Efficient Ice Cleaning Machinery Manufacturing for Enhanced Performance in Various Industries

Ice Cleaner Machine Factory Revolutionizing Ice Maintenance

In the fast-paced world of sports and entertainment, maintaining pristine ice surfaces is critical for both functionality and aesthetics. Ice cleaner machines have become indispensable tools for arenas, rinks, and other ice facilities, ensuring optimal conditions for players and spectators alike. An ice cleaner machine factory specializes in the design, manufacturing, and distribution of these innovative machines, contributing significantly to the ice rink industry.

Understanding Ice Cleaner Machines

Ice cleaner machines, often referred to as ice resurfacers or zambonis, are essential for maintaining high-quality ice surfaces. These machines work by removing snow, shavings, and other debris accumulated during ice use. They then lay down a fresh layer of water, which quickly freezes to create a smooth playing surface. The efficiency and effectiveness of these machines directly affect the quality of ice, impacting everything from skating performance to safety.

The Manufacturing Process

At an ice cleaner machine factory, the manufacturing process involves a blend of advanced engineering and precision craftsmanship. The design starts with extensive research and development, focusing on the latest technologies and materials. Engineers collaborate to create efficient water distribution systems, powerful engines, and effective snow removal mechanisms.

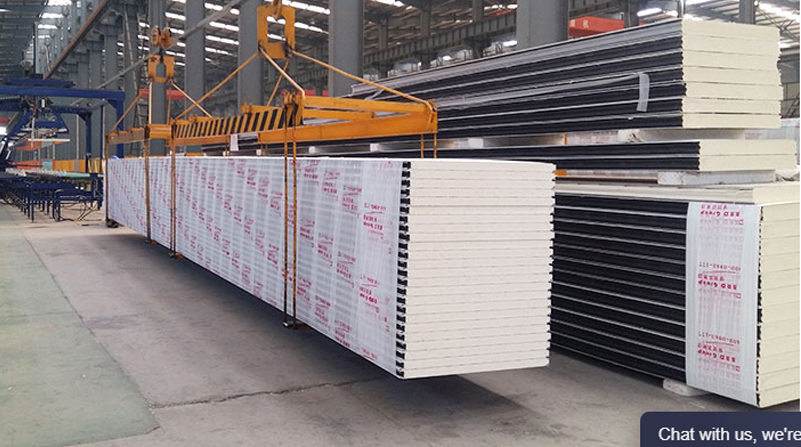

Once the design is finalized, production begins. Factories are equipped with state-of-the-art machinery that shapes and assembles components. This includes cutting-edge robotics and automation systems that streamline manufacturing while ensuring high precision. Quality control measures are critical throughout this process, as the machines must withstand rigorous conditions and continuous use.

Innovation and Technology

ice cleaner machine factory

The ice cleaning industry has experienced significant technological advancements over recent years. Modern ice cleaner machines come equipped with features such as electric drivetrains, automated controls, and enhanced water recycling systems. These innovations not only improve the performance of the machines but also make them more environmentally friendly.

For instance, electric ice resurfacers reduce greenhouse gas emissions compared to their gas-powered counterparts. They also provide a quieter operation, which is a significant advantage for venues hosting events and spectators. Furthermore, the integration of smart technology allows operators to monitor machine performance in real time, facilitating preventative maintenance and reducing downtime.

Meeting Diverse Needs

Ice cleaner machine factories cater to a variety of markets, including professional sports arenas, community recreational facilities, and even private ice rinks. Each of these markets has unique requirements that the factory must address. For instance, professional teams demand high-performance machines that can deliver flawless ice quickly, while community rinks may prioritize cost-effectiveness and ease of use.

To meet these diverse needs, manufacturers often offer a range of models and customizable options. From compact models for smaller rinks to large, robust machines designed for major league arenas, there is an ice cleaner machine to suit any venue.

The Future of Ice Maintenance

As the demand for ice sports and activities continues to grow, so too does the need for reliable ice maintenance solutions. Ice cleaner machine factories are poised to play a pivotal role in this evolution. By embracing sustainability, integrating advanced technologies, and responding to market demands, these factories can lead the way in enhancing ice quality for years to come.

In conclusion, the ice cleaner machine factory is not just a manufacturer; it is a vital contributor to the sports and entertainment landscape. Through innovation and dedication, these factories ensure that players can achieve their best performance on the ice, creating a better experience for everyone involved. As the industry moves forward, the commitment to quality and efficiency in ice maintenance will remain at the forefront, ensuring that every game is played on the best possible surface.