Custom Refrigeration Compressor Solutions for Cold Storage Facilities and Temperature Control

Custom Cold Room Compressor Units An Essential Component for Modern Refrigeration Solutions

In today’s rapidly evolving industries, the demand for efficient refrigeration systems is paramount. Cold rooms are crucial for preserving perishable goods across various sectors, including food storage, pharmaceuticals, and horticulture. At the heart of these cold storage solutions lies the custom cold room compressor unit—a specialized device engineered to meet specific refrigeration requirements.

Understanding Cold Room Compressor Units

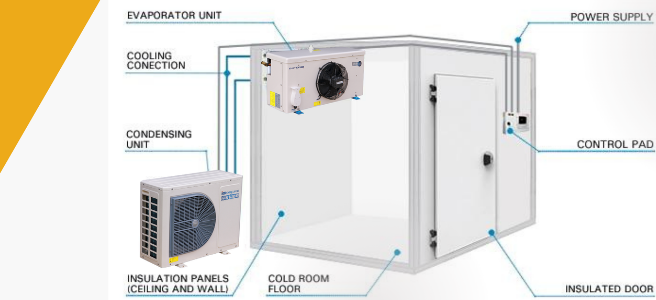

A cold room compressor unit is a mechanical device designed to remove heat from the internal environment of a cold room, thereby lowering its temperature and maintaining the desired conditions for stored items. These units typically consist of several key components the compressor, condenser, evaporator, and expansion valve. The compressor plays a pivotal role in circulating the refrigerant through the system, allowing for efficient heat exchange and temperature control.

The Importance of Customization

Why opt for a custom cold room compressor unit? The answer lies in the diversity of needs across different industries. A one-size-fits-all approach may not be effective due to variations in temperature requirements, room sizes, and product types. Custom units can be specifically tailored to accommodate these unique demands. For example, a pharmaceutical company may need a cold storage solution that maintains a constant temperature of 2 to 8 degrees Celsius for sensitive vaccines, while a food processing plant may require a system capable of reaching sub-zero temperatures for meat or seafood preservation.

Customizing a cold room compressor unit allows businesses to achieve optimal energy efficiency, reduce operational costs, and enhance the overall performance of their refrigeration systems. By selecting components that match specific capacity requirements and environmental conditions, companies can avoid overworking the system, leading to extended equipment lifespan and reduced maintenance needs.

custom cold room compressor unit

Energy Efficiency and Sustainability

In an era where sustainability is a driving force in industrial practices, custom cold room compressor units can significantly contribute to energy efficiency. By tailoring the system to meet specific load requirements, businesses can reduce energy consumption, which in turn lowers greenhouse gas emissions. Advanced features such as variable speed compressors, energy-efficient fans, and smart controls can also optimize operation, ensuring that the unit only works as hard as necessary to maintain the cold chain.

Moreover, many manufacturers now incorporate eco-friendly refrigerants that minimize environmental impact without compromising performance. This focus on sustainability not only meets regulatory requirements but also appeals to increasingly environmentally conscious consumers.

Technology Integration and Automation

Modern cold room compressor units are not just about cooling; they also incorporate advanced technology for enhanced usability and monitoring. Features like remote temperature monitoring, automated alerts, and smart control systems enable businesses to track performance in real-time. This technology integration helps in maintaining compliance with safety standards, as operators can quickly respond to any deviations in temperature that could jeopardize stored products.

Conclusion

Custom cold room compressor units are indispensable in maintaining the integrity of temperature-sensitive products across various industries. Their ability to be tailored to meet specific requirements ensures optimal performance, energy efficiency, and sustainability. As technology continues to evolve, these units will likely become increasingly sophisticated, offering businesses enhanced capabilities for managing their cold storage needs effectively. As the global market becomes more competitive, investing in a custom cold room compressor unit can provide a strategic advantage, ensuring that businesses can meet customer expectations while safeguarding their products' quality and safety.