cold storage room sizes factory

Understanding Cold Storage Room Sizes in Factories

In today’s globalized economy, efficient supply chain management is crucial for the success of food and pharmaceutical industries. One of the key components of this management is the cold storage room, which plays a vital role in preserving the quality and safety of perishable goods. Understanding the optimal sizes of cold storage rooms in factories is essential for maximizing efficiency and meeting regulatory standards.

Understanding Cold Storage Room Sizes in Factories

When designing a cold storage room, it is crucial to consider the specific requirements for temperature and humidity control. For instance, fresh produce may require different environmental conditions compared to frozen foods or pharmaceutical products. Therefore, understanding the types of goods being stored is the first step in determining the appropriate size. A factory that primarily stores large quantities of frozen foods will need a larger facility compared to one that holds smaller quantities of mixed products.

cold storage room sizes factory

Another important consideration is the volume of inventory. Factories must analyze their storage capacity needs, projecting future demand to avoid the pitfalls of overcrowding or underutilization. Overcrowded storage can lead to compromised air circulation, resulting in uneven temperatures that can spoil products, while underutilization can increase operational costs. A well-planned cold storage room optimizes space while allowing for growth and adaptation to changing market demands.

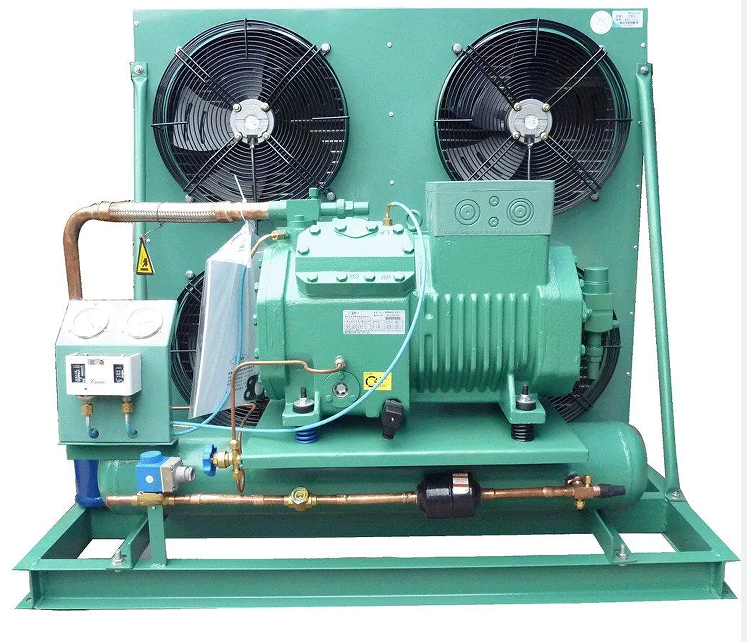

Operational efficiency is yet another factor influencing cold storage room design. Factories must consider workflow, including how products are received, stored, and distributed. The layout of the storage room should facilitate easy access to goods, minimizing the time that employees spend in the area, which is essential for maintaining the desired temperature. Furthermore, equipment such as shelving, pallets, and refrigeration units must be factored into the room’s dimensions to ensure operational efficiency.

Regulatory compliance is also critical when determining cold storage room sizes. Many industries are subject to stringent food safety and quality regulations, necessitating specific temperature controls and monitoring capabilities. Factories should familiarize themselves with local regulations to avoid potential fines or penalties related to health and safety violations.

In conclusion, the size of cold storage rooms in factories is determined by various factors, including the types of goods stored, inventory volume, operational efficiency, and regulatory compliance. A thorough understanding of these elements allows factory managers to design effective cold storage solutions that meet both current needs and future challenges, ultimately ensuring the quality and safety of products. Proper planning and implementation of cold storage facilities are key to sustaining business operations while adhering to industry standards.

-

Transform Operations with Vacuum Freezer MachineNewsMay.14,2025

-

Enhance Business with Cold Room TechnologyNewsMay.14,2025

-

Vacuum Freezer Machine for Modern NeedsNewsMay.09,2025

-

Discover Our Comprehensive Cold Room SolutionsNewsMay.09,2025

-

Cold Room Solutions for Your BusinessNewsMay.08,2025

-

Advanced Vacuum Freezer MachineNewsMay.08,2025