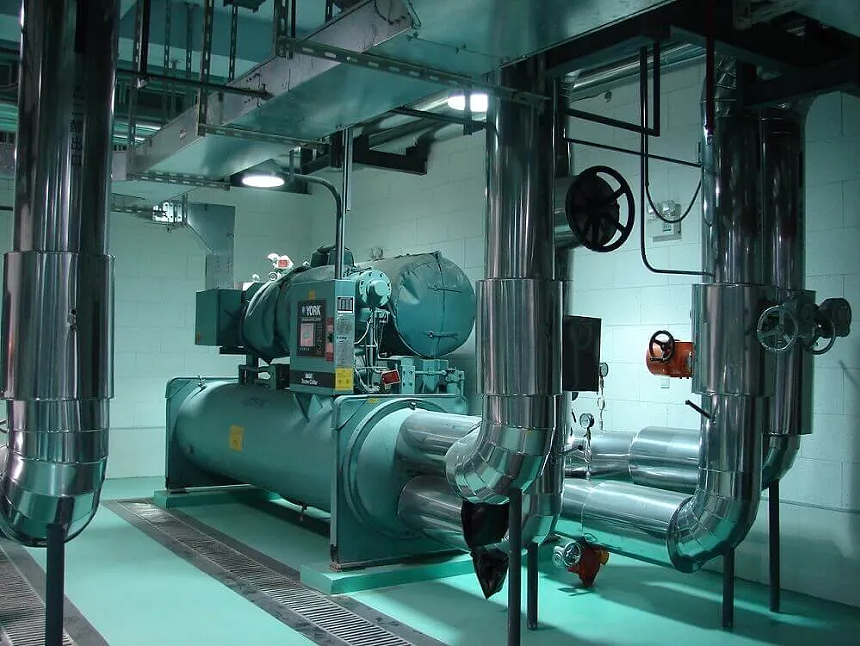

The industrial refrigeration landscape is currently experiencing a transformative phase, driven by a confluence of factors including stringent environmental regulations, escalating energy costs, and an unyielding demand for enhanced operational efficiency. Businesses across diverse sectors, from food processing and pharmaceuticals to chemical and logistics, are actively seeking robust, reliable, and sustainable cooling solutions. This pivotal shift highlights the growing prominence of sophisticated refrigeration components that not only meet current performance benchmarks but also anticipate future requirements. Among these, the semi hermetic condensing unit stands out as a cornerstone technology, offering a strategic balance between the serviceability of open-type systems and the inherent compactness of hermetic designs. Its adaptability to various refrigerants, coupled with superior efficiency and a longer operational lifespan, positions it as an indispensable asset for demanding industrial applications. The market trend indicates a clear preference for units that promise not just raw cooling capacity but also intelligent control, reduced environmental footprint, and lower total cost of ownership over their lifecycle. This segment is witnessing continuous innovation, particularly in compressor technology and integrated control systems, further solidifying its critical role in maintaining optimal thermal conditions across the global supply chain. The ability to perform complex maintenance on-site, a significant advantage over fully sealed units, greatly appeals to large industrial operators where downtime is extremely costly and operational continuity is paramount.

Understanding the Engineering Excellence: Bitzer Semi-Hermetic Open-Type Condensing Units

At the heart of modern industrial refrigeration lies the expertly engineered semi hermetic condensing unit. Unlike their fully sealed counterparts, which are typically discarded upon internal failure, semi-hermetic units feature bolt-on components, primarily the compressor, allowing for field serviceability and component replacement. This design philosophy significantly extends the unit’s operational life and reduces long-term maintenance costs. The Bitzer Semi-Hermetic Open-type Condensing Unit (-45~5℃), for instance, exemplifies this design, integrating a robust Bitzer compressor with meticulously selected auxiliary components such as condensers, liquid receivers, filter driers, solenoid valves, and high/low-pressure gauges. The unit’s open-type structure facilitates easy access for inspection and maintenance, which is crucial in high-demand environments. Manufacturing begins with the careful selection of high-grade materials, including specialized alloys for compressor casings and high-efficiency copper tubing for heat exchangers, ensuring durability and optimal thermal transfer. Precision manufacturing processes, including advanced CNC machining for critical components and automated brazing for pipe connections, guarantee structural integrity and leak-free operation. Each unit undergoes rigorous testing protocols, adhering to international standards such as ISO 9001 for quality management and ANSI/ASHRAE for performance validation. These units are designed for a projected service life exceeding 15-20 years under proper maintenance, a testament to their robust construction and the quality of their constituent parts. Their adaptability to various refrigerants, including eco-friendly options, underscores their versatility and alignment with evolving environmental regulations, making them a sustainable choice for long-term industrial applications.

The meticulous manufacturing process for a semi hermetic condensing unit involves several critical stages, beginning with the precision casting of the compressor body, often using high-strength ductile iron or aluminum alloys, followed by detailed forging for crankshafts and connecting rods to ensure extreme durability under continuous operation. Subsequent CNC machining operations ensure micron-level tolerances for moving parts, which is fundamental to achieving high volumetric efficiency and minimizing friction. The assembly phase occurs in controlled environments, where skilled technicians meticulously integrate the compressor with the condenser coil, often featuring fin-and-tube designs for maximized heat rejection, and the robust liquid receiver, designed to handle refrigerant charge variations. Welding and brazing processes are performed with advanced robotic systems to ensure uniform, strong, and leak-proof joints. Post-assembly, each unit undergoes comprehensive electrical testing, pressure testing with inert gases to detect the slightest leaks, and performance validation on a test bench, simulating various operating conditions. This includes run-in periods to ensure all components are properly seated and functioning optimally, and noise/vibration analysis to guarantee smooth operation. The adherence to strict quality control standards, such as those mandated by ISO and CE certifications, ensures that every unit delivered meets or exceeds the specified technical parameters and safety requirements. This rigorous approach not only extends the unit’s lifespan but also ensures its reliable performance in critical applications such as cold storage warehouses, pharmaceutical production facilities, and industrial process cooling.

Technical Parameters and Performance Benchmarks for Semi-Hermetic Units

The performance of a semi hermetic condensing unit is defined by a comprehensive set of technical parameters, which are crucial for engineers and decision-makers in specifying the right equipment for their applications. Key parameters include cooling capacity, measured in BTUs/hr or kW, which indicates the unit’s ability to remove heat from a space. Power input (kW) and coefficient of performance (COP) or energy efficiency ratio (EER) are vital indicators of energy consumption and efficiency, directly impacting operational costs. For instance, the Bitzer Semi-Hermetic Open-type Condensing Unit (-45~5℃) is engineered for broad temperature ranges, making it suitable for both medium and low-temperature refrigeration. Compressor type, such as reciprocating or screw, dictates the unit’s volumetric displacement, pressure ratio capabilities, and overall efficiency profile. Furthermore, the unit's compatibility with various refrigerants (e.g., R404A, R507A, R134a, R22, R448A, R449A) is critical for environmental compliance and operational flexibility. Noise levels (dB(A)) and dimensions (length, width, height) are also important considerations for installation and occupational health. Advanced models often feature integrated electronic controls that optimize compressor performance, manage defrost cycles, and provide real-time diagnostic data, enhancing reliability and predictive maintenance capabilities. Understanding these detailed specifications allows for precise system design and ensures that the refrigeration unit delivers optimal performance while adhering to stringent industry standards for energy consumption and environmental impact.

Example Technical Specifications Table: Bitzer Semi-Hermetic Condensing Unit

| Parameter | Typical Range / Value | Relevance |

|---|---|---|

| Cooling Capacity | 10 kW - 150 kW (Variable) | Determines the heat removal capability. Critical for matching load. |

| Evaporating Temperature Range | -45°C to +5°C | Suitable for diverse applications from freezing to chilling. |

| Compressor Type | Bitzer Reciprocating / Screw (e.g., 4GE-30Y, 6FE-50Y) | Influences efficiency, noise, and vibration characteristics. |

| Refrigerant Compatibility | R404A, R507A, R134a, R22, R448A, R449A | Ensures compliance with environmental regulations and flexibility. |

| Power Supply | 3 Phase, 380V/50Hz (Customizable) | Must match local electrical infrastructure for proper operation. |

| COP (Coefficient of Performance) | 2.5 - 3.5 (at specific conditions) | Higher COP indicates better energy efficiency. |

| Noise Level | ~65-75 dB(A) (depends on size/enclosure) | Important for installation in noise-sensitive areas. |

| Net Weight | 200 kg - 1500 kg+ | Influences logistics, installation requirements, and foundation design. |

The robust design of a semi hermetic condensing unit extends its applicability across a broad spectrum of industries, showcasing its versatility and efficiency. In the petrochemical industry, these units are critical for maintaining precise temperatures in chemical storage, reaction vessels, and refining processes, where consistency is paramount for safety and product quality. Their resistance to corrosive environments, often enhanced by specialized coatings and materials, ensures long-term reliability. Within metallurgy, they provide essential cooling for quenching processes, rolling mills, and induction furnaces, controlling heat to prevent material degradation and optimize production rates. For water supply and drainage systems, particularly in large-scale municipal or industrial operations, these units are employed in water treatment processes and to cool pump stations, ensuring the longevity of equipment and maintaining water quality standards. The inherent advantages, such as superior energy efficiency stemming from optimized compressor designs and advanced heat exchanger technology, translate directly into reduced operational costs. Furthermore, their modular design allows for scalability and easier integration into existing infrastructure, providing flexibility for facility expansions. The anti-corrosion properties, achieved through meticulous material selection and surface treatments, ensure the unit's integrity even in the harshest industrial settings, contributing to extended lifespan and minimal maintenance needs, ultimately enhancing overall operational resilience and sustainability.

Application Scenarios and Strategic Advantages in Key Industries

The strategic deployment of a semi hermetic condensing unit provides substantial operational and economic advantages across various industrial sectors. In the cold chain logistics, including large-scale cold storage warehouses and distribution centers, these units are fundamental for maintaining precise temperature and humidity conditions crucial for preserving perishable goods like food, pharmaceuticals, and sensitive chemicals. Their robust build ensures continuous operation, minimizing the risk of product spoilage and costly losses. For food processing plants, from meat and dairy to fruits and vegetables, accurate and consistent refrigeration is vital for product safety, quality, and extended shelf life, where semi-hermetic units offer the necessary reliability and capacity. In the pharmaceutical industry, the precise temperature control offered by these units is non-negotiable for drug manufacturing, storage of vaccines, and active pharmaceutical ingredients (APIs), where even slight temperature deviations can compromise efficacy and regulatory compliance. Furthermore, in specialized industrial processes such as plastics manufacturing, laser cooling, and data center cooling, the high efficiency and customizable nature of these units ensure optimal performance of production machinery and critical IT infrastructure by effectively dissipating process heat. The ability to tailor units for specific low-temperature applications, reaching down to -45°C, makes them ideal for blast freezing and cryogenic storage, which are essential for certain high-value products.

Beyond direct cooling, the advantages of a semi hermetic condensing unit extend to significant energy savings and reduced environmental impact. Modern units often incorporate variable speed drives (VSDs) and advanced control logic, allowing the compressor to operate at optimal efficiency based on the actual cooling load, drastically reducing electricity consumption compared to fixed-speed units. This translates into lower operational expenditures and a smaller carbon footprint, aligning with global sustainability initiatives. The use of environmentally friendly refrigerants, such as HFO blends with low Global Warming Potential (GWP), further enhances their ecological appeal. Companies like ours, with over 20 years of experience in the cold room industry, leverage this expertise to design systems that maximize the inherent benefits of semi-hermetic units, ensuring seamless integration and superior performance. Our extensive portfolio of service cases demonstrates successful implementations across a diverse client base, consistently delivering reliable refrigeration solutions that meet complex operational demands. Customer feedback frequently highlights the durability and cost-effectiveness of these systems, emphasizing their long-term value. We pride ourselves on transparent reporting of test data and performance metrics, providing clients with the confidence that their investment is backed by verifiable performance and proven reliability, which is paramount in critical industrial operations.

Comparative Analysis: Semi-Hermetic vs. Hermetic Condensing Units

When selecting a condensing unit, understanding the fundamental differences between a semi hermetic condensing unit and a hermetic condensing unit is crucial for optimal system design and long-term cost efficiency. Hermetic units, characterized by their completely sealed compressor and motor within a single welded casing, are generally more compact and cost-effective upfront for smaller to medium capacities. They offer simplicity and are often used in commercial applications like household refrigerators or smaller air conditioning units where maintenance is not anticipated or economically viable. However, their sealed nature means that any internal failure necessitates the replacement of the entire compressor, leading to potentially higher replacement costs and more significant downtime. In contrast, semi-hermetic units feature a bolted casing that allows for access to internal components like the motor, crankshaft, and valves. This design offers unparalleled flexibility for maintenance, repairs, and even component upgrades, significantly extending the unit’s operational life and reducing life-cycle costs. While typically larger and with a higher initial investment than hermetic units, their maintainability makes them the preferred choice for industrial and large commercial refrigeration systems where performance continuity and serviceability are paramount. The ability to perform in-situ repairs minimizes operational disruptions, an invaluable advantage for processes where consistent cooling is critical to product integrity and operational output.

Condensing Unit Comparison: Semi-Hermetic vs. Hermetic

| Feature | Semi-Hermetic Condensing Unit | Hermetic Condensing Unit |

|---|---|---|

| Serviceability | Field-repairable; internal components accessible. | Sealed unit; entire compressor replacement upon failure. |

| Lifespan | Extended lifespan due to repairability (15-20+ years). | Shorter lifespan (typically 5-10 years) due to non-repairability. |

| Initial Cost | Generally higher due to complex design and larger capacity. | Lower initial cost, simpler manufacturing. |

| Operating Efficiency | Higher efficiency for industrial loads, often with advanced controls. | Good for smaller loads, generally less flexible control. |

| Applications | Industrial refrigeration, large cold rooms, process cooling. | Small commercial, residential A/C, household appliances. |

| Capacity Range | Medium to very high capacities (e.g., 10 kW to 500+ kW). | Small to medium capacities (e.g., 0.5 kW to 30 kW). |

The choice between a semi hermetic condensing unit and a hermetic unit largely depends on the specific demands of the application, including required cooling capacity, budget constraints, anticipated lifespan, and importance of uninterrupted operation. For most industrial and heavy commercial refrigeration needs, the advantages of serviceability, higher efficiency, and longer lifespan offered by semi-hermetic units far outweigh their higher initial cost. This is particularly true for facilities where downtime is economically devastating, such as pharmaceutical manufacturing or large-scale food processing. Our experience working with numerous enterprises underscores this point: the total cost of ownership (TCO) for a well-maintained semi-hermetic system is often significantly lower over its operational life compared to repeatedly replacing hermetic units. This commitment to long-term value, combined with our ability to provide customized solutions, positions us as a trusted partner for businesses seeking optimal refrigeration performance. We collaborate closely with clients to assess their unique operational demands, refrigerant preferences, and environmental considerations to recommend and implement the most suitable and cost-effective condensing unit solutions.

Customized Solutions and Unwavering Commitment to Trustworthiness

Recognizing that no two industrial refrigeration needs are identical, our approach focuses on delivering highly customized semi hermetic condensing unit solutions. This involves a comprehensive analysis of the client's specific operational parameters, including target temperature range, required cooling capacity, ambient conditions, available space, and integration with existing control systems. We specialize in tailoring Bitzer Semi-Hermetic Open-type Condensing Units, configuring them with optimal condenser designs, fan types (axial or centrifugal), and control panel functionalities to precisely meet unique project demands. This includes selecting the most appropriate compressor model from Bitzer’s extensive range, optimizing refrigerant charge, and integrating advanced features like oil management systems, liquid injection, or heat recovery modules for enhanced efficiency. Our engineering team leverages decades of collective experience to design systems that not only perform reliably but also achieve optimal energy consumption. We also consider specific industry compliance requirements, such as FDA regulations for pharmaceutical storage or HACCP standards for food processing, ensuring that the customized unit seamlessly integrates into the client’s regulatory framework. Our commitment extends to providing detailed project documentation, including CAD drawings and performance curves, ensuring complete transparency and client understanding of their tailored refrigeration solution.

Our dedication to client satisfaction and operational excellence is underpinned by a robust framework of trustworthiness and authoritative practices. Each semi hermetic condensing unit we supply is backed by comprehensive industry certifications, including CE marking for European safety standards and adherence to ISO 9001 quality management systems. We maintain strong partnerships with leading component manufacturers like Bitzer, ensuring access to genuine parts and the latest technological advancements. Our service tenure, exceeding two decades in the refrigeration sector, speaks volumes about our stability and deep industry knowledge. We stand by our products with a clear warranty commitment, typically ranging from 12 to 24 months for major components, reflecting our confidence in their quality and durability. Our streamlined delivery process, often between 4 to 6 weeks depending on customization complexity, is meticulously managed to ensure timely project completion. Furthermore, our dedicated customer support team provides comprehensive post-installation assistance, including troubleshooting, preventative maintenance guidance, and prompt availability of spare parts, minimizing potential downtime and maximizing the operational lifespan of your investment. This holistic approach, combining expert design, certified products, and reliable support, builds lasting relationships with our B2B clientele, ensuring their critical refrigeration needs are met with unparalleled reliability and efficiency.

Frequently Asked Questions (FAQ) on Semi-Hermetic Condensing Units

Q1: What are the primary advantages of a semi-hermetic condensing unit over a hermetic one?

A1: The main advantages include field serviceability of the compressor, significantly longer operational lifespan, higher energy efficiency for larger capacities, and greater flexibility in terms of refrigerant compatibility and application temperature ranges. This leads to a lower total cost of ownership over the unit's lifetime, particularly for industrial and heavy commercial applications where reliability and uptime are critical.

Q2: What maintenance is typically required for a semi-hermetic condensing unit?

A2: Regular maintenance for a semi hermetic condensing unit involves routine checks of refrigerant levels, oil analysis and changes, filter drier replacement, condenser coil cleaning, and inspection of electrical connections and fan motors. The ability to access internal components also allows for more extensive repairs, such as valve plate replacement or motor winding servicing, which is not possible with hermetic units. Preventative maintenance schedules are crucial for maximizing lifespan and efficiency.

Q3: How does the operating temperature range affect the selection of a semi-hermetic unit?

A3: The desired evaporating temperature range is a critical factor. Semi-hermetic units, like the Bitzer Semi-Hermetic Open-type Condensing Unit (-45~5℃), are designed for a wide range, accommodating both medium-temperature (e.g., cold rooms) and low-temperature applications (e.g., freezers, blast chillers, cryogenic storage). Compressor selection, refrigerant choice, and additional features like liquid injection or desuperheaters are tailored based on this specific temperature requirement to ensure optimal performance and prevent compressor damage.

Q4: What certifications should I look for when purchasing a semi-hermetic condensing unit?

A4: Look for units that comply with international quality and safety standards. Key certifications include ISO 9001 (for quality management systems), CE marking (for European safety standards), and specific performance ratings from organizations like ASHRAE or AHRI. These certifications ensure the unit meets rigorous design, manufacturing, and performance criteria, offering assurance of reliability and safety.

Conclusion: Powering Industrial Excellence with Advanced Refrigeration

The continuous evolution of industrial processes demands refrigeration solutions that are not only powerful and efficient but also adaptable and sustainable. The semi hermetic condensing unit, exemplified by the Bitzer Semi-Hermetic Open-type Condensing Unit, stands as a testament to this demand, offering an unparalleled blend of performance, reliability, and long-term value. Its design, allowing for in-field maintenance and component replacement, positions it as a superior choice for critical industrial applications where uninterrupted operation and optimized life-cycle costs are paramount. From the meticulous manufacturing processes ensuring precision and durability, to the integration of advanced technical parameters for enhanced efficiency, these units are engineered to meet the most demanding industrial refrigeration challenges. Our expertise, spanning over two decades in delivering tailored solutions across diverse sectors, ensures that each client receives a system perfectly aligned with their operational needs and environmental objectives. Choosing an advanced semi-hermetic solution is not merely an investment in cooling capacity; it is a strategic decision for operational resilience, energy savings, and a sustainable future for your enterprise.

Authoritative References

- International Institute of Refrigeration (IIR) - Latest trends in industrial refrigeration technologies.

- ASHRAE Handbook - Refrigeration (2022).

- Bitzer SE Official Publications - Compressor technology and application guidelines.

- ISO 9001:2015 - Quality management systems standards.

- European Union F-Gas Regulation (EU) No 517/2014 - Refrigerant phase-down schedules.