THE ICE PRODUCTION PROCESS FOR COMMERCIAL ICE MACHINES

Commercial ice machines are an essential piece of equipment to have in any food service or hospitality business that requires a constant supply of ice. These machines work by producing ice in various shapes and sizes, ranging from cubed to crushed, to meet the diverse needs of businesses. But how exactly do these machines produce ice? Let's take a closer look at the ice production process.

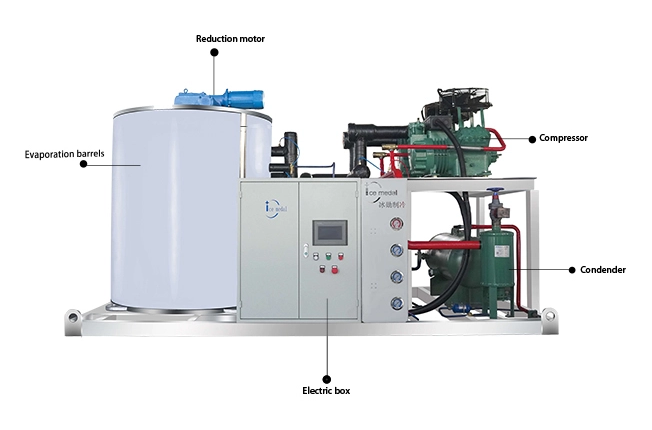

Flake Ice Machine

STEP 1: WATER SUPPLY

The first step in the ice production process is to supply water to the ice machine. The water supply is connected to the machine through a valve, and the water enters the machine through a water inlet. The water then flows into a reservoir, which is where the freezing process begins.

STEP 2: FREEZING PROCESS

Once the water is in the reservoir, the freezing process begins. A refrigeration unit in the ice machine cools the water to a temperature of around 32°F (0°C), which causes the water to freeze. As the water freezes, it forms a layer of ice on the surface of the water.

STEP 3: HARVESTING PROCESS

After the ice has formed, the harvesting process begins. A harvesting mechanism, such as an auger or blade, breaks up the layer of ice and pushes it onto a grid or mold. The grid or mold then shapes the ice into the desired shape and size.

STEP 4: STORAGE PROCESS

Finally, the ice is stored in a bin until it is ready to be used. The bin is insulated to keep the ice frozen and prevent it from melting. A sensor in the bin monitors the level of ice and signals the ice machine to produce more ice when the level falls below a certain point.

THE PROCESS EXPLAINED

The ice production process for commercial ice machines involves four main steps: water supply, freezing process, harvesting process, and storage process. Each step is essential in producing a constant supply of ice for businesses. By understanding the ice production process, businesses can choose the right ice machine for their needs and ensure they have a reliable source of ice for their customers.