Industrial Chiller Training Provider for Enhanced Efficiency and Performance Optimization

The Importance of Industrial Chiller Training Selecting a Reliable Supplier

In today's industrial landscape, the efficiency and reliability of cooling systems are vital for optimizing production processes and ensuring the longevity of equipment. Among the key components of these cooling systems are industrial chillers, which play a crucial role in temperature control. However, to maximize the performance of these systems, proper training for operators and maintenance personnel is essential. This is where the selection of a reliable industrial chiller training supplier comes into play.

Understanding Industrial Chillers

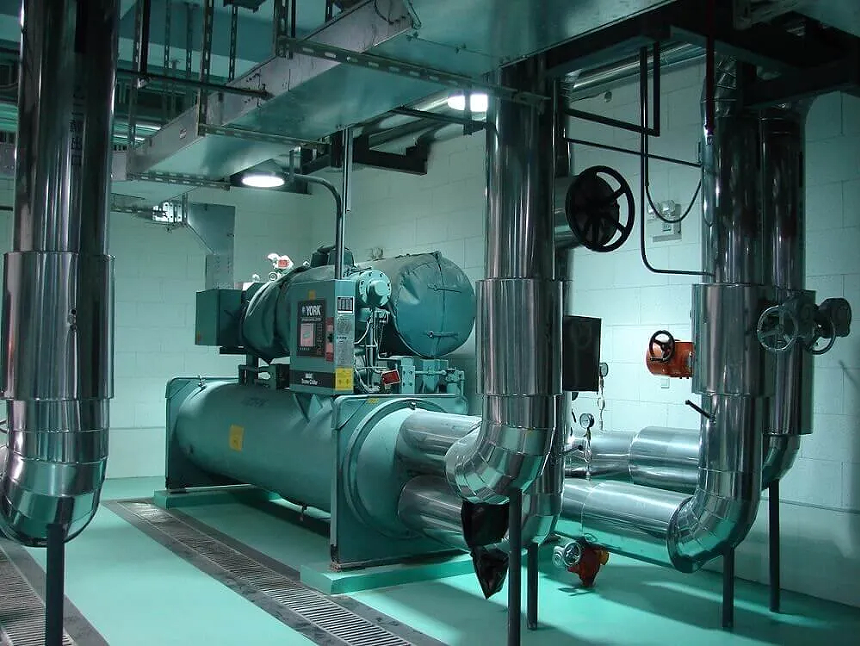

Industrial chillers are refrigeration systems that remove heat from a liquid via a vapor-compression or absorption refrigeration cycle. These chillers are widely used in various sectors, including manufacturing, pharmaceuticals, food processing, and HVAC systems, to maintain specific temperature levels for equipment and processes. Given their significance, improper handling, maintenance, or operation of chillers can lead to inefficiencies, increased energy costs, and even system failures. This underscores the necessity of comprehensive training programs focused on the operation and maintenance of industrial chillers.

The Role of Training

Effective training equips personnel with the knowledge and skills required to operate chillers efficiently. Training programs should cover vital topics such as

1. Understanding Chiller Components Operators need to be familiar with essential components such as compressors, condensers, evaporators, and expansion valves, along with their functions and interconnections.

3. Troubleshooting Techniques Equipped with troubleshooting skills, operators can quickly identify issues such as abnormal noises, temperature fluctuations, or pressure changes, minimizing downtime.

4. Maintenance Protocols Training should emphasize routine maintenance practices, including cleaning filters, checking refrigerant levels, and monitoring system performance to prevent potential issues.

5. Energy Efficiency Practices In an era where energy costs are rising, training can highlight methods for optimizing chiller efficiency, leading to cost savings and reduced environmental impact.

industrial chiller training supplier

Selecting a Reliable Training Supplier

When it comes to selecting a training supplier for industrial chillers, there are several factors to consider

1. Reputation and Experience Choose a supplier with a proven history in the industry. Established suppliers typically have a wealth of knowledge and can provide insights based on real-world applications.

2. Customized Training Solutions Look for suppliers willing to tailor training programs to meet the specific needs of your organization, considering factors like the types of chillers used and the expertise level of the participants.

3. Instructor Qualifications The effectiveness of training heavily relies on the instructors. Ensure that the training supplier employs experienced professionals with both theoretical knowledge and practical experience in the field.

4. Hands-On Training Practical, hands-on training allows participants to engage directly with the equipment they will be working on. This experience is invaluable for enhancing understanding and building confidence.

5. Ongoing Support and Resources A reliable training supplier should offer ongoing support, including access to resources, updates on industry standards, and refresher courses as necessary.

6. Feedback and Improvement Process Choose a supplier that encourages feedback from participants and is willing to improve their programs based on the insights gathered.

Conclusion

Investing in industrial chiller training is essential for any organization that relies on these systems for operational efficiency. By selecting a reputable training supplier, businesses can ensure their teams are well-prepared to operate, maintain, and troubleshoot chillers effectively. This not only promotes a culture of safety and efficiency within the organization but also contributes to overall productivity and cost savings. In an increasingly competitive industrial landscape, proper training is not just an option; it is a necessity for success.