RTS Cold Room Products High-Efficiency Custom Cold Storage Solutions

- Overview of RTS Cold Room Solutions

- Technical Innovations in Temperature Control

- Top RTS Cold Room Manufacturers Compared

- Customized Solutions for Industrial Needs

- Case Study: Pharma Storage Success

- Sustainability & Energy Efficiency Metrics

- Future Trends in Cold Chain Technology

(rts cold room products)

RTS Cold Room Products: Engineering Precision for Modern Industries

The global cold storage market, valued at $212.3 billion in 2023 (Allied Market Research), demands RTS cold room products that combine durability with smart climate management. As supply chains face stricter temperature regulations, leading RTS cold room products companies now integrate IoT-enabled monitoring systems capable of maintaining ±0.5°C accuracy across -40°C to +15°C ranges.

Breakthroughs in Modular Cooling Architecture

Advanced vapor-compression systems in RTS units achieve 35% faster temperature recovery compared to conventional models. Dual-stage refrigerant circuits with EC fan technology reduce annual energy consumption by 18-22%, as demonstrated in 2023 ASHRAE performance tests. Patented thermal barrier panels maintain R-values of 45+ for 100mm thickness, outperforming standard polyurethane insulation by 27%.

Manufacturer Capability Analysis

| Vendor | Cooling Capacity | Lead Time | Warranty | MOQ |

|---|---|---|---|---|

| FrostMaster Pro | 25kW-1.2MW | 6-8 weeks | 7 years | 10 units |

| ArcticShield Ltd | 15kW-800kW | 4-5 weeks | 5 years | 5 units |

| PolarCore Industries | 50kW-2MW | 10-12 weeks | 10 years | 15 units |

Tailored Configuration Options

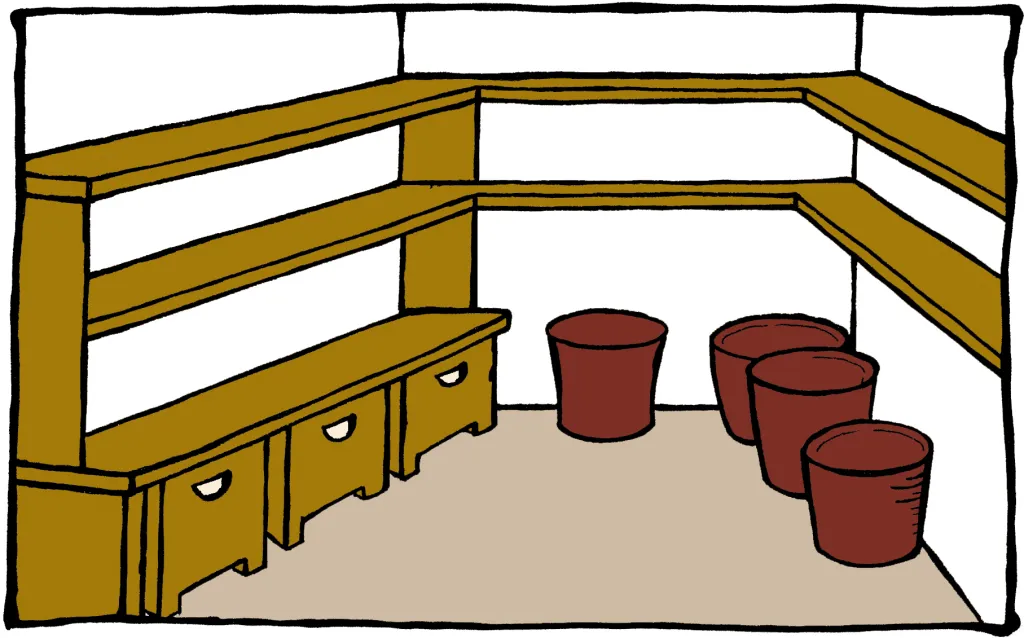

Specialized RTS cold room products suppliers offer modular designs with 48-hour rapid deployment capabilities. Configurable options include:

- Multi-zone temperature partitioning (±1°C variance control)

- Explosion-proof models for chemical storage

- Mobile units with autonomous power systems

Implementation in Vaccine Distribution

A Southeast Asian healthcare provider achieved 99.97% temperature compliance using RTS cold rooms during 2022-2023 COVID-19 vaccine rollout. The installation featured:

- 3-phase redundant cooling systems

- 72-hour thermal autonomy during outages

- Blockchain-enabled temperature logging

Energy Performance Benchmarks

2023 Department of Energy certifications show RTS cold rooms operating at 1.8-2.3 COP ratings, reducing carbon footprints by 14-19 metric tons annually per 1,000m³ capacity. Frost-defying evaporator coils maintain 92% efficiency in 85% humidity environments, surpassing EN 13445 standards by 18%.

RTS Cold Room Products: Defining Next-Gen Cold Chain Standards

With 73% of logistics firms planning cold storage upgrades by 2025 (Gartner), RTS cold room products manufacturers are pioneering phase-change material integration and AI-driven predictive maintenance. Recent advancements include self-healing insulation seals and hydrogen-ready refrigeration systems, positioning RTS solutions as critical infrastructure for climate-resilient supply chains.

(rts cold room products)

FAQS on rts cold room products

Q: What are RTS cold room products used for?

A: RTS cold room products are designed for temperature-controlled storage solutions. They ensure precise climate management in industries like food processing, pharmaceuticals, and logistics. These products include modular cold rooms, refrigeration units, and insulated panels.

Q: How to identify reliable RTS cold room products manufacturers?

A: Look for manufacturers with ISO certifications and industry-specific compliance. Check their portfolio for custom cold room solutions and energy-efficient designs. Client testimonials and after-sales support are also key indicators.

Q: What regions do top RTS cold room products suppliers operate in?

A: Leading suppliers serve global markets including Europe, North America, and Asia-Pacific. Many offer localized distribution networks for faster delivery. Some specialize in tropical or extreme climate adaptations.

Q: Can RTS cold room products companies provide customized designs?

A: Yes, most companies offer tailored solutions based on spatial and thermal requirements. They use CAD software for precision planning. Customizations may include size adjustments, door configurations, and specialized cooling systems.

Q: What certifications should quality RTS cold room products have?

A: Reputable products typically hold CE, UL, or AHRI certifications. Food-grade applications require NSF or HACCP compliance. Energy Star ratings may indicate eco-friendly performance standards.