How Does A Commercial Ice Machine Work? ICE MACHINE

Since commercial ice machines have advanced, the latest models feature digital technology, helping users keep their machines working optimally. Despite these advancements, the basic functions of commercial machines remain unchanged.

A commercial ice machine can produce a lot of ice in a short period. This guide will further discuss how.

Flake Ice Machine

Components of Ice Making

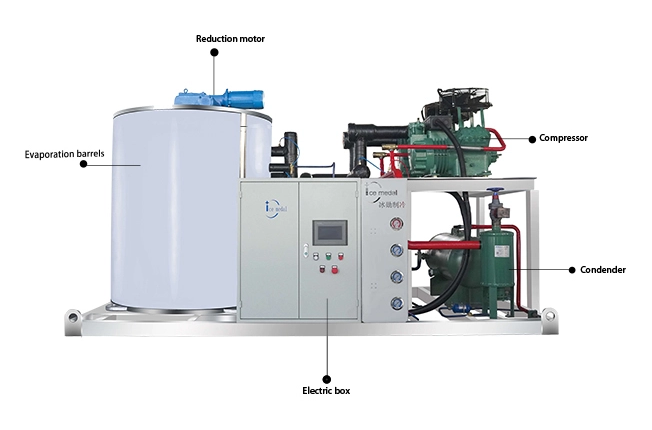

Modern refrigeration systems in commercial ice makers comprise four components — the evaporator, expansion valve, condenser, and compressor. The refrigerant flows through each component to change the temperature during the process.

The machine won’t perform according to its specifications if any component fails. In most cases, industrial ice machines fail to produce sufficient ice to meet business demands. In some instances, the machine may stop making any ice at all. So caring for your machine’s components by following routine maintenance and proper cleaning schedule is essential.

How Does the Ice Machine Refrigerant Work?

The refrigerant in a commercial ice maker is used to freeze water. It cools and heats throughout the ice-making journey. Moreover, its physical state changes from liquid to vapor and back to liquid during heating and cooling cycles.

By the time it reaches the evaporator, the refrigerant is in the form of a low-temperature, low-pressure liquid. During this step, heat in the water moves towards the cold refrigerant, lowering the water’s temperature to the freezing point.

Every ice machine consists of refrigerant gas pushed through the system by the compressor. Once the ice machine turns on, the compressor increases refrigerant pressure, affecting the temperature.

As the refrigerant passes through narrow copper tubes, it loses heat to condense. While traveling through an expansion valve, the fluid evaporates and forms gas. This process generates energy from copper pipes in the form of heat. Any air surrounding the refrigerant removes heat from the pipes and evaporator.

Ice Machine Compressor

The refrigerant is heated and pressurized in the ice machine compressor. This step helps prepare the refrigerant for expansion later. Once the fluid is vaporized, it converts to high-pressure liquid before passing through the expansion valve. In its pressurized state, the refrigerant is hot vapor, passing through the condenser to cool. The condenser helps water freeze in the evaporator.

Ice Machine Condenser

The ice machine condenser changes the state of the refrigerant from vapor to liquid by cooling it. It features a series of metal tubes in the ice machine. These metal coils remove heat from the refrigerant while cooling it effectively.

The cooling process in a commercial ice maker is complete as it forces running water (water-cooled machines) or air (air-cooled machines) over hot coils. The heat is transferred into the water or air and ejected out. The refrigerant’s temperature eventually lowers, changing into a high-pressure liquid from a high-pressure vapor.

Ice Machine Expansion Valve

The thermostatic expansion valve removes the refrigerant’s pressure through rapid expansion. The process through which ice makers work to produce ice is called adiabatic cooling. As a high-pressure substance expands, pressure changes quickly cool the substance.

For the same reason, the pressurized air used to clean a keyboard gets cod as you hold the trigger. The ejecting air releases pressure in the can, cooling the liquid in the can.

Rapid expansion in ice machines transforms the refrigerant from high-pressure and high-temperature liquid to low-temperature, low-pressure liquid.

Ice Machine Evaporator

Water in the evaporator freezes to produce ice. Once low-pressure water reaches the evaporator, its heat moves into the refrigerant through the evaporator plate. Water flowing over the evaporator begins to cool and reaches the freezing point, forming ice cubes.

Once an ice cube is frozen, the machine begins a harvest cycle to collect more ice for use. Commercial ice makers either use hot gas or water at room temperature to warm the evaporator. This causes used ice to melt in store in the ice bin.

Process of Ice Making

The ice tray in a commercial ice machine is connected to a series of coiled pipes that exchange heat. This ice tray ice chilled by the refrigeration process. Water in the ice maker is pumped from a collection sump which pours it slowly over the ice tray. As a result, water gradually freezes in layers, forming clear ice. Freezing all the water once will make it cloudy.

Next, the ice machine triggers a solenoid valve connected to the pipes exchanging heat. As this valve activates, it changes the refrigerant’s direction. Then the gas is forced in into a bypass tube by the compressor. Without being condensed, the gas moves back to the evaporator and causes the ice tray and the heat exchanging pipes to heat up rapidly. This loosens the newly formed ice.

Ice trays are generally slanted in modern ice machines, so as the ice heats up, it slides out easily. Other ice makers are equipped with a cylindrical piston that helps knock out the ice from the tray.

What Makes Ice Cloudy and Clear?

Ice produced by a commercial ice machine in an ice cube tray is mostly cloudy or white in the center. That’s because as water in a tray is left to freeze, it will freeze from the outside in. The purest, cleanest water freezes first, while the minerals, impurities, and air bubbles are pushed towards the cube’s center. That’s what makes the ice cloudy.

Commercial ice makers circulate water over a cold plate/grid. This freezes the ice from inside out or a layer at a time. While the purest, cleanest water freezes, impurities, air bubbles, and minerals move along continually. This means that the clearest ice cubes are made from the purest water.