Suppliers for Electric Defrost Systems in Evaporator Technology and Solutions

The Rise of Electric Defrost Evaporator Suppliers Revolutionizing Refrigeration Technology

In today's rapidly advancing technological landscape, the demand for efficient and innovative refrigeration solutions has never been higher. One of the pivotal components that have been receiving increasing attention is the electric defrost evaporator. This technology has significantly enhanced the efficiency of refrigeration systems, minimizing energy consumption while maximizing performance. Consequently, the emergence of electric defrost evaporator suppliers is shaping the future of the refrigeration industry.

Understanding Electric Defrost Evaporators

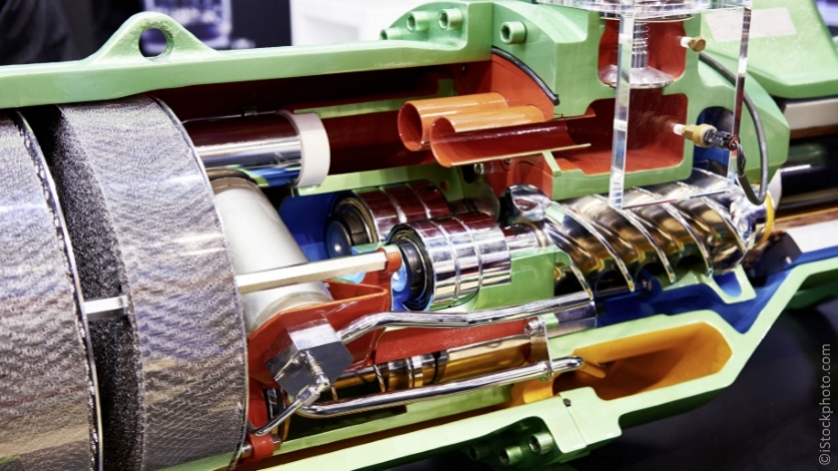

Electric defrost evaporators are essential components in refrigeration systems, especially in commercial and industrial settings. Unlike traditional systems that rely on gas or hot gas for defrosting, electric defrosting utilizes electric heating elements. This process melts any accumulated frost or ice on the evaporator coils, ensuring optimal heat exchange. The benefits of electric defrosting extend beyond simple functionality; they include improved efficiency, reduced frost buildup, and lower maintenance costs.

Why the Shift to Electric Defrosting?

The transition to electric defrost systems is driven by several key factors

1. Energy Efficiency Electric defrost systems typically consume less energy than their counterparts. By optimizing the defrost cycle, these systems can reduce overall energy costs, making them an attractive option for businesses looking to minimize operational expenses.

2. Consistency in Performance Traditional defrost methods can lead to uneven temperatures and inefficient operation. Electric defrosting ensures a uniform and consistent performance, which is critical for preserving the integrity of perishable goods in commercial refrigeration units.

3. Environmental Impact As sustainability takes center stage in the industrial sector, the need for environmentally friendly solutions has intensified. Electric defrost systems reduce the reliance on refrigerants known for their environmental impact, aligning with global initiatives aimed at reducing carbon footprints.

4. Safety and Reliability Electric defrost technologies provide a safer alternative by minimizing the risk of leaks associated with gas systems. Furthermore, the reliability of electric heating elements reduces the chances of system failures, ensuring uninterrupted operation.

The Role of Suppliers in the Market

electric defrost evaporator suppliers

As the demand for electric defrost evaporators grows, so does the need for specialized suppliers. These suppliers play a crucial role in the development and distribution of cutting-edge defrost technologies. Their responsibilities include

- Research and Development Suppliers are at the forefront of innovation, continuously developing advanced electric defrost systems that cater to the specific needs of various industries. This R&D focus ensures that suppliers remain competitive and meet the ever-evolving demands of their customers.

- Quality Assurance Given the critical nature of refrigeration in food safety and other applications, suppliers are dedicated to maintaining high standards of quality. They implement rigorous testing procedures to ensure their products are reliable and efficient, dealing with factors such as energy consumption and defrosting time.

- Technical Support and Training Many suppliers go beyond just supplying equipment; they provide technical support and training for their clients. This ensures that customers can operate and maintain their systems effectively, maximizing the benefits of electric defrost technology.

- Customization Options Every business has unique refrigeration needs. Top suppliers offer customization options that allow clients to tailor defrost systems according to their specific requirements, leading to increased efficiency and better operational performance.

Industry Trends and the Future of Electric Defrosting

As we look to the future, several trends are shaping the electric defrost evaporator market

- Integration with IoT Technology The integration of the Internet of Things (IoT) in refrigeration systems is enhancing monitoring and control capabilities. Suppliers are expected to develop smart defrost systems that can be remotely monitored and controlled, leading to smarter energy use and predictive maintenance.

- Sustainability Focus With an increasing emphasis on sustainability, suppliers are looking to develop electric defrost systems that reduce energy consumption and environmental impact, further advancing green technology in refrigeration.

- Global Expansion The market for electric defrost evaporators is expanding globally. Suppliers are exploring new markets and opportunities, driven by a growing recognition of the benefits of electric defrosting in diverse applications.

In conclusion, the emergence of electric defrost evaporator suppliers marks a significant evolution in refrigeration technology. Their role in promoting energy efficiency, safety, and reliability is essential for businesses aiming to stay competitive in an increasingly conscientious market. As technology continues to advance, we can expect to see further innovations that will make electric defrosting an indispensable aspect of refrigeration systems across various industries.