Efficient Water Chiller Cooling Systems for Industrial Applications and Advanced Factory Solutions

Understanding Water Chiller Cooling Systems in Factories

In today's industrial landscape, maintaining optimal temperatures is crucial for efficient operations. Water chiller cooling systems have emerged as essential components in various manufacturing and processing environments. These systems are designed to remove heat from a process, equipment, or space, ensuring that operations run smoothly and products maintain their quality.

What is a Water Chiller?

A water chiller is a type of cooling system that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. The cooled liquid, usually water or a water-glycol mixture, is then circulated through pipes to absorb heat from industrial processes before it returns to the chiller to be re-cooled. This process is particularly important in factories where machinery generates considerable heat or in processes that require strict temperature control.

How Water Chillers Work

Water chiller systems typically consist of several key components 1. Compressor This component compresses the refrigerant gas and raises its temperature and pressure. 2. Condenser The hot gas moves into the condenser, where it releases heat and condenses into a liquid. 3. Expansion Valve The high-pressure liquid refrigerant then passes through an expansion valve, where it experiences a drop in pressure, causing it to cool significantly. 4. Evaporator Finally, the cold refrigerant enters the evaporator, absorbing heat from the water flowing through the system. This process cools the water, which is then pumped out to various parts of the factory.

Benefits of Water Chiller Systems

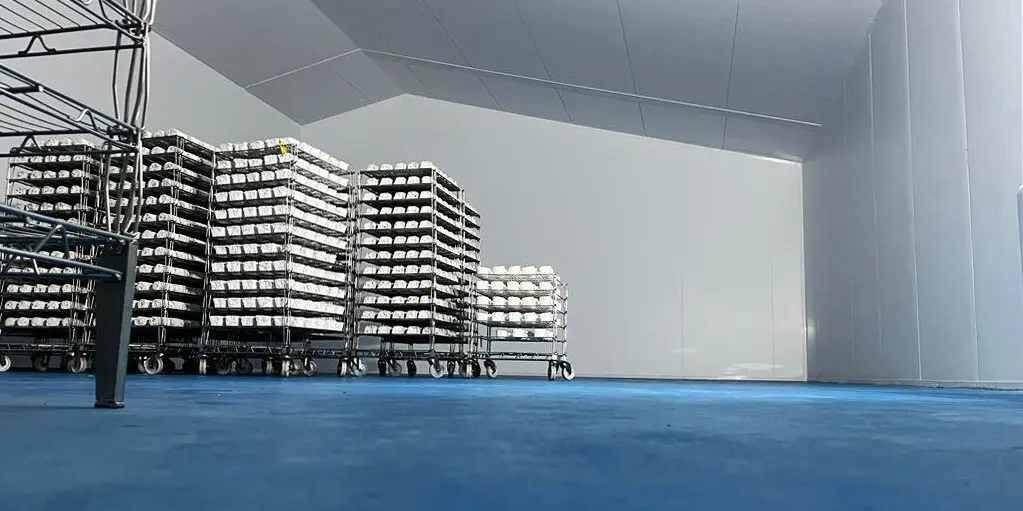

water chiller cooling system factory

1. Energy Efficiency Modern water chillers are designed to be highly energy-efficient, reducing operational costs for factories. With the continual rise in energy prices, businesses are keen to invest in technologies that can lower their bills and carbon footprint.

2. Temperature Control Maintaining precise temperatures is critical in many manufacturing processes. Water chillers provide reliable cooling that supports optimal operating conditions, preventing overheating and associated product defects.

3. Versatility Water chillers can be used in a range of applications, from cooling machinery and equipment to supporting HVAC systems in larger facilities. Their adaptability makes them a favorite among factory operators.

4. Improved Equipment Longevity By preventing overheating, water chillers can extend the life of expensive industrial equipment. This not only minimizes replacement costs but also keeps production lines running without interruptions.

Conclusion

Water chiller cooling systems play a vital role in the efficiency and effectiveness of factory operations. As industries continue to prioritize energy efficiency and optimal performance, the reliance on these systems is expected to grow. Choosing the right chiller involves considering factors such as the specific cooling needs, energy consumption, and maintenance requirements. With advancements in technology, modern water chillers offer innovative solutions tailored to meet the demands of today’s manufacturing environments.

Ultimately, investing in a robust water chiller cooling system is not merely a cost—it's a commitment to operational excellence, sustainability, and product quality. As factories continue to evolve, the role of effective cooling systems will remain indispensable.