Whether it’s a sweltering summer day or your employees and guests want fresh, crisp drinking water, you can quickly elevate your workplace water supply with clean ice. But, have you ever wondered how that ice is made?

Read on to learn more about the ins and outs of a commercial ice maker, along with the benefits they offer and how teams can determine the right ice machine for their unique business needs.

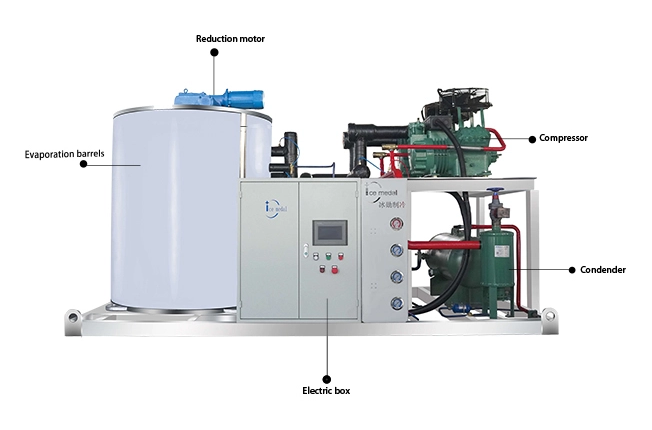

Flake Ice Machine

The Inner Workings of an Ice Machine

Most of us are aware that ice is made up of water. When cooled at a certain temperature, fresh ice is formed and kept at the same temperature to preserve it for later use. But, there’s a little more to the story than meets the eye, and delving into the gritty details of ice production is key to finding the perfect ice machine for your workplace.

A modern ice maker is composed of four primary components: the compressor, condenser, expansion valve, and evaporator. Each part of the unit is filled with a refrigerant, circulating and changing temperatures as it flows through the system. Here’s a closer look at these elements:

The Compressor

When it comes to ice-making, the compressor is a crucial component. By pressurizing and heating the refrigerant, this step prepares the refrigerant for rapid expansion, which occurs a little later in the process.

The Condenser

Condensers are the metal tubes that cool the refrigerant, transforming it from a vapor into a liquid. The refrigerant will flow through these coils to draw heat away and effectively cool the water. Finally, depending on whether you have an air-cooled or water-cooled unit, heat is expelled from the machine using air or flowing water. This lowers the refrigerant’s temperature, transitioning it from a high-pressure vapor to a high-pressure liquid.

The Expansion Valve

The thermostatic expansion valve is essential for rapidly expanding and releasing pressure from the refrigerant. This process, called adiabatic cooling, results in a significant temperature drop in the refrigerant. You can think of this like when you release pressurized air from a can and it quickly cools — where a pressure shift happens that causes the liquid inside to cool as it exits the can. Rapid expansion is what turns a high-pressure liquid refrigerant into a low-pressure, low-temperature liquid during ice production.

The Evaporator

Finally, in the ice maker’s evaporator, a water drop freezes into a solid ice cube. This happens due to the low-pressure liquid reaching the evaporator, where heat from the water transfers into the refrigerant. As water flows over the evaporator, it gradually cools until it reaches the freezing point and forms ice cubes.

Once the entire cube has frozen, your unit initiates the harvest cycle. This involves warming the evaporator using either hot gas or room-temperature water, melting the ice, and releasing it into your commercial ice bin. This way, it’s ready for use whenever you or your employees need an ice cold glass of drinking water at work.

Discover the Commercial Ice-Making Process

While an ice maker is generally made up of the same four main components, there’s a slight difference in how a commercial ice maker will operate depending on the type of ice you want to offer. So, what does the ice maker cycle look like for each?

Discover the following steps involved in ice production for three main ice types:

1. Crescent Ice

This half-mooned shaped ice is ideal for liquid displacement in beverages and allows a glass to hold more ice — all while making drinks look fuller. Crescent ice also limits splashing when added to beverages and is less susceptible to packing together or “bridging” while being stored. This ice type is commonly used in ice bagging, soft drinks, and mixed drinks.

Ice maker steps to produce crescent ice:

- Ice formation begins as water cascades across a mold or tray, which is then chilled to create the distinct crescent ice shape.

- After freezing is completed, the mold is then quickly heated to release the ice from the mold for storage or use.

Note: Some crescent systems freeze ice on both sides of the evaporator, which allows a unit to produce more ice in fewer cycles.

2. Nugget Ice

Also known as cubelet ice, chewblet ice, or Pellet ice, this ice type is highly popular for its soft texture that retains liquid. Because nugget ice is soft and chewable, it’s perfect for people who enjoy chewing ice, but don’t want to risk the chance of chipping a tooth. It’s preferred by bars and restaurants, like Sonic and Chick-fil-A because the small, semi-soft, nubby-textured chunks of ice are good at absorbing flavor and amplifying drinks.

Ice maker steps to produce nugget ice:

- First, water is forced through either an auger or a coil.

- While water flows through the auger, it gets chilled. This results in the formation of ice.

- Finally, the end of the auger pushes the frozen coil across a cutting surface, which cuts the ice into smaller pieces.

3. Tulip Ice

Named for its rounded, cupped-shape, tulip ice is another great choice for chilling drinks. Where softer nugget ice tends to absorb the liquid for drinks and melt faster, tulip ice is more solid and takes longer to melt — so it’s less likely to dilute drinks. The rounded shape of tulip ice also provides more surface area to help cool drinks faster.

Ice maker steps to produce tulip ice:

- This process begins by submerging evaporator “fingers” in a chilled water bath, where ice forms on them.

- This cold water bath is then dumped and the fingers begin to warm.

- Lastly, the ice melts off of the fingers and falls into a collection bin for storage and use.

With a better understanding of commercial ice machines, their elements, and the production and refrigeration cycle, you can appreciate the intricacy of the process. Regardless of the ice type you’re after, a workplace ice maker continues the cycles above until your ice storage bin or tray is fully stocked — ensuring you have an ample supply for your employees, guests, and customers on demand.

The Value of High-Quality Ice Maker Maintenance

It’s important to note that if any of the essential components or processes of your unit malfunction, you can struggle to produce enough clean ice to satisfy these individuals’ needs. This underscores the importance of regular ice maker repair and maintenance to make sure your machine is always in great working condition.

The Benefits of a Workplace Ice Machine

With a premium commercial ice maker, your business is set to enjoy a host of workplace benefits including:

- Enhanced hydration as fresh ice encourages employees to drink more water. This promotes better hydration throughout the workday.

- Increased cognitive function, which ultimately leads to improved focus and productivity among team members.

- Greater employee satisfaction from workers who feel their comfort and well-being is being taken into account.

- Improved workplace culture, leading to higher engagement levels.

- Reduced absenteeism in a generally healthier workforce, decreasing health-related issues at work.