5 ton water chiller

Understanding the 5% Ton Water Chiller Efficiency and Applications

In the realm of industrial and commercial cooling systems, the water chiller plays a pivotal role in maintaining optimal temperature levels. Specifically, a 5-ton water chiller has gained recognition for its ability to efficiently cool spaces where large volumes of air need to be regulated. This article delves into the mechanics, applications, and benefits of employing a 5-ton water chiller in various settings.

What is a 5 Ton Water Chiller?

A 5-ton water chiller refers to a cooling system that can remove heat equivalent to 5 tons of cooling capacity. This measurement originates from the capacity required to melt one ton of ice over a 24-hour period. In practical terms, this relates to approximately 60,000 BTUs (British Thermal Units), which indicates how much heat the chiller is capable of removing. These units are commonly utilized in industrial applications, commercial buildings, and even residential spaces requiring efficient air conditioning or process cooling.

The Working Mechanism

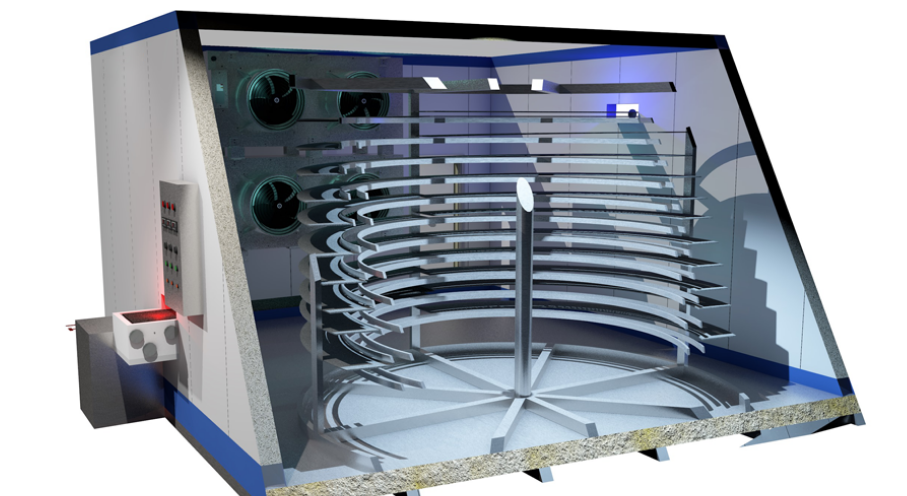

The operation of a water chiller involves a refrigeration cycle, which consists of four main components the evaporator, compressor, condenser, and expansion valve.

1. Evaporator In this section, the refrigerant absorbs heat from the water circulating within the system, causing the refrigerant to evaporate and cool the water. 2. Compressor The evaporated refrigerant then travels to the compressor, where its pressure is increased, thereby raising its temperature. 3. Condenser The high-pressure, high-temperature refrigerant gas then moves to the condenser, where it releases heat to the outside air or water, converting back into a liquid state. 4. Expansion Valve The refrigerant undergoes a pressure reduction via the expansion valve, which allows it to return to the evaporator, completing the cycle.

This process not only cools the water but also efficiently transfers heat away from the area needing cooling.

Applications of a 5 Ton Water Chiller

The versatile nature of a 5-ton water chiller makes it suitable for various applications, including

5 ton water chiller

- Commercial Buildings Offices and retail spaces utilize water chillers to maintain comfortable indoor climates for employees and customers. - Industrial Processes Factories and manufacturing plants require precise temperature control for machinery, processes, or materials, which can be achieved with a 5-ton chiller. - HVAC Systems In larger HVAC systems, water chillers provide the necessary cooling power to regulate indoor temperatures effectively. - Refrigerated Warehouses Warehousing facilities that require controlled temperatures for perishable goods often rely on water chillers for efficient cooling.

Benefits of Using a 5 Ton Water Chiller

1. Energy Efficiency With advancements in chiller technology, modern 5-ton chillers are designed to operate more efficiently, reducing energy consumption and lowering costs.

2. Cost-Effective While the initial investment may be significant, the long-term savings from reduced energy bills and maintenance costs make water chillers a cost-effective solution.

3. Environmentally Friendly Many contemporary chillers use eco-friendly refrigerants and comply with environmental regulations, contributing to a reduced carbon footprint.

4. Reliability Water chillers are known for their durability and reliability, making them a dependable choice for facilities requiring consistent cooling.

5. Scalability The modular nature of chillers allows for easy scaling, enabling businesses to upgrade or expand their systems as needed without significant overhauls.

Conclusion

A 5-ton water chiller serves as a crucial component in a variety of cooling applications, providing efficient, reliable, and cost-effective solutions across different industries. As buildings and processing environments strive to improve energy efficiency and environmental sustainability, water chillers are likely to play an even more significant role in future cooling solutions. Understanding the advantages and functionalities of these systems can help businesses make informed decisions that enhance their operations and environmental impact.