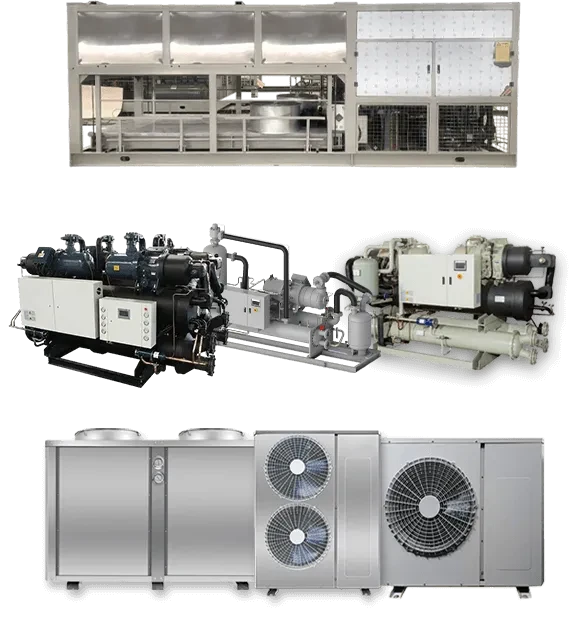

fridge condensing unit factory

The Essential Role of Fridge Condensing Unit Factories in Refrigeration Technology

In the modern world, refrigeration technology is an indispensable part of our daily lives, impacting everything from the food we eat to the pharmaceuticals we rely on. At the heart of this technology lie condensing units, specifically those used in refrigerators and freezers. Condensing units play a crucial role in the refrigeration cycle, facilitating the cooling process that keeps our perishable items fresh. This article explores the importance of fridge condensing unit factories in producing these critical components and their contributions to the efficiency and effectiveness of refrigeration systems.

Understanding Condensing Units

A condensing unit is a vital component of a refrigeration system, designed to expel heat absorbed from the interior of a fridge or freezer. This unit typically consists of a compressor, condenser, and expansion valve, each performing specific functions necessary for maintaining the refrigeration cycle. The compressor compresses refrigerant gas, raising its pressure and temperature. The condenser then cools and condenses the gas into a liquid state, allowing it to flow through the expansion valve and back into the evaporator, where it absorbs heat and begins the cycle anew.

Manufacturing Excellence in Fridge Condensing Unit Factories

Fridge condensing unit factories are specialized facilities dedicated to the production of these essential components. The manufacturing process involves multiple stages, including design, fabrication, assembly, and quality testing. High standards of engineering and manufacturing practices are critical to ensuring that each unit operates efficiently and reliably.

Innovation plays a pivotal role in the design and manufacturing of condensing units. With growing concerns about energy consumption and environmental impact, factories continuously strive to develop more energy-efficient models that use eco-friendly refrigerants. This not only helps reduce the carbon footprint of refrigeration systems but also leads to cost savings for consumers.

fridge condensing unit factory

Moreover, advancements in technology have led to the incorporation of smart features in condensing units. Modern units can be equipped with IoT (Internet of Things) capabilities, enabling remote monitoring and management. This innovation allows users to monitor temperature settings, troubleshoot issues, and optimize performance, ensuring that refrigeration systems run smoothly and efficiently.

The Market Demand and Challenges

The demand for fridge condensing units has surged in recent years, driven by the growth of the food and beverage industry, increasing urbanization, and rising consumer expectations for efficient refrigeration solutions. As online grocery shopping and food delivery services expand, the need for reliable refrigeration has become more pronounced. Consequently, condensing unit factories are working to scale production while maintaining the highest quality standards.

However, the industry faces significant challenges, including supply chain disruptions, fluctuations in raw material costs, and increasing competition. Factories must navigate these issues to ensure a consistent supply of components to meet market demands. Moreover, as regulations on refrigerants become stricter, manufacturers must adapt quickly to comply with new standards while continuing to innovate.

The Future of Fridge Condensing Units

Looking ahead, the future of fridge condensing unit factories is promising yet challenging. With the ongoing emphasis on sustainability, manufacturers are expected to enhance their production processes to minimize waste and energy consumption. Research and development will likely continue to focus on alternative refrigerants and advanced technologies that align with global sustainability goals.

In conclusion, fridge condensing unit factories are pivotal to the refrigeration industry, providing the essential components for effectively maintaining cold temperatures in various applications. Their commitment to quality, innovation, and sustainability will ultimately shape the future of refrigeration technology, ensuring that it continues to meet the needs of consumers and businesses alike. As the industry evolves, these factories will remain at the forefront of technological advancements, driving efficiency and reliability in refrigeration systems across the globe.