air cooled industrial water chiller manufacturer

The Rise of Air-Cooled Industrial Water Chillers A Comprehensive Overview

In the ever-evolving landscape of industrial cooling solutions, air-cooled water chillers have emerged as a preferred choice for various applications. As manufacturers innovate and optimize these systems, the demand for reliable, efficient, and cost-effective cooling solutions continues to grow. This article explores the key features, benefits, and advancements in air-cooled industrial water chillers, highlighting their significance in modern industrial processes.

Understanding Air-Cooled Industrial Water Chillers

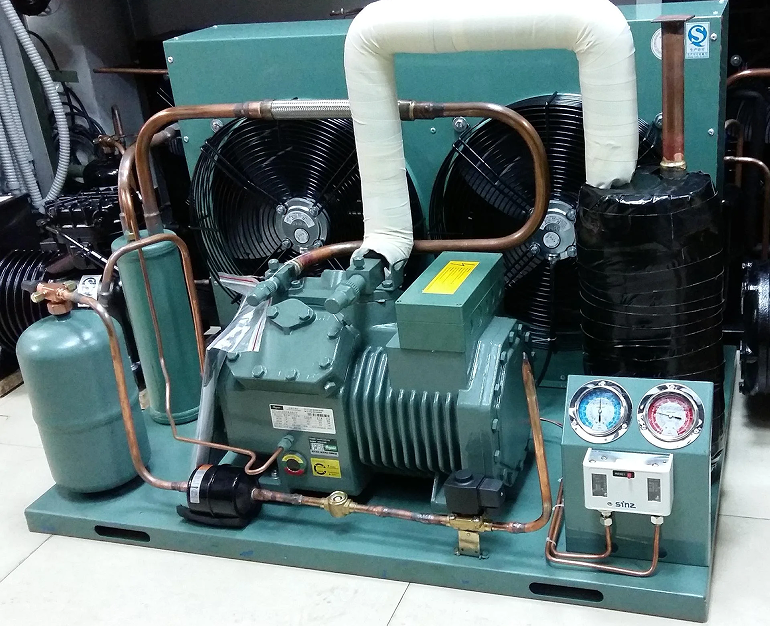

An air-cooled industrial water chiller is a type of refrigeration system that uses ambient air to cool a fluid, typically water, which is then circulated through industrial processes to maintain desired temperatures. Unlike water-cooled chillers that require cooling towers and extensive plumbing, air-cooled chillers operate efficiently by utilizing fans to draw in air, transferring heat from the refrigerant to the environment. This simplicity in design makes them particularly advantageous for certain industrial applications.

Key Features of Air-Cooled Industrial Water Chillers

1. Energy Efficiency One of the most significant advantages of air-cooled chillers is their energy efficiency. Modern refrigerants and advanced compressor technologies enhance energy savings, reducing operational costs for manufacturers.

2. Low Maintenance Air-cooled chillers have fewer components than their water-cooled counterparts, resulting in lower maintenance requirements. There are no cooling towers to manage, and the systems are generally easier to service.

3. Compact Design These chillers are typically more compact than water-cooled units, making them ideal for facilities with limited space. Their design allows for easy installation in various environments, from factories to commercial buildings.

4. Environmentally Friendly With a focus on sustainability, manufacturers are increasingly using eco-friendly refrigerants in air-cooled chillers. These refrigerants have a lower global warming potential (GWP), aligning with global environmental standards.

5. Versatility Air-cooled chillers can be used for a wide range of applications, including plastics manufacturing, food and beverage processing, pharmaceuticals, and HVAC systems. Their ability to cater to diverse industrial needs makes them a versatile choice.

Benefits of Using Air-Cooled Industrial Water Chillers

air cooled industrial water chiller manufacturer

The rise in the adoption of air-cooled chillers can be attributed to several compelling benefits

- Cost-Effectiveness Air-cooled chillers tend to have lower initial costs compared to water-cooled systems. Their installation is often quicker and less complex, leading to reduced labor expenses. - Reduced Footprint The compact nature of air-cooled chillers allows for more efficient use of space within a facility, facilitating optimal layout planning and equipment placement.

- Geographical Flexibility These chillers can be installed in a variety of locations, even in areas where water supply may be limited or where environmental regulations restrict the use of water-cooling methods.

- Rapid Deployment For industries experiencing sudden changes in cooling demand, air-cooled chillers can be quickly deployed as a temporary solution or as part of a scaling operation.

Advancements in Air-Cooled Chiller Technology

The landscape of air-cooled industrial water chillers is continuously evolving, driven by technological advancements. Some notable improvements include

- Smart Controls Integrating IoT and smart monitoring systems allows for real-time temperature monitoring, predictive maintenance, and energy consumption tracking, optimizing performance and efficiency.

- Variable Speed Drives (VSD) The use of VSDs in compressors enhances the ability to adjust cooling output based on demand, leading to significant energy savings during periods of low load.

- Modular Design Manufacturers are increasingly offering modular chillers that can be expanded as cooling requirements grow, offering scalability and flexibility to business operations.

Conclusion

As industries face rising demands for efficient and adaptable cooling solutions, air-cooled industrial water chillers stand out as a robust and sustainable option. Their energy efficiency, low maintenance needs, and versatility make them invaluable assets in various sectors. With continuous innovations paving the way for enhanced performance and environmental stewardship, the future of air-cooled chillers is bright, promising further contributions to industrial efficiency and sustainability. As a leading manufacturer in this domain, investing in high-quality air-cooled chillers is a strategic move towards achieving operational excellence and meeting the cooling needs of today's dynamic industrial environment.