Optimizing OEM Cold Room Efficiency Through Effective Drill Practices

The Importance of OEM Cold Room Drills Ensuring Efficiency and Safety in Cold Storage

In sectors such as food processing, pharmaceuticals, and biotechnology, maintaining an optimal temperature is crucial for the preservation of products. Cold rooms play an essential role in these industries, enabling the storage of perishable items under controlled conditions. However, the importance of having a solid operational protocol in place, particularly through OEM (Original Equipment Manufacturer) cold room drills, cannot be overstated.

Understanding OEM Cold Room Drills

OEM cold room drills are systematic training exercises designed to prepare employees for emergencies in cold storage environments. These drills simulate various scenarios that could occur, such as equipment failures, power outages, and other emergencies that necessitate immediate and effective action. By familiarizing staff with procedures and protocols, firms ensure a quick response that minimizes product loss and promotes safety.

The Necessity of Regular Drills

Regular cold room drills are not just best practices; they are essential for several reasons

1. Preparedness Employees who participate in OEM drills become adept at navigating emergency situations. Knowing the exact steps to take during a crisis reduces panic and confusion, ensuring that all staff can act swiftly and appropriately.

2. Training on Equipment Cold rooms are complex systems with various operational machines. OEM drills provide hands-on training, allowing staff to understand how to handle emergency equipment such as emergency generators, backup cooling systems, or fire suppression devices.

3. Minimizing Risks The risks associated with improper handling of cold storage areas can be substantial. Out-of-spec temperature conditions can lead to spoilage, high financial losses, and potential health hazards. Regular drills help identify weaknesses in safety protocols and encourage continuous improvement.

4. Regulatory Compliance Many industries are subject to stringent regulations concerning food safety and pharmaceutical storage. Conducting OEM cold room drills helps companies remain compliant with these regulations, avoiding potential fines and maintaining their reputations.

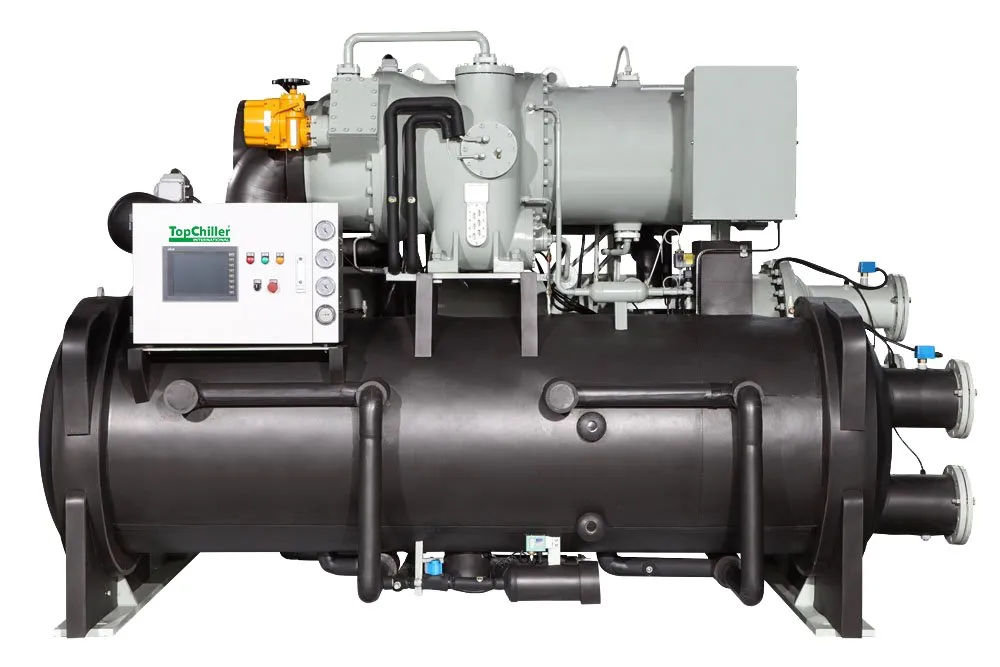

oem cold room drill

Implementing an Effective Drill Program

To harness the full benefits of OEM cold room drills, companies should implement a structured and effective drill program. Here are some steps to consider

1. Assessment of Risks Begin by conducting a risk assessment to identify potential hazards in the cold room environment. This will inform the scenarios that the drills will address.

2. Developing Standard Operating Procedures (SOPs) Create clear and concise SOPs for all emergency scenarios. These should be well-documented, easily accessible, and distributed to all employees.

3. Training and Awareness Before initiating drills, ensure that all employees are trained on the SOPs. This may involve workshops and presentations to enhance understanding.

4. Regular Scheduling of Drills Establish a regular drill schedule. This could range from monthly to quarterly, depending on the nature of the work and the risk levels.

5. Evaluation and Feedback After each drill, conduct a debriefing session to evaluate what went well and what areas need improvement. Gathering feedback from participants can inform future drills and enhance overall preparedness.

Conclusion

In conclusion, OEM cold room drills are an indispensable aspect of cold storage management. By ensuring staff are well-prepared for emergencies, companies can protect their products, ensure compliance with regulations, and promote a safe working environment. As industries evolve and face newer challenges, the importance of these drills becomes increasingly clear, enabling organizations to maintain operational excellence even in the face of adverse situations. Investing in regular OEM cold room drills is not just a choice; it is a commitment to quality, safety, and efficiency in cold storage operations.