Jun . 28, 2024 16:00

Back to list

Top Monoblock AC Unit Manufacturers Exploring Leading Factories for Efficient Cooling Solutions

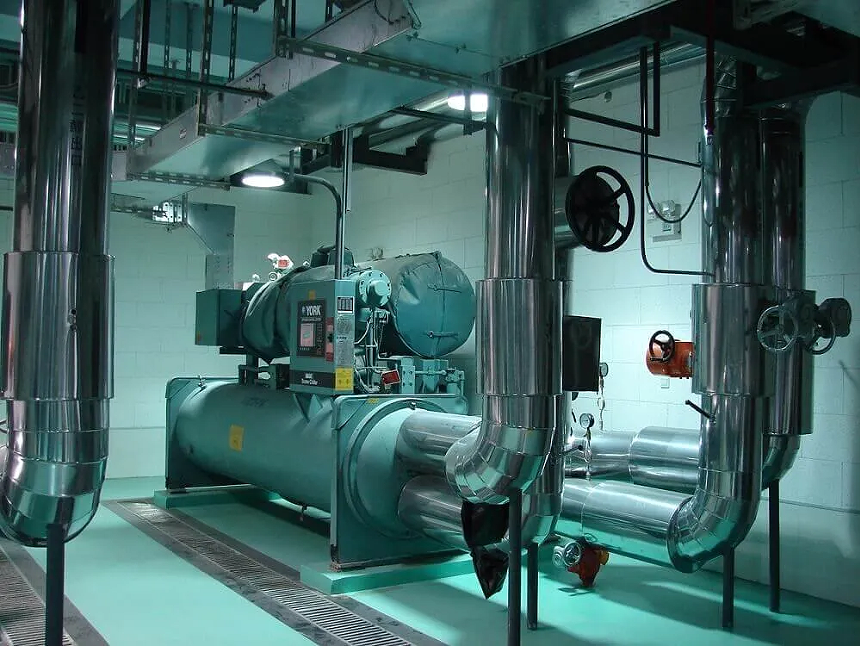

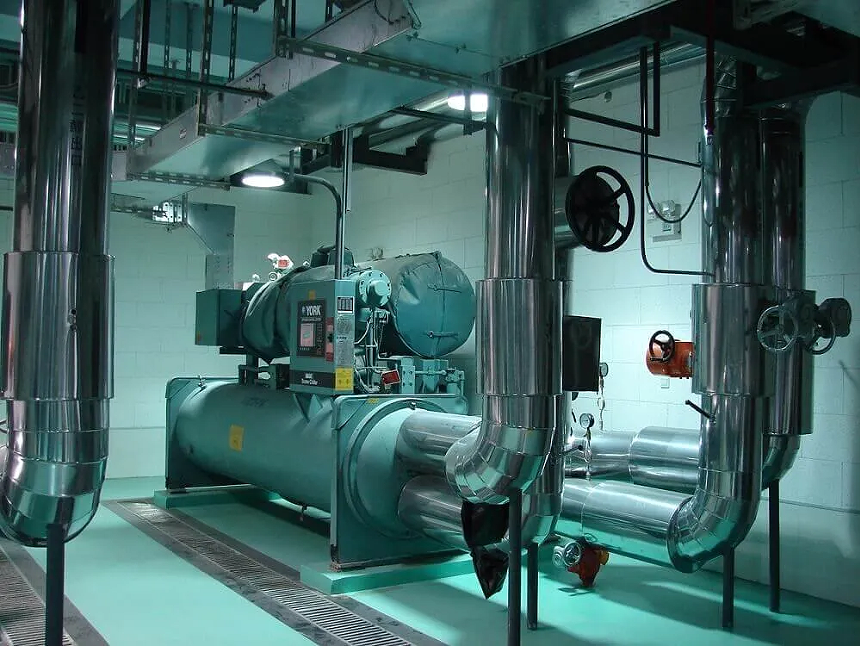

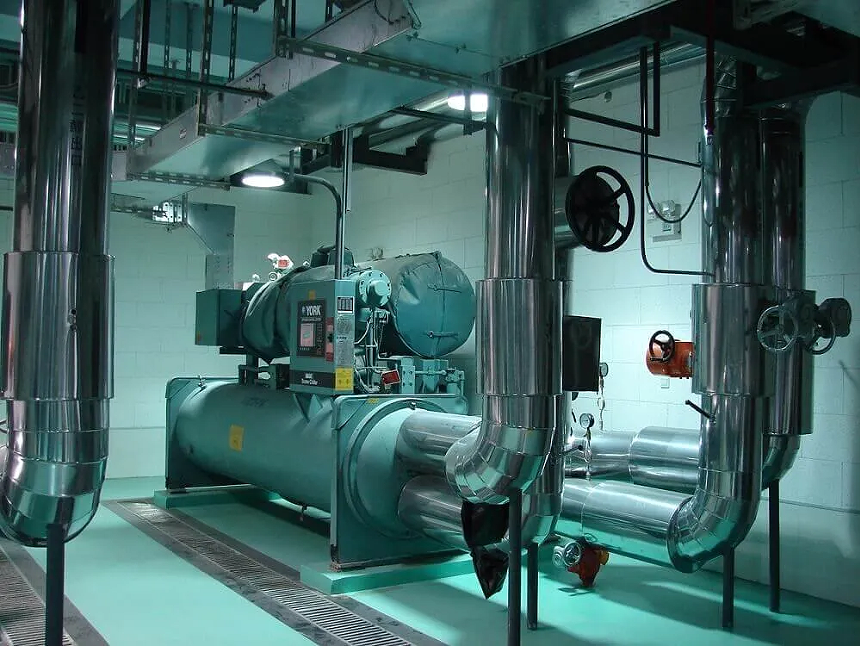

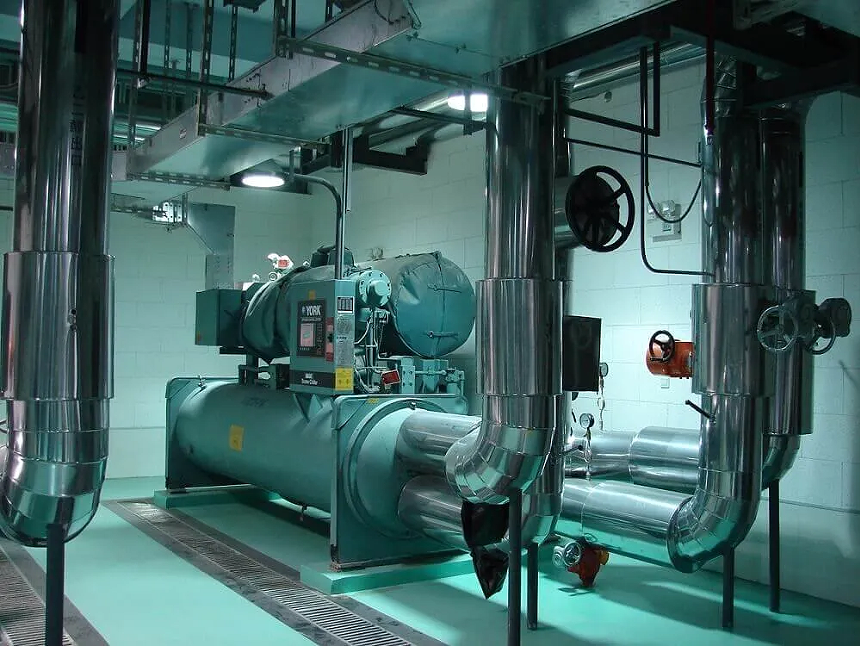

Monoblock AC Unit Factories The Heart of Modern Cooling Technology

In the realm of modern technology and climate control, monoblock AC units have carved a niche for themselves due to their compact design and efficient performance. These units, also known as window air conditioners or all-in-one cooling systems, are manufactured in specialized factories that blend precision engineering with innovative design. This article delves into the world of monoblock AC unit factories, exploring their operations, manufacturing processes, and the impact they have on the global HVAC industry.

Monoblock AC unit factories are typically large-scale industrial facilities equipped with cutting-edge machinery and skilled technicians. They operate on a comprehensive production line model, where each stage is meticulously managed to ensure quality and consistency. From the initial design phase to the final assembly, every step is crucial in crafting these units.

The manufacturing process begins with the fabrication of individual components, including the compressor, evaporator, condenser, and fan motors. Each component is crafted with precision to withstand the rigors of daily use and deliver optimal cooling performance. High-strength metals and durable plastics are utilized to ensure durability and resistance to environmental factors.

Once the components are fabricated, they undergo rigorous quality checks before being assembled together. This is where the 'monoblock' aspect comes into play, as all components are integrated into a single, compact unit. The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss

The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss monoblock ac unit factories.

Monoblock AC unit factories also invest heavily in research and development. With the increasing demand for energy-efficient and eco-friendly solutions, engineers work tirelessly to improve the units' energy ratings and reduce their carbon footprint. Advanced technologies like inverter compressors and smart cooling systems are incorporated to enhance efficiency and user convenience.

These factories not only manufacture the units but also provide after-sales services, including installation guidance, maintenance, and repair. A strong network of distributors and service centers ensures customer satisfaction and extends the life of the products.

Monoblock AC unit factories contribute significantly to the global HVAC industry by meeting the diverse cooling needs of residential, commercial, and industrial sectors. Their products cater to a wide range of environments, from small apartments to large office spaces, providing reliable and efficient cooling solutions.

In conclusion, monoblock AC unit factories are the backbone of the air conditioning industry, combining advanced technology with efficient manufacturing processes. They continuously strive for innovation, driving the sector towards more sustainable and efficient cooling options. As the world becomes increasingly conscious of energy consumption, these factories will play a pivotal role in shaping the future of climate control technology.

monoblock ac unit factories.

Monoblock AC unit factories also invest heavily in research and development. With the increasing demand for energy-efficient and eco-friendly solutions, engineers work tirelessly to improve the units' energy ratings and reduce their carbon footprint. Advanced technologies like inverter compressors and smart cooling systems are incorporated to enhance efficiency and user convenience.

These factories not only manufacture the units but also provide after-sales services, including installation guidance, maintenance, and repair. A strong network of distributors and service centers ensures customer satisfaction and extends the life of the products.

Monoblock AC unit factories contribute significantly to the global HVAC industry by meeting the diverse cooling needs of residential, commercial, and industrial sectors. Their products cater to a wide range of environments, from small apartments to large office spaces, providing reliable and efficient cooling solutions.

In conclusion, monoblock AC unit factories are the backbone of the air conditioning industry, combining advanced technology with efficient manufacturing processes. They continuously strive for innovation, driving the sector towards more sustainable and efficient cooling options. As the world becomes increasingly conscious of energy consumption, these factories will play a pivotal role in shaping the future of climate control technology.

The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss

The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss The integration process requires great attention to detail, ensuring seamless connections and minimal energy loss monoblock ac unit factories.

Monoblock AC unit factories also invest heavily in research and development. With the increasing demand for energy-efficient and eco-friendly solutions, engineers work tirelessly to improve the units' energy ratings and reduce their carbon footprint. Advanced technologies like inverter compressors and smart cooling systems are incorporated to enhance efficiency and user convenience.

These factories not only manufacture the units but also provide after-sales services, including installation guidance, maintenance, and repair. A strong network of distributors and service centers ensures customer satisfaction and extends the life of the products.

Monoblock AC unit factories contribute significantly to the global HVAC industry by meeting the diverse cooling needs of residential, commercial, and industrial sectors. Their products cater to a wide range of environments, from small apartments to large office spaces, providing reliable and efficient cooling solutions.

In conclusion, monoblock AC unit factories are the backbone of the air conditioning industry, combining advanced technology with efficient manufacturing processes. They continuously strive for innovation, driving the sector towards more sustainable and efficient cooling options. As the world becomes increasingly conscious of energy consumption, these factories will play a pivotal role in shaping the future of climate control technology.

monoblock ac unit factories.

Monoblock AC unit factories also invest heavily in research and development. With the increasing demand for energy-efficient and eco-friendly solutions, engineers work tirelessly to improve the units' energy ratings and reduce their carbon footprint. Advanced technologies like inverter compressors and smart cooling systems are incorporated to enhance efficiency and user convenience.

These factories not only manufacture the units but also provide after-sales services, including installation guidance, maintenance, and repair. A strong network of distributors and service centers ensures customer satisfaction and extends the life of the products.

Monoblock AC unit factories contribute significantly to the global HVAC industry by meeting the diverse cooling needs of residential, commercial, and industrial sectors. Their products cater to a wide range of environments, from small apartments to large office spaces, providing reliable and efficient cooling solutions.

In conclusion, monoblock AC unit factories are the backbone of the air conditioning industry, combining advanced technology with efficient manufacturing processes. They continuously strive for innovation, driving the sector towards more sustainable and efficient cooling options. As the world becomes increasingly conscious of energy consumption, these factories will play a pivotal role in shaping the future of climate control technology. Related PRODUCTS

Copyright © 2025 Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy