monoblock freezer unit factories

The Rise of Monoblock Freezer Unit Factories

In the modern world of refrigeration, the demand for efficient and reliable cooling solutions has never been greater. The monoblock freezer unit, a self-contained system that integrates both the compressor and evaporator into a single unit, has gained popularity across various industries. With factories dedicated to the production of these monoblock freezer units springing up around the globe, it’s essential to understand their significance, benefits, and the standards guiding their manufacture.

What is a Monoblock Freezer Unit?

A monoblock freezer unit refers to a freezer system constructed as a single unit, simplifying the installation process. Unlike traditional freezers, which require separate components for the compressor, condenser, and evaporator, monoblock systems unite these parts into one compact unit. This design not only allows for easier installation and maintenance but also increases the overall efficiency of the freezing process.

Advantages of Monoblock Freezer Units

1. Space Efficiency Monoblock units are typically smaller than traditional freezer setups, making them ideal for businesses with limited space. Their compact design allows them to fit into various settings, from small restaurants to large supermarkets.

2. Energy Efficiency These units are engineered to consume less energy while delivering effective cooling. Innovative technologies, such as variable speed compressors and efficient insulation materials, enable monoblock freezers to maintain low temperatures with minimal energy expenditure.

3. Ease of Maintenance With all critical components housed in a single unit, maintenance becomes more straightforward. This design reduces the risk of common issues associated with separate components, leading to fewer breakdowns and lower repair costs.

4. Flexibility Monoblock freezers come in various sizes and capacities, making them adaptable to diverse commercial requirements. Whether used for storing ice cream, seafood, or pharmaceuticals, these units can be customized to meet specific cooling needs.

5. Environmentally Friendly Modern monoblock freezer units often utilize refrigerants and technologies that are less harmful to the environment. Many manufacturers are committed to producing units that comply with stringent environmental standards, minimizing their carbon footprint.

monoblock freezer unit factories

The Manufacturing Process

The production of monoblock freezer units involves several key steps, ensuring that each unit meets both quality and performance standards

1. Design and Engineering Engineers carefully design each component of the monoblock system, considering factors such as airflow, cooling capacity, and energy efficiency. Advanced software is often used to simulate performance before production begins.

2. Materials Selection High-quality materials, including durable metals and advanced insulation foam, are selected for their thermal properties and structural integrity. The choice of materials is crucial for the unit's performance and longevity.

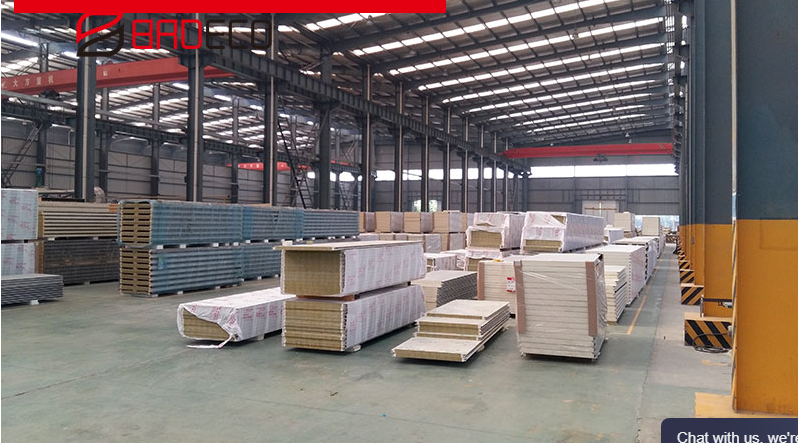

3. Assembly Line Production Factories utilize automated assembly lines to enhance efficiency and precision. Each unit is assembled with attention to detail, ensuring that all components fit together seamlessly.

4. Quality Control Rigorous testing is conducted to ensure that every monoblock freezer unit meets the strictest industry standards. This can include tests for cooling efficiency, energy consumption, and durability.

5. Distribution Once manufactured, units are shipped to distributors or directly to customers, often accompanied by warranties that assure buyers of their reliability.

Conclusion

The advent of monoblock freezer unit factories signifies a transformative shift in the refrigeration industry. With their numerous advantages, including energy efficiency, space-saving designs, and ease of maintenance, these systems are becoming essential for businesses seeking reliable cooling solutions. As technology continues to evolve, the future of monoblock freezer units looks bright, offering enhanced features and even greater sustainability. Factories dedicated to their production play a crucial role in this ongoing evolution, ensuring that businesses can rely on effective refrigeration to meet their needs. The combination of innovation, quality manufacturing, and environmental responsibility positions monoblock freezer units at the forefront of the refrigeration market.