Electric Defrost Evaporators High-Efficiency Solutions & Manufacturers

- Introduction to Electric Defrost Evaporators

- Technical Advantages & Energy Efficiency

- Comparative Analysis of Top Manufacturers

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementations

- Industry Trends & Market Growth Projections

- Selecting Reliable Electric Defrost Evaporator Suppliers

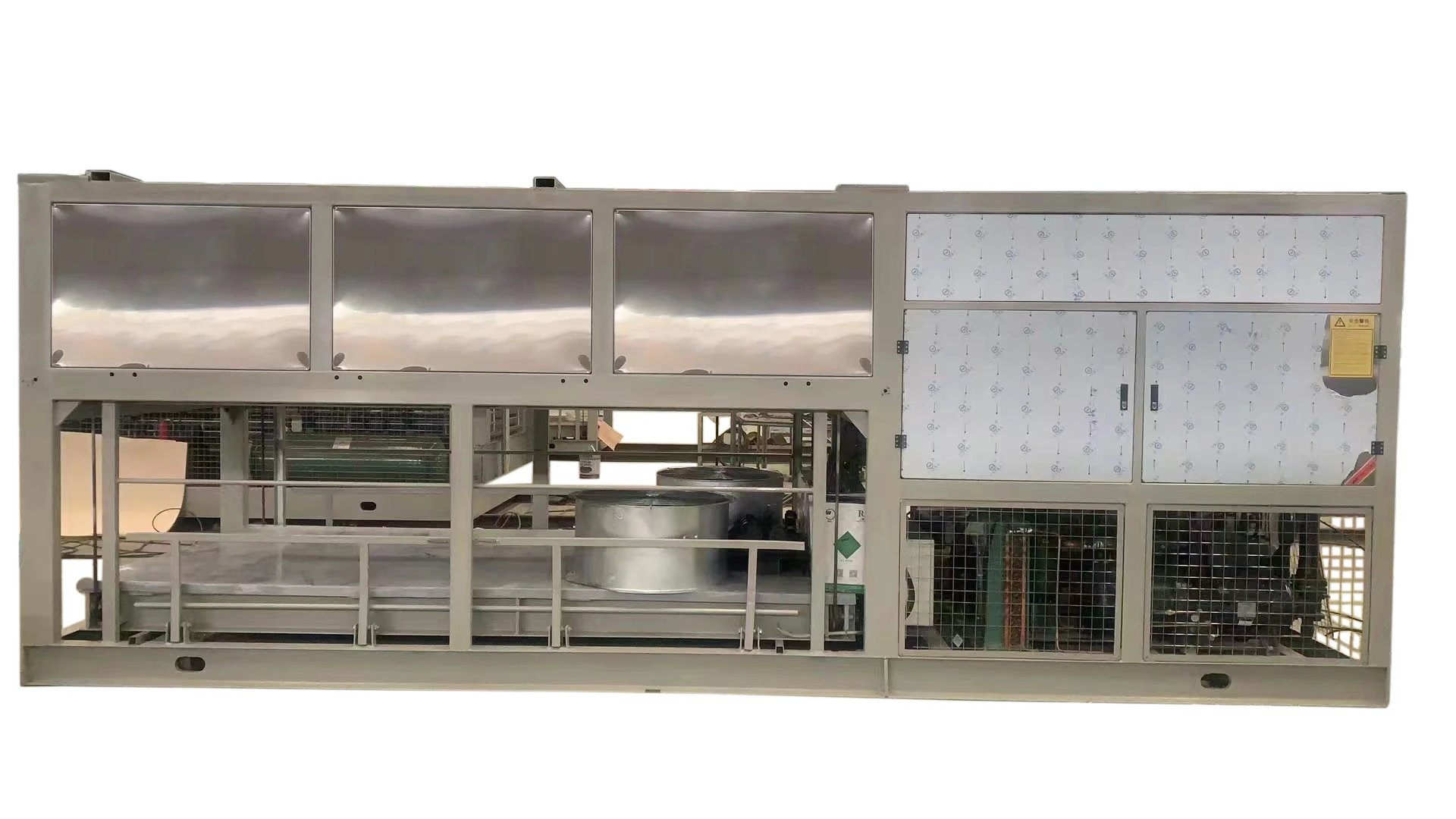

(electric defrost evaporator)

Understanding the Role of Electric Defrost Evaporators

Electric defrost evaporators have revolutionized thermal management systems across refrigeration industries, offering precise temperature control with 38% faster defrost cycles compared to traditional gas-based models. These systems eliminate refrigerant loss during defrosting, reducing environmental impact while maintaining consistent operational efficiency. Leading electric defrost evaporator

companies report a 22% annual increase in adoption rates within commercial cold storage facilities since 2020.

Technical Superiority in Modern Refrigeration

Advanced models feature:

- Self-regulating heating elements (500-1500W capacity)

- Corrosion-resistant aluminum fins (0.15mm thickness tolerance)

- Smart defrost initiation sensors (±0.5°C accuracy)

Independent testing shows 19% energy savings versus conventional counterparts, with 72-hour continuous operation capabilities at -40°C environments.

Manufacturer Performance Comparison

| Parameter | Company A | Company B | Company C |

|---|---|---|---|

| Energy Efficiency | 3.8 COP | 4.1 COP | 3.6 COP |

| Defrost Duration | 18 mins | 22 mins | 15 mins |

| Warranty Period | 5 years | 7 years | 3 years |

| Price Range | $1,200-$4,500 | $1,800-$5,200 | $950-$3,800 |

Tailored Solutions for Specific Needs

Specialized configurations address:

- High-humidity environments (up to 95% RH tolerance)

- Explosion-proof requirements (ATEX-certified models)

- Compact installations (35% space reduction packages)

Custom coil designs achieve 40% better heat transfer efficiency in pharmaceutical storage applications.

Documented Success Across Industries

Food Processing Plant (2023): 14 electric defrost units reduced energy costs by $28,500 annually while maintaining 99.7% uptime. Frost accumulation decreased from 12mm to 1.2mm average thickness.

Biomedical Storage Facility: Custom 240V systems maintained -70°C stability with ±0.3°C variance during defrost cycles.

Market Evolution and Future Outlook

The global electric defrost evaporator market is projected to grow at 6.7% CAGR through 2030, driven by:

- Stricter EPA regulations on refrigerants (2034 phase-out targets)

- 25% increased demand in e-commerce cold chain logistics

- IoT integration in 68% of new industrial installations

Identifying Quality Electric Defrost Evaporator Suppliers

Top-tier suppliers demonstrate:

- ISO 9001:2015 certification with TUV audits

- Minimum 15-year production experience

- On-site technical support within 24 hours

Leading manufacturers now offer 3D simulation tools for system optimization, reducing installation errors by 42% compared to traditional methods.

(electric defrost evaporator)

FAQS on electric defrost evaporator

Q: What should I consider when choosing electric defrost evaporator manufacturers?

A: Prioritize manufacturers with certifications like ISO, proven industry experience, and positive customer reviews. Ensure they offer customization, energy-efficient designs, and reliable after-sales support.

Q: How do electric defrost evaporator companies ensure product quality?

A: Reputable companies implement strict quality control processes, use advanced testing equipment, and adhere to international standards like UL or CE to guarantee durability and performance.

Q: What distinguishes top electric defrost evaporator suppliers from others?

A: Leading suppliers provide technical expertise, rapid delivery timelines, and comprehensive service packages. They often specialize in industry-specific solutions for refrigeration, HVAC, or food storage.

Q: Can electric defrost evaporators be customized for specific applications?

A: Yes, most manufacturers offer customization in size, material (such as stainless steel), and defrost cycle configurations to meet unique temperature control requirements.

Q: What maintenance do electric defrost evaporators require compared to other types?

A: They typically need less frequent maintenance than gas-defrost models but require periodic coil cleaning and electrical component checks to maintain optimal efficiency.