Superior Flake Ice Machines Designed for Optimal Freshness and Quality in Seafood Preservation

High-Quality Flake Ice Machine for Fish Enhancing Freshness and Quality

In the seafood industry, the preservation and quality of fish are paramount. One of the key components in maintaining the freshness of seafood is the use of ice, and specifically, flake ice. Flake ice machines have become indispensable for fishmongers, restaurants, and seafood processing facilities due to their efficiency and effectiveness in keeping fish at optimal temperatures. This article explores the significance of high-quality flake ice machines for fish, shedding light on their benefits, features, and the criteria for selecting the right machine.

Why Flake Ice?

Flake ice consists of small, thin ice flakes that cover the surface of fish, creating a uniform cooling effect. Unlike chunks of ice, flake ice has a larger surface area that enables faster heat transfer, ensuring that fish are kept at a safe temperature to prevent spoilage. This type of ice not only chills fish quickly but also prolongs their freshness and quality, making it a preferred choice for the seafood industry.

Benefits of High-Quality Flake Ice Machines

1. Optimal Cooling Performance High-quality flake ice machines provide a consistent and uniform production of ice flakes. This ensures that the fish are effectively cooled, allowing for prolonged preservation. The ice's ability to minimize temperature fluctuations is crucial in maintaining the quality of seafood, especially during transportation and storage.

2. Improved Fish Quality Freshness is key to high-quality fish. Flake ice protects the fish from dehydration and freezer burn, which can compromise texture and taste. When fish are stored on flake ice, they retain their natural moisture, leading to higher quality products for consumers.

3. Efficiency and Production Speed Advanced flake ice machines are designed for high output, producing a significant quantity of ice quickly. This is particularly important for businesses that require large volumes of ice for their operations, such as fish markets and processing facilities. Reduced downtime and increased efficiency help in meeting demand without compromising on quality.

4. Energy Efficiency Modern machines are equipped with energy-efficient technology, reducing operational costs while still maximizing output. An energy-efficient flake ice machine not only lowers electric bills but also supports environmentally friendly practices in the seafood industry.

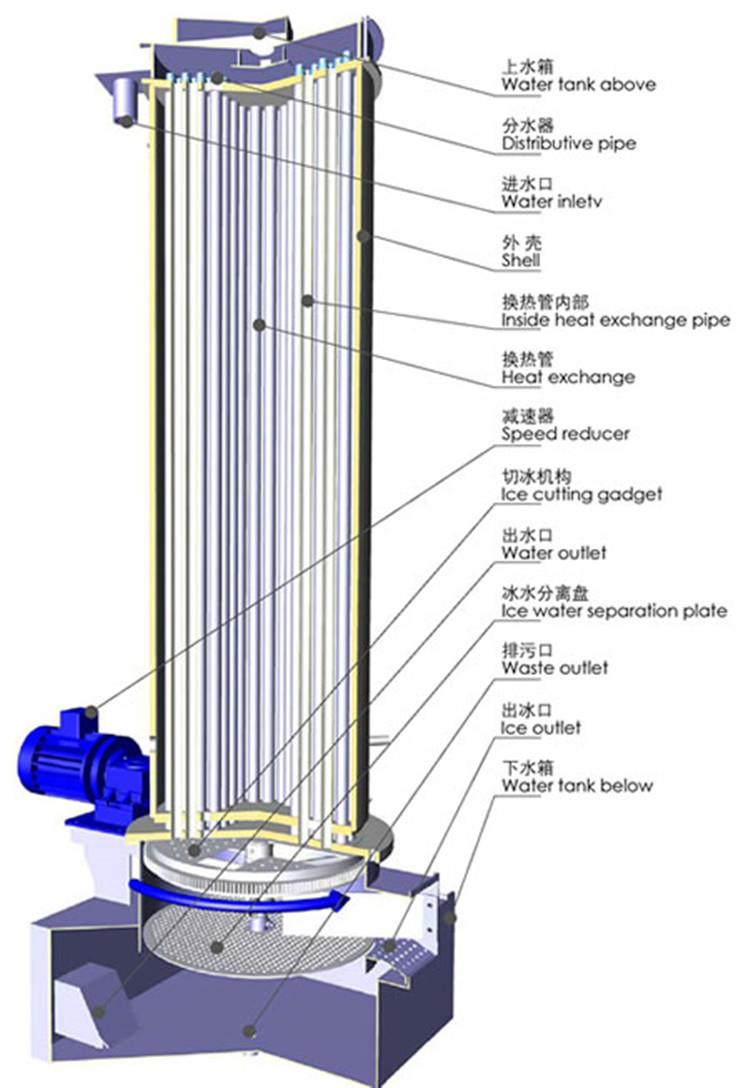

high quality flake ice machine for fish

5. Durability and Reliability Investing in a high-quality flake ice machine means investing in durability. These machines are built to withstand rigorous daily use and can operate effectively in various environments, whether in a busy kitchen or a commercial fishing operation.

Choosing the Right Flake Ice Machine

When selecting a flake ice machine, several factors should be considered

- Production Capacity Determine the amount of ice your business requires daily and select a machine that meets or exceeds that capacity.

- Space Constraints Assess the space available for the machine. Compact models are suitable for smaller operations, while larger businesses may require high-capacity models.

- Ease of Use and Maintenance Look for machines that offer user-friendly controls and require minimal maintenance. Features such as automated cleaning systems are advantageous for keeping the machine in optimal condition.

- Manufacturer Reputation Choosing a reputable manufacturer is essential for ensuring quality and reliability. Research customer reviews and after-sales support to ensure you are making an informed decision.

In conclusion, high-quality flake ice machines play a vital role in preserving the freshness and quality of fish in the seafood industry. By providing optimal cooling, improving the quality of fish, and offering efficient, energy-saving operation, these machines are essential tools for any business focused on delivering the best seafood products to consumers. Investing in a reliable flake ice machine will ultimately lead to enhanced customer satisfaction and business success in the competitive seafood market.