Scroll Water Cooled Chiller Manufacturing Facilities Overview and Innovations

Scroll Water Cooled Chiller Factories An Overview

In today's industrial landscape, the demand for efficient cooling systems has led to innovations in chiller technology, particularly in the development of scroll water-cooled chillers

. These systems are pivotal in various applications, including commercial buildings, industrial processes, and large-scale facilities, due to their energy efficiency, compact design, and reliable performance.Scroll water-cooled chillers utilize a closed-loop cooling process that leverages the compression of refrigerant vapor in scroll compressors, rendering them distinct from traditional chiller systems. These chillers serve as heat exchangers that transfer heat from a building or process to the water, which is then cooled and circulated through the system. The production of these chillers occurs in specialized factories equipped with state-of-the-art technology and skilled labor.

Manufacturing scroll water-cooled chillers requires precision engineering and meticulous quality control processes. Factories typically follow a systematic approach, beginning with the design stage, where engineers use advanced software for thermal modeling and simulations. This ensures that the chillers meet industry standards and customer specifications while optimizing performance metrics such as energy consumption and cooling capacity.

scroll water cooled chiller factories

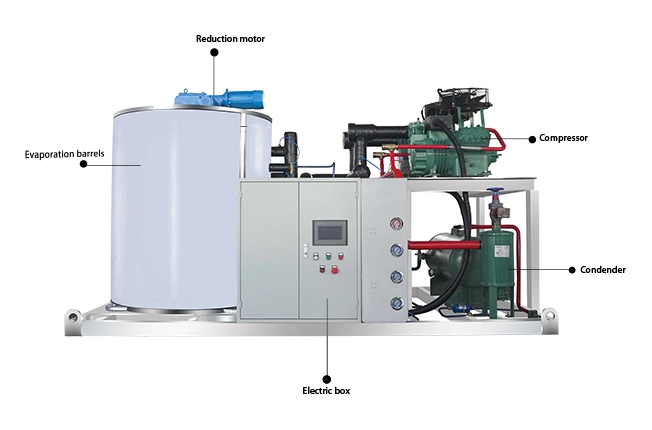

Once the design is finalized, the production phase commences. Factories utilize modern fabrication techniques, including CNC machining and robotic assembly, to manufacture individual components such as scroll compressors, evaporators, and condensers. The production line is often configured for efficiency, allowing for the rapid assembly of chillers while maintaining high quality.

Quality control is paramount in the manufacturing process. Each component undergoes rigorous testing before assembly, including pressure tests and performance evaluations. Once completely assembled, the chillers are subjected to a series of tests to ensure they meet the energy efficiency and performance standards set by regulatory bodies. This commitment to quality not only assures the reliability of the product but also enhances its longevity, which is a significant selling point for customers.

After passing all tests, the finished scroll water-cooled chillers are prepared for shipment. Factories often maintain a close relationship with logistics partners to ensure timely delivery to customers across various sectors. Moreover, many manufacturers offer installation and maintenance services, providing customers with comprehensive solutions beyond the purchase of the unit.

In conclusion, scroll water-cooled chiller factories play a crucial role in the production of efficient and reliable cooling systems. Through advanced manufacturing techniques, stringent quality control, and a strong focus on customer satisfaction, these facilities contribute significantly to the advancements in chiller technology, ultimately meeting the rising demand for energy-efficient solutions in today’s competitive environment. This ongoing evolution in manufacturing not only addresses immediate cooling needs but also aligns with broader sustainability goals, making scroll water-cooled chillers an essential component in modern infrastructure.