High-Quality IQF Freezers from Leading Manufacturers Available for Purchase

Understanding IQF Freezers A Guide for Manufacturers

In the world of food processing and preservation, Individual Quick Freezing (IQF) has emerged as a leading method for maintaining the quality and safety of perishable products. IQF freezers have gained immense popularity among manufacturers seeking to optimize their freezing processes while providing superior products to their customers. This article explores the significance of IQF freezers and highlights the benefits of sourcing high-quality models from reliable manufacturers.

What is IQF Freezing?

IQF technology involves freezing individual pieces of food rapidly at very low temperatures. This method ensures that each item freezes independently, preventing clumping and preserving the food's original texture, flavor, and nutritional value. Unlike traditional freezing methods, which can result in significant ice crystal formation, IQF minimizes this risk, leading to better quality when the food is defrosted.

The Importance of Quality in IQF Freezer Manufacturing

For manufacturers interested in IQF freezers, the choice of equipment is critical. High-quality IQF freezers contribute directly to the efficiency of production processes, the quality of the frozen products, and the overall satisfaction of end consumers. When seeking a manufacturer of IQF freezers, potential buyers should consider several factors

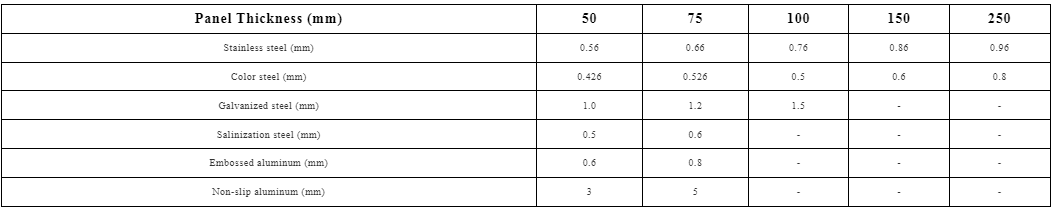

1. Quality of Materials The construction of the freezer plays a significant role in its durability and performance. Manufacturers that use high-grade materials tend to produce machines that can withstand rigorous use while maintaining optimal temperature control.

2. Technology and Innovation The freezing technology employed can vary widely. Manufacturers that invest in research and development are more likely to offer advanced solutions that enhance freezing efficiency and energy consumption. Features such as energy-efficient compressors, advanced insulation techniques, and user-friendly control systems are essential considerations.

3. Customization Options Different manufacturers have unique requirements based on their production lines and products. A reputable IQF freezer manufacturer should offer customization options to meet specific freezing needs. This might include tailored designs for different food types, output capacity, and space constraints.

4. Service Support and Maintenance After purchasing an IQF freezer, ongoing support is crucial. Manufacturers should look for companies that provide comprehensive service packages, including installation, maintenance, and troubleshooting support, to ensure long-term productivity.

iqf freezer for sale manufacturer

5. Reputation and Experience It is often beneficial to partner with established manufacturers who have a proven track record in the industry. Reading customer reviews, asking for case studies, and understanding the manufacturer's experience can help in making an informed decision.

Benefits of Using IQF Freezing Technology

1. Preservation of Quality IQF freezing locks in the freshness of food items, preserving their taste, color, and nutrients effectively. This method is especially beneficial for fruits, vegetables, seafood, and meats that would otherwise degrade quickly.

2. Extended Shelf Life Frozen products have a significantly longer shelf life compared to fresh items. This aspect is vital for manufacturers looking to reduce waste and increase profitability.

3. Flexibility in Product Offerings IQF allows manufacturers to create a diverse range of products. Whether it's frozen fruit mixes, ready-to-cook meals, or seafood assortments, the lock-in quality facilitates the exploration of new markets.

4. Ease of Portion Control With IQF, individual portions are easy to package and sell, which is advantageous for retailers catering to evolving consumer preferences for convenience and portion control.

5. Reduced Transportation Costs Efficient freezing techniques mean less product spoilage during transport. Manufacturers who employ IQF freezing often enjoy improved logistics and reduced overall transport costs.

Conclusion

In summary, IQF freezers represent a groundbreaking advancement in food freezing technology that manufacturers cannot afford to overlook. From preserving the integrity of food products to extending shelf life and enhancing market flexibility, the benefits are numerous. When searching for IQF freezers for sale, it is crucial to partner with a reputable manufacturer that offers high-quality equipment tailored to specific needs. Embracing IQF technology will not only improve operational efficiency but also drive customer satisfaction and profitability for manufacturers in the competitive food industry.