Water-Cooled Scroll Chiller Manufacturer for Efficient Climate Control Solutions

Water-Cooled Scroll Chiller A Comprehensive Overview of Manufacturing and Benefits

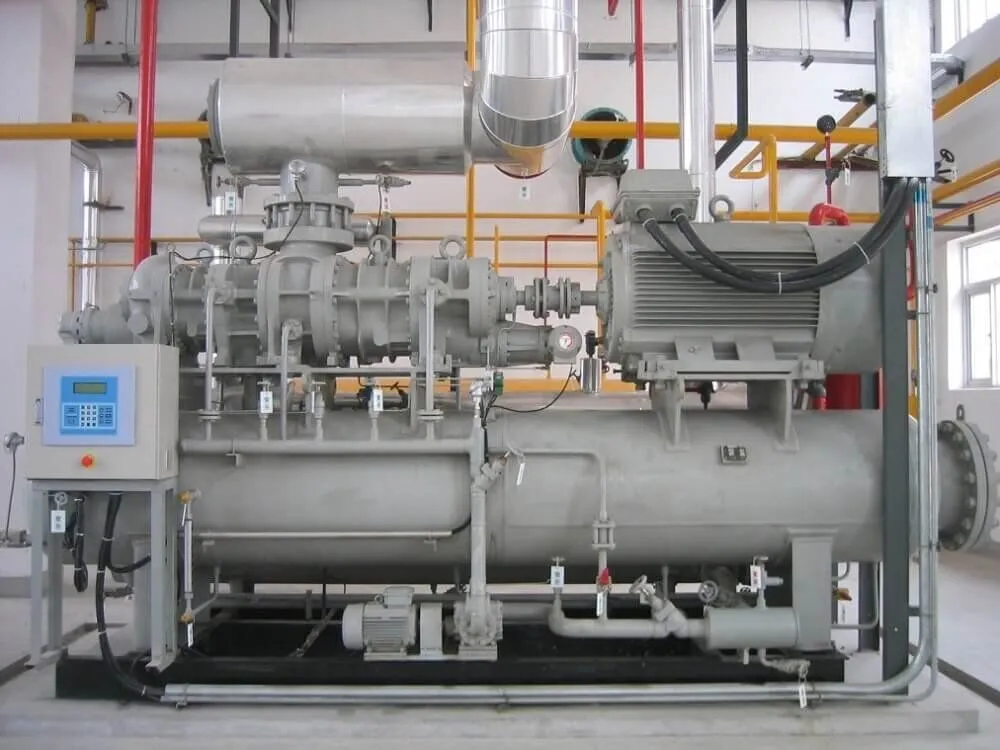

In the realm of modern HVAC systems, water-cooled scroll chillers have emerged as one of the most efficient and reliable cooling solutions for commercial and industrial applications. With a growing demand for energy efficiency and robust cooling capabilities, these chillers have garnered significant attention in manufacturing processes around the world. This article delves into the intricacies of water-cooled scroll chiller factories, their production processes, and the advantages they offer to various industries.

Understanding Water-Cooled Scroll Chillers

Water-cooled scroll chillers utilize a scroll compressor design to circulate refrigerant and provide cooling. Unlike air-cooled chillers, which rely on ambient air to remove heat, water-cooled chillers use water supplied from cooling towers or other sources. This method enhances efficiency, making water-cooled scroll chillers ideal for large-scale operations, including commercial buildings, hospitals, and industrial plants.

The Manufacturing Process

Manufacturing a water-cooled scroll chiller involves several key steps, ensuring that each unit meets stringent quality and performance standards. The process begins with the selection of high-quality raw materials, including steel, copper, and specialized polymers, which are crucial for the durability and efficiency of the chiller components.

1. Component Fabrication The first stage of production involves fabricating various components, such as the scroll compressor, evaporator, condenser, and expansion valve. Advanced machinery and precision engineering techniques are employed to manufacture these parts, guaranteeing their compatibility and performance.

2. Assembly Line Once the components are fabricated, they move to the assembly line. Skilled technicians carefully assemble the scroll compressor with the evaporator and condenser. This assembly requires a high level of expertise, as the precise alignment of the scroll components is critical for optimal performance and efficiency.

3. Refrigerant Charging After assembly, the chiller is charged with refrigerant. This step is crucial, as the right amount of refrigerant ensures efficient cooling and prevents issues like excessive pressure and temperature fluctuations.

4. Testing and Quality Control The manufactured chillers undergo rigorous testing to ensure they meet safety and efficiency standards. Tests include performance assessments under various loads, pressure tests, and temperature evaluations. Only those chillers that pass these tests are deemed ready for shipment.

water cooled scroll chiller factory

5. Final Inspection and Packaging The last stage involves a final inspection where quality control teams examine the units for any defects. Once cleared, the chillers are packaged carefully to prevent any damage during transportation.

Advantages of Water-Cooled Scroll Chillers

The efficiency and reliability of water-cooled scroll chillers present several distinct advantages for users

1. Energy Efficiency One of the most significant benefits is their energy efficiency. Water-cooled scroll chillers generally operate at lower energy costs compared to their air-cooled counterparts, particularly in large installations. The use of water as a cooling medium allows for higher heat transfer rates, leading to reduced energy consumption.

2. Space-Saving Design These chillers typically require less space due to their compact design, making them suitable for urban environments where space is at a premium. Their modular nature allows for easier installation and integration into existing systems.

3. Quiet Operation Scroll compressors operate more quietly than traditional reciprocating compressors. This characteristic reduces noise pollution, making water-cooled scroll chillers an excellent choice for buildings requiring a peaceful environment, such as educational institutions and hospitals.

4. Environmentally Friendly With the increasing concern over greenhouse gas emissions, many manufacturers are now using refrigerants with lower global warming potential (GWP) in their chillers. This commitment to sustainability aligns with global efforts to reduce carbon footprints.

5. Low Maintenance Requirements Water-cooled chillers are known for their durability and reliability, leading to lower maintenance costs over their operational lifespan. Regular maintenance, when performed, ensures sustained performance and longevity.

Conclusion

As industries continue to evolve and demand for efficient cooling solutions rises, water-cooled scroll chills stand at the forefront of HVAC technology. The manufacturing process of these chillers reflects an intricate blend of precision engineering and innovative design, resulting in a product that not only meets but exceeds modern cooling requirements. Their numerous advantages, including energy efficiency, compact design, and low noise levels, make them a favorable choice across various applications, ensuring that they remain an integral part of the HVAC landscape for years to come.