Top Manufacturers of 0.5 HP Water Chillers for Efficient Cooling Solutions and Industrial Applications

Understanding 1/2 HP Water Chiller Factories

Water chillers play an essential role in various industrial applications, providing cooling solutions for manufacturing processes, HVAC systems, and more. Among the different types of chillers available, the 1/2 HP (horsepower) water chiller is becoming increasingly popular, especially for small to medium-sized facilities. In this article, we will explore the characteristics, benefits, and manufacturing aspects of 1/2 HP water chillers.

What is a 1/2 HP Water Chiller?

A 1/2 HP water chiller is a compact cooling unit that utilizes a refrigeration cycle to reduce the temperature of water. The term 1/2 HP refers to the power rating of the chiller's compressor, indicating that it can deliver a moderate cooling capacity suitable for low to mid-range cooling requirements. These chillers are often used in applications where space is limited, making them an ideal choice for small workshops, laboratories, and even residential settings.

Benefits of 1/2 HP Water Chillers

1. Energy Efficiency One of the key advantages of a 1/2 HP water chiller is its energy efficiency. With lower horsepower requirements, these chillers consume less electricity compared to larger units, leading to reduced operating costs over time.

2. Compact Size The small footprint of 1/2 HP chillers allows them to be easily installed in areas with limited space. This makes them a practical option for businesses that may not have the luxury of abundant square footage for cooling equipment.

4. Versatile Applications These chillers can be utilized in various settings, including aquariums, computer server rooms, beverage cooling, and medical laboratories, proving their versatility and adaptability to different industrial needs.

5. User-Friendly Most 1/2 HP water chillers are designed to be user-friendly, featuring straightforward controls and minimal maintenance requirements. This accessibility can save time and resources for operators.

1/2 hp water chiller factories

Manufacturing of 1/2 HP Water Chillers

The manufacturing of 1/2 HP water chillers involves several stages, from design to final assembly. Factories specializing in these chillers typically focus on high-quality components to ensure reliability and performance. Some key points in the manufacturing process include

- Design and Engineering The design team works on creating efficient cooling systems that optimize airflow, refrigerant pathways, and heat exchange areas. Advanced simulation software may be used to test various configurations before production.

- Component Sourcing Manufacturers carefully select components such as compressors, evaporators, condensers, and fans, opting for durable materials that can withstand constant usage.

- Assembly Line Production The assembly of these chillers takes place in a controlled environment, where skilled technicians ensure each unit is built to specification. Quality control checks are performed throughout the process to identify and rectify any issues early on.

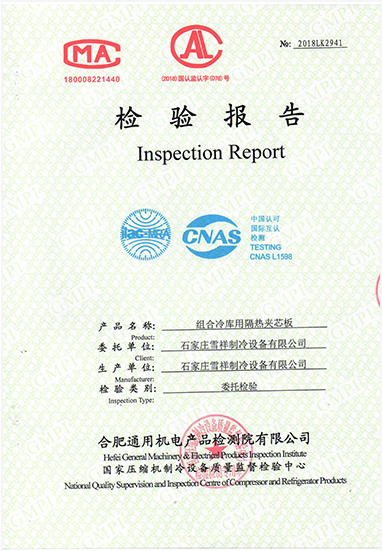

- Testing Before leaving the factory, each 1/2 HP water chiller undergoes rigorous testing for cooling performance, energy efficiency, and safety measures. This step is crucial to ensuring that the chillers meet industry standards and customer expectations.

- Customer Support Many manufacturers provide after-sales support, including installation guidance and maintenance services. This ongoing relationship with customers helps ensure the longevity and optimal performance of their water chillers.

Conclusion

In conclusion, 1/2 HP water chillers are a valuable addition to the cooling solutions available for small to medium-sized applications. With their energy efficiency, compact design, and cost-effectiveness, they have carved a niche in various industries. Understanding the manufacturing process behind these chillers helps underscore their importance and the care taken to produce reliable, efficient cooling systems. As technology advances, we can expect further improvements in the design and functionality of water chillers, making them even more beneficial for industrial and commercial use.