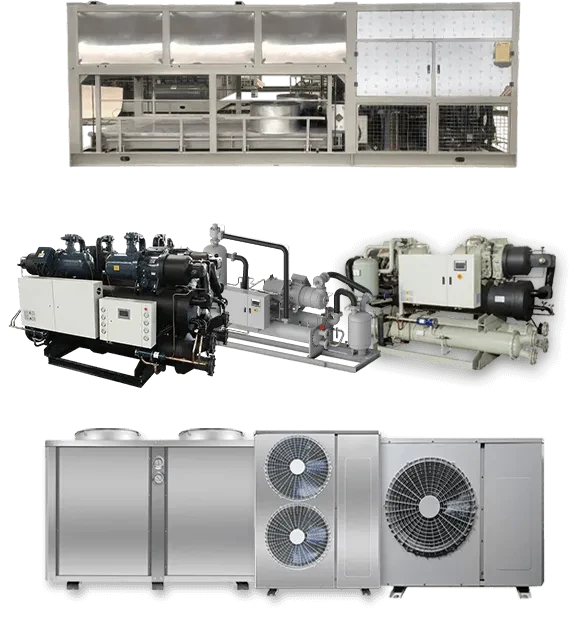

custom air colled chiller

Custom Air-Cooled Chillers Tailoring Solutions for Your Cooling Needs

In today's rapidly evolving industrial landscape, maintaining optimal operating temperatures is crucial for a wide range of applications. Whether in manufacturing, laboratory settings, or commercial spaces, efficient and effective cooling systems are imperative to ensure the reliability and longevity of equipment. Among these solutions, custom air-cooled chillers stand out as a versatile and efficient choice designed to meet the unique requirements of various industries.

Understanding Air-Cooled Chillers

Air-cooled chillers operate by removing heat from a process medium, typically water or glycol, using ambient air to dissipate that heat. Unlike water-cooled systems that require a cooling tower and a consistent water supply, air-cooled chillers rely solely on air for heat exchange. This makes them easier to install and maintain, as they do not necessitate additional components like cooling towers or extensive plumbing, thereby reducing overall system complexity.

The Benefits of Customization

The primary advantage of custom air-cooled chillers is their adaptability. Standard chillers may not sufficiently meet specific operational needs due to varying ambient conditions, load requirements, or space constraints. Custom chillers can be designed with various configurations, including different compressor types, heat exchange capacities, and control systems to accommodate diverse applications.

1. Tailored Capacity Custom chillers can be engineered to deliver exact cooling capacities, allowing businesses to optimize energy usage and avoid oversizing, which can lead to increased operational costs.

custom air colled chiller

3. Compact Design For facilities with limited space, custom chillers can be designed to fit specific spatial constraints while still offering adequate performance. This compact engineering can free up valuable floor space for other essential operations.

4. Specific Application Features For industries requiring unique specifications (like pharmaceuticals, food processing, or data centers), custom chillers can be designed to include features such as improved filtration systems, specialized coatings to withstand corrosive environments, and enhanced monitoring capabilities.

Sustainability Considerations

In an age where environmental consciousness is on the rise, custom air-cooled chillers can also be designed with sustainability in mind. Many modern chillers utilize eco-friendly refrigerants with lower global warming potential. Additionally, by optimizing energy efficiency, businesses can significantly reduce their carbon footprint while maintaining compliance with increasingly stringent regulations.

Maintenance and Support

Investing in a custom air-cooled chiller also comes with the benefit of tailored maintenance plans. Manufacturers often provide comprehensive support, including routine maintenance schedules specific to the chilling system's configuration and operational demands. This proactive approach ensures that the equipment operates at peak efficiency and prolongs its lifespan.

Conclusion

In conclusion, custom air-cooled chillers provide an excellent solution for industries seeking efficient and effective cooling systems tailored to their specific needs. With the ability to combine efficiency, adaptability, and sustainability, these chillers are an investment that can lead to significant long-term savings and operational improvements. As industries continue to evolve, having a cooling solution that can keep pace with changing demands will be paramount. Opting for a custom air-cooled chiller could be the strategic choice that ensures your operations run smoothly and efficiently for years to come.