Cold Storage Panel Recycling Solutions and Factory Management Strategies

Cold Room Panel Disposal A Sustainable Approach in Factory Settings

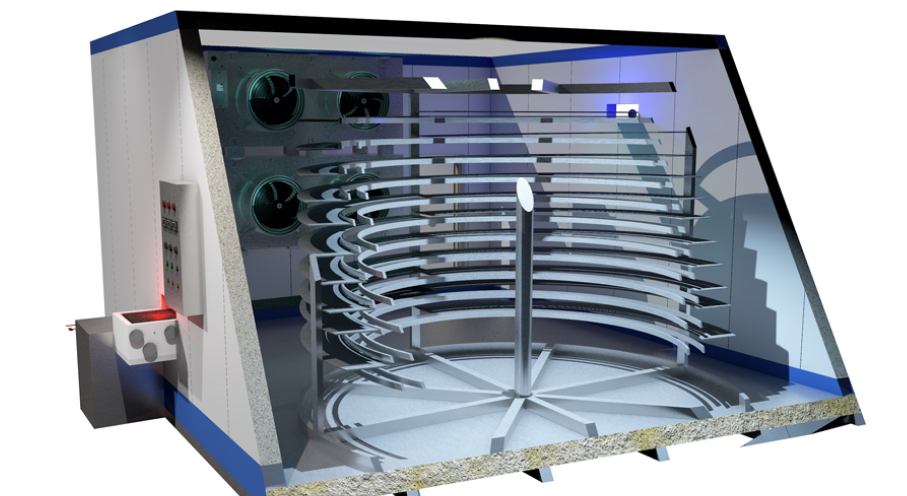

The increasing demand for cold storage facilities in the food and pharmaceutical industries has led to the widespread use of cold room panels. These panels provide the necessary insulation to maintain low temperatures, ensuring the preservation of perishable goods. However, like all industrial equipment, cold room panels eventually reach the end of their operational life. This raises an important question what happens to these panels once they are deemed unusable? The disposal of cold room panels has become a pivotal point of consideration for factories aiming to adhere to sustainability practices and environmental regulations.

Cold Room Panel Disposal A Sustainable Approach in Factory Settings

One of the most effective strategies for the disposal of cold room panels is recycling. Many factories are beginning to recognize that only a fraction of the components in cold room panels need to be discarded. For instance, the steel frames used in many panels can be easily recycled. Metal recycling facilities can repurpose these frames into new products, thus minimizing waste. Moreover, the polyurethane foam can be treated and processed into raw materials for new insulation products, further reducing the environmental burden.

cold room panel disposal factory

Another aspect of sustainable disposal involves the refurbishment and reuse of cold room panels. Many companies are now investing in the refurbishment of existing panels. This process not only extends the life of the panels, saving costs for the factory, but it also minimizes the resource consumption associated with producing new panels. Factories can refurbish panels by replacing damaged components or applying new insulating materials, making them as good as new in terms of performance.

Additionally, some factories have begun implementing a take-back program, where manufacturers take responsibility for the end-of-life handling of their products. This approach allows factories to establish partnerships with transport and recycling companies to ensure that old panels are returned for proper disposal. By taking a proactive approach, manufacturers can close the loop on their products and contribute positively to the circular economy.

Furthermore, the disposal process can also involve engaging in knowledge-sharing and collaboration with other industries. For example, various sectors such as construction, refrigeration, and waste management can come together to develop innovative solutions for the disposal of cold room panels. By pooling resources and expertise, these industries can create a synergistic relationship that promotes best practices in waste management.

In summary, the disposal of cold room panels is not just a matter of tossing them aside; it is a complex issue that requires thoughtful consideration and strategic planning. Factories must prioritize sustainable disposal methods, including recycling, refurbishment, and take-back programs. By adopting these practices, factories not only reduce their environmental footprint but also enhance their corporate responsibility. As the awareness of environmental issues grows, the focus on sustainable disposal practices will only become more critical. The industrial sector has the potential to lead the way in demonstrating how businesses can operate sustainably while meeting the demands of modern society. Embracing a sustainable approach to cold room panel disposal is an essential step towards a greener future.