Working principle of ice machine ICE MACHINE

What is the working principle of ice machine? It is estimated that everyone is unfamiliar with this problem. This article will explain the working principle and workflow of ice machine in detail with the schematic diagram.

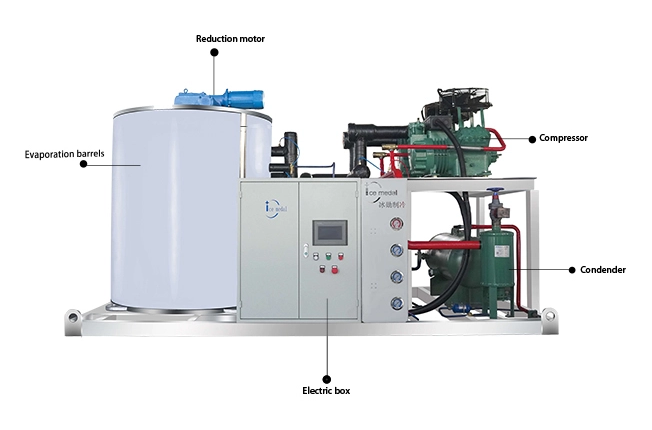

Flake Ice Machine

Ice maker is a kind of refrigeration mechanical equipment that cools water through refrigerant of refrigeration system to generate ice. As shown in Figure 1, it is widely used in aquatic products, food, dairy products, medicine, chemistry, vegetable preservation and other industries. With the development of society and the continuous improvement of people’s production level, the ice industry is becoming wider and wider, and the social demand for ice machines is also growing.

Ⅰ. Brief introduction of working principle

The refrigeration principle of ice maker is shown in the following figure. The refrigerant is compressed by compressor into high-temperature and high-pressure gas, cooled by condenser, liquefied into medium-temperature and high-pressure liquid, throttled by throttling system, then flows to evaporator and evaporates in its pipeline. The refrigerant absorbs the heat of surrounding environment to freeze water, then flows back to compressor through return pipe, and then is compressed and discharged. This cycle makes water into ice until ice cubes reach a certain thickness.

The refrigerant is compressed into high-temperature and high-pressure gas in the compressor and discharged, and then directly enters the evaporator through the heat supply pipe, so that the temperature of the evaporator rises, and then the ice cubes fall off the evaporator under the combined action of the refrigerant and the supplementary water. After completing the ice-making process once, continue to repeat until the ice cubes in the refrigerator are piled up completely, and the ice-making process is suspended. After taking out the ice cubes, the ice maker continues the above cycle.

1. Ice making process

After the machine is powered on, put the function switch in the “Ice Making 20″ state. At this time, the indicator light is on, and the water pump and the drainage solenoid valve are powered on for several seconds (the specific time can be set) to drain the remaining water in the water tank, thus ensuring that the water used for ice making is fresh and clean. During drainage, the hot gas valve is also energized. At the same time, the electronic control board detects whether the ice cubes in the refrigerator are full. If the ice is not full, start the compressor, start the condenser cooling fan at the same time, close the water pump and drain valve, and open the water inlet solenoid valve to enter the ice-making state.

During the whole process of ice making and deicing, the compressor always keeps running, the hot gas valve is closed after the compressor is started for several seconds, the water pump is started after the compressor precools the ice chamber (evaporator) for several seconds, and the water inlet valve is closed when the water level detector contacts the water in the sink for several seconds (when the water level detector contacts with the water, the water level indicator of the controller lights up), or after several minutes of continuous water intake. Under the action of water pump and water separator, water flows evenly through each compartment of the freezing chamber. With the formation of ice cubes, the water level drops and the water level indicator goes out. At this time, water will be replenished once until the water level detector comes into contact with water for several seconds, so as to ensure that there is enough water to make ice.

In the process of ice making, the electronic control board will continuously detect the temperature of the condenser, and once its temperature exceeds its set temperature, it will start the condenser cooling fan to quickly reduce its temperature.

It is worth mentioning that the condenser cooling fan and compressor of some ice machines are controlled by the same contactor, and a pressure switch is connected in series in the main circuit of the condenser cooling fan as the start-stop control of the condensing fan. When the condensing pressure is higher than about 1.7MPa, the condensing fan starts and stops when it is lower than about 1.4Ma:.

2. Deicing process

When the ice thickness detector comes into contact with water flow (not ice) for several seconds, the water pump operates and the drain solenoid valve opens to drain the water in the sink (the drain time can be selected by the drain time switch on the panel). After draining according to the set time, the water inlet solenoid valve, the water drainage solenoid valve and the water pump are closed, and no longer act during the whole deicing process. At the beginning of water drainage, the hot gas valve is opened, and the hot refrigerant vapor flows into the evaporator to heat the ice cubes on the evaporator surface. The ice cubes slide into the ice storage chamber in pieces under the action of gravity, and the box switch is turned on, ending the deicing process, and then entering the ice-making state again.

3. Automatic shutdown when the ice is full

When the ice harvesting process is finished and the refrigerator is full, the indicator light of the box switch goes out at this time, and the ice maker stops working after a few seconds.

-

Transform Operations with Vacuum Freezer MachineNewsMay.14,2025

-

Enhance Business with Cold Room TechnologyNewsMay.14,2025

-

Vacuum Freezer Machine for Modern NeedsNewsMay.09,2025

-

Discover Our Comprehensive Cold Room SolutionsNewsMay.09,2025

-

Cold Room Solutions for Your BusinessNewsMay.08,2025

-

Advanced Vacuum Freezer MachineNewsMay.08,2025