Industrial Dry Cooler: Efficient & Reliable Process Cooling

Introduction to Industrial Dry Coolers

In the complex landscape of industrial processes, efficient thermal management is not merely a convenience but a critical determinant of operational efficiency, product quality, and system longevity. At the heart of many such systems lies the industrial dry cooler, a robust heat rejection solution designed to dissipate unwanted heat from process fluids directly into the ambient air. Unlike traditional cooling towers that rely on evaporative cooling, dry coolers operate without water consumption for cooling, making them an environmentally responsible and resource-efficient alternative, particularly in regions facing water scarcity or stringent discharge regulations.

These units are integral to a myriad of industrial applications, supporting everything from power generation and chemical processing to manufacturing and data center cooling. Their design prioritizes reliability, low maintenance, and energy efficiency, offering a compelling solution for businesses seeking to optimize their cooling infrastructure while reducing operational costs and environmental impact. The technology behind them represents a mature, yet continuously evolving field, driven by demands for higher performance, greater customization, and seamless integration into sophisticated industrial control systems.

Industry Trends in Industrial Cooling Systems

The industrial cooling sector is undergoing a significant transformation, driven by global megatrends such as sustainability, digitalization, and increasing energy costs. Modern industrial dry coolers are at the forefront of these innovations, evolving to meet stringent performance and environmental criteria. Key trends include:

- Energy Efficiency: A paramount concern, leading to the development of units with advanced fan technologies (e.g., EC fans for variable speed control), optimized coil designs, and intelligent control algorithms that minimize power consumption while maintaining precise temperature control.

- Sustainability and Water Conservation: The inherent advantage of dry coolers—zero water consumption for cooling—positions them as a preferred choice. Further enhancements focus on reducing material usage and extending product lifespan.

- Smart Cooling & IoT Integration: Integration with Building Management Systems (BMS) and Industrial IoT platforms allows for real-time monitoring, predictive maintenance, and remote diagnostics. This proactive approach significantly reduces downtime and optimizes system performance.

- Modular and Scalable Designs: To meet diverse industrial needs, manufacturers are offering modular units that can be easily expanded or reconfigured, providing flexibility for varying load requirements and future expansion plans.

- Noise Reduction: For installations near residential areas or in noise-sensitive environments, low-noise fan options and acoustic enclosures are becoming standard features.

These trends underscore a move towards more intelligent, sustainable, and adaptable cooling solutions, reflecting the growing complexity and demands of modern industrial operations. The emphasis on advanced control systems, such as Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), enables operators to fine-tune performance, track energy usage, and respond quickly to operational changes, thereby maximizing the return on investment for an industrial dry cooler.

Manufacturing Process of an Industrial Dry Cooler

The fabrication of a high-performance industrial dry cooler involves a meticulous process, combining advanced engineering with precision manufacturing techniques to ensure optimal heat exchange capabilities and long-term durability. The core components, materials, and assembly procedures adhere to rigorous industry standards to meet the demanding requirements of industrial environments.

Key Stages in Manufacturing:

- Design and Engineering: Utilizing CAD/CAE software, engineers design the dry cooler based on specific thermal loads, fluid characteristics, ambient conditions, and structural integrity requirements. This includes optimizing coil geometry, fin spacing, fan selection, and structural frame design.

-

Material Selection and Procurement:

- Coil Tubes: Typically seamless copper or stainless steel, chosen for their excellent thermal conductivity and corrosion resistance. Copper (e.g., C12200) is common for water/glycol, while stainless steel (e.g., 304/316L) is used for more aggressive fluids.

- Fins: Aluminum (e.g., 1100 series) with a corrugated or louvered profile for maximum heat transfer surface area. Special coatings (e.g., hydrophilic, epoxy) can be applied for enhanced corrosion resistance.

- Frame & Casing: Galvanized steel, aluminum, or stainless steel (e.g., SS304) sheets are used, often powder-coated for superior weather protection and aesthetic appeal. Components are shaped through CNC bending and laser cutting.

- Fans: Axial fans with high-efficiency blades, often with EC (Electronically Commutated) motors for variable speed control and energy savings. Impellers may be cast aluminum or composite materials.

-

Coil Fabrication:

- Tube Expansion: Copper or stainless steel tubes are mechanically expanded into aluminum fins to create a tight, permanent bond, ensuring efficient thermal contact.

- Bending and Brazing/Welding: Tubes are bent into serpentine shapes, and headers are brazed (for copper) or welded (for stainless steel) to form the complete coil circuit. High-precision welding techniques ensure leak-proof connections.

- Frame Assembly: Structural components, often formed by CNC machining, are assembled using robust fastening techniques (e.g., bolting, welding) to create a sturdy and resilient frame capable of withstanding operational stresses and environmental factors.

- Component Integration: Fans, motors, electrical control panels (PLC, HMI), and sensors are securely mounted onto the frame and wired according to electrical schematics. Piping connections for the process fluid are integrated.

-

Testing and Quality Assurance: Every industrial dry cooler undergoes rigorous testing to ensure performance and reliability.

- Pressure Testing: Coils are hydrostatically or pneumatically tested (e.g., at 30 bar for 24 hours) to verify leak integrity as per ISO 9001 and ANSI standards.

- Performance Testing: Airflow, sound levels, and thermal capacity are tested under simulated operating conditions to confirm compliance with design specifications.

- Electrical Safety Checks: Wiring, grounding, and control systems are checked to meet international electrical safety standards (e.g., CE, UL).

- Finishing and Packaging: Units are cleaned, painted (if applicable), and prepared for shipment. Robust packaging protects the unit during transit.

The typical service life of a well-maintained industrial dry cooler is 15-20 years, a testament to the quality of materials and manufacturing processes. Target industries include petrochemical, metallurgy, power generation, water supply & drainage, and HVAC for large commercial and industrial facilities. Advantages in these scenarios include significant energy savings due to optimized fan operation and the elimination of water treatment costs, as well as superior corrosion resistance from high-grade materials and coatings.

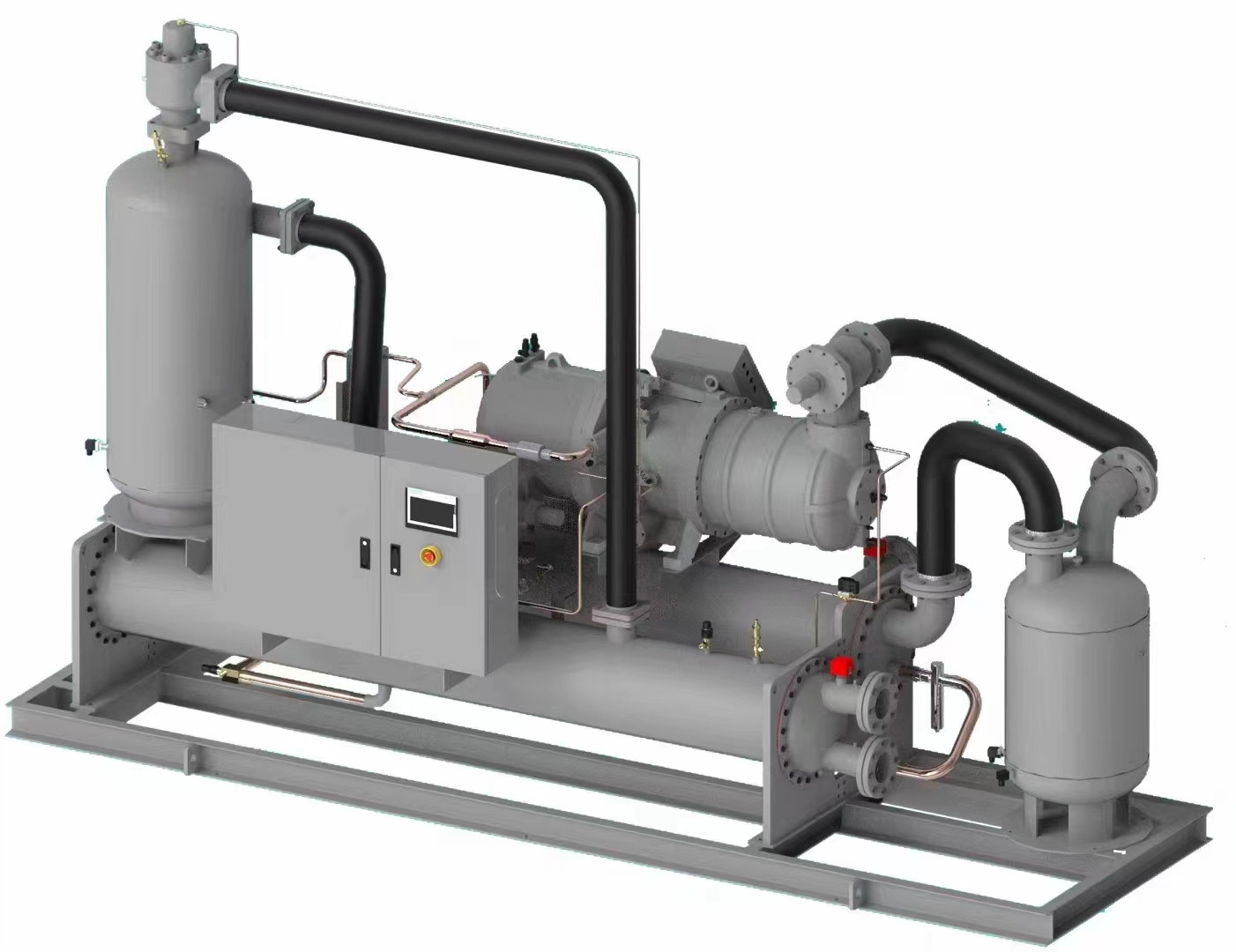

Figure 1: Internal structure of an industrial dry cooler, showcasing coil and fan assembly.

Technical Specifications and Parameters

Understanding the technical specifications of an industrial dry cooler is crucial for proper system integration and performance optimization. These parameters define the unit's capacity, efficiency, and operational limits.

Typical Technical Specifications:

| Parameter | Description | Typical Range / Value |

|---|---|---|

| Cooling Capacity | Amount of heat rejected by the unit. | 50 kW to 2000 kW (single unit) |

| Fluid Inlet Temperature | Temperature of the process fluid entering the cooler. | 25°C to 60°C |

| Fluid Outlet Temperature | Desired temperature of the process fluid leaving the cooler. | 20°C to 50°C (typically 5-10K above ambient) |

| Ambient Air Temperature | Maximum design ambient temperature. | Up to 45°C - 50°C |

| Fluid Flow Rate | Volume of fluid circulated through the cooler. | 10 m³/h to 500 m³/h |

| Fan Type & Quantity | Type of fan (axial, centrifugal) and number of fans. | Axial, 1 to 20+ units |

| Fan Motor Power | Electrical power consumption of fans. | 0.5 kW to 15 kW per fan |

| Noise Level | Sound pressure level at 1m, 10m distance. | 50 dB(A) to 80 dB(A) (standard), |

| Dimensions (L x W x H) | Physical size of the unit. | Varies widely based on capacity |

| Coil Material | Material of tubes and fins. | Copper tubes/Aluminium fins, SS tubes/Aluminium fins |

| Pressure Drop | Fluid pressure loss across the coil. | Typically |

These specifications are crucial for matching the cooler to the specific requirements of the process, ensuring efficient and reliable operation. Factors such as altitude, humidity, and the type of process fluid (e.g., water, glycol mixture, oil) will influence the precise sizing and selection of the industrial dry cooler.

Application Scenarios of Air-Cooled Industrial Chillers

Air cooled industrial chillers and dry coolers are indispensable across a vast spectrum of industrial sectors, providing critical cooling for machinery, processes, and products. Their versatility stems from their ability to handle various thermal loads and integrate into diverse operational environments.

Key Application Areas:

- Plastics Processing: Cooling molds, hydraulic oil, and extrusion lines in injection molding, blow molding, and film extrusion to maintain product quality and cycle times.

- Metal Working: Dissipating heat from cutting fluids, welding equipment, and induction furnaces. Ensures precision machining and extends tool life.

- Chemical & Pharmaceutical Industries: Temperature control for reactors, condensers, solvent recovery, and analytical equipment, crucial for maintaining reaction kinetics and product purity.

- Food & Beverage: Cooling for fermentation processes, product mixing, pasteurization, and storage facilities, maintaining quality and extending shelf life.

- Power Generation: Cooling auxiliary equipment like engine jackets, oil coolers, and generator windings, preventing overheating and ensuring consistent power output.

- Data Centers: Providing cooling for IT infrastructure (servers, racks) to prevent overheating, which is critical for continuous operation and data integrity.

- HVAC & Comfort Cooling: For large commercial buildings, industrial complexes, and district cooling schemes, often as part of a free cooling strategy when ambient temperatures are low.

Figure 2: A robust industrial dry cooler installation serving a manufacturing plant.

In scenarios demanding cooling above ambient temperatures, industrial air chiller units are highly effective. For example, in a plastics injection molding facility, maintaining a precise coolant temperature (e.g., 10-12°C) for mold cooling is paramount. A properly sized dry cooler, often working in tandem with a chiller for lower temperatures or as a standalone unit for higher temperature process cooling, ensures consistent production quality and reduced cycle times. The ability to operate without water consumption makes them especially valuable in regions with strict water usage regulations or where water treatment is costly.

Technical Advantages of Industrial Dry Coolers

The selection of an industrial dry cooler offers numerous technical and operational advantages that contribute to their widespread adoption across industries. These benefits directly impact system efficiency, environmental footprint, and long-term cost of ownership.

- Water Conservation: As non-evaporative systems, dry coolers eliminate water consumption for cooling, a significant advantage over cooling towers, leading to substantial savings in water costs and compliance with environmental regulations. This also eradicates the need for water treatment chemicals and associated discharge permits.

- Reduced Maintenance: Without the scale, corrosion, and biological growth issues associated with water-based systems, dry coolers require considerably less maintenance. This translates to lower operational costs, reduced downtime, and a longer operational lifespan.

- Enhanced Reliability: Simpler operation with fewer moving parts (primarily fans and controls) compared to complex evaporative systems enhances reliability. Modern units feature robust construction materials (e.g., galvanized steel, copper/aluminum coils, EC fans) designed for continuous industrial duty.

- Energy Efficiency (Free Cooling): When ambient temperatures are sufficiently low, dry coolers can provide "free cooling," entirely or partially satisfying the cooling load without engaging a chiller's compressor. This drastically reduces energy consumption, especially in colder climates or during winter months, making them a cost-effective solution for many air cooled industrial chillers applications.

- Environmentally Friendly: Beyond water saving, the absence of chemical water treatment minimizes the discharge of harmful substances into the environment. Many units also utilize refrigerants with low Global Warming Potential (GWP) when integrated with chillers, further reducing their ecological footprint.

- Flexible Installation: Dry coolers are typically compact and can be installed on rooftops, at ground level, or in remote locations, offering flexibility in plant layout and design.

- Corrosion Resistance: Utilizing high-quality materials such as coated aluminum fins, copper or stainless steel tubes, and corrosion-resistant casings ensures durability even in harsh industrial environments.

These advantages collectively contribute to a lower Total Cost of Ownership (TCO) over the lifecycle of the equipment, making an industrial dry cooler a sound investment for industrial cooling requirements.

Vendor Comparison: Choosing the Right Air Cooled Chiller Manufacturer

Selecting the right air cooled chiller manufacturers or industrial dry cooler supplier is a critical decision that impacts long-term operational efficiency and reliability. While many manufacturers offer standard products, discerning the key differentiators between them involves evaluating various factors beyond just the initial purchase price.

Key Comparison Criteria for Industrial Dry Coolers:

| Feature/Criterion | Premium Manufacturer | Standard Manufacturer |

|---|---|---|

| Energy Efficiency (EER/COP) | High EER/COP, often utilizing EC fans, advanced control logic, optimized coil design for superior part-load efficiency. Seasonal Energy Efficiency Ratio (SEER) 4.0+. | Standard EER/COP, AC fans, basic controls. Focus on initial cost. SEER typically 3.0-3.5. |

| Material Quality | SS304/316L frame, seamless copper/SS tubes, epoxy-coated fins, high-grade fan motors (e.g., IE3/IE4 efficiency). | Galvanized steel frame, standard copper tubes, uncoated aluminum fins, basic fan motors. |

| Control System | Advanced PLC with HMI, remote monitoring (IoT), predictive maintenance, BMS integration, Modbus/BACnet protocols. | Basic thermostat/contactor control, limited fault diagnostics. |

| Noise Level | Low-noise EC fans, acoustic enclosures, specialized fan blade designs. Often below 55 dB(A) at 10m. | Standard noise levels, typically 65-75 dB(A) at 10m. |

| Customization Options | Extensive customization for fluid types, pressure ratings, dimensions, special coatings, redundancy, integrated pumping systems. | Limited standard options. |

| Certifications | ISO 9001, CE, ASME, UL/ETL, Eurovent certified performance data. | Basic CE compliance, often self-declared. |

| After-Sales Support & Warranty | Comprehensive warranty (e.g., 2-5 years), global service network, spare parts availability, remote diagnostics. | Standard 1-year warranty, regional support. |

Figure 3: Advanced control panel for an industrial dry cooler, emphasizing smart integration.

For critical industrial processes, investing in a premium industrial dry cooler from a reputable manufacturer like XXColdroom.com offers a better return through superior efficiency, reliability, and support, ultimately leading to lower total cost of ownership and uninterrupted operations.

Customized Solutions for Industrial Cooling

While standard portable industrial chillers and dry coolers meet many common requirements, specific industrial applications often necessitate highly customized cooling solutions. Tailoring a dry cooler to precise operational parameters ensures optimal performance, maximum energy efficiency, and seamless integration into existing infrastructure.

Areas of Customization:

- Coil Configuration: Custom tube materials (e.g., exotic alloys for corrosive fluids), fin types (e.g., coated fins for harsh environments, wide fin spacing for dusty conditions), and circuiting for specific pressure drop and flow rate requirements.

- Fan & Motor Selection: Customized fan diameters, blade designs, and motor types (e.g., explosion-proof motors for hazardous areas, ultra-low noise fans for residential proximity, high-static pressure fans for ducted applications).

- Structural Design: Reinforced frames for seismic zones, specialized mounting arrangements, unique footprints to fit confined spaces, and specific paint finishes or casing materials (e.g., marine-grade aluminum) for extreme weather.

- Control Systems: Integration with proprietary BMS, advanced PLC programming for complex sequencing, remote diagnostic capabilities, custom alarms, and redundant control systems for critical applications.

- Integrated Components: Inclusion of pumps, expansion tanks, filtration systems, or heat exchangers directly mounted on the dry cooler skid, creating a compact, plug-and-play cooling module.

- Fluid Compatibility: Designs optimized for specific process fluids beyond water/glycol, such as oils, coolants, or low-viscosity chemicals, requiring special metallurgy and sealing.

Working with an experienced air cooled chiller manufacturer that offers robust customization capabilities ensures that the dry cooler not only meets current demands but also anticipates future needs, providing a truly bespoke and resilient cooling infrastructure.

Application Case Studies & Customer Feedback

Real-world application demonstrates the tangible benefits and reliability of a well-engineered industrial dry cooler. These case studies highlight effective problem-solving and long-term value for clients across diverse industries.

Case Study 1: Petrochemical Plant Process Cooling

A major petrochemical complex required a reliable and water-efficient solution for cooling its exothermic reactor jackets, operating at a fluid inlet temperature of 55°C. Traditional cooling towers were facing severe water scarcity issues and high chemical treatment costs. We engineered a custom-designed industrial dry cooler system with 1.5 MW capacity, utilizing stainless steel tubes for corrosion resistance against the process fluid and marine-grade aluminum fins for enhanced durability in the coastal environment. Integrated EC fans with intelligent control allowed for precise temperature regulation and significant energy savings during cooler ambient conditions. The system achieved a 30% reduction in energy consumption compared to their previous setup and eliminated over 10,000 m³/year of water usage, demonstrating superior operational efficiency and environmental compliance. Customer feedback highlighted the system's robust performance and minimal maintenance requirements.

Case Study 2: Data Center Free Cooling Integration

A leading data center operator sought to improve the energy efficiency of its cooling infrastructure, specifically looking to reduce the run-time of its conventional chillers. Our solution involved integrating a series of high-capacity industrial dry cooler units into their existing chiller plant, operating in a "free cooling" mode. During colder months (when ambient temperatures drop below a setpoint, e.g., 10°C), the dry coolers take over the primary cooling load, circulating chilled water directly from the ambient air to the data center's Computer Room Air Handlers (CRAHs). The chillers only engage when the ambient temperature exceeds this threshold. This hybrid approach led to an estimated 40% reduction in annual chiller compressor energy consumption, resulting in significant cost savings and a reduced carbon footprint. The client praised the seamless integration with their existing BMS and the intuitive control interface.

Figure 4: Industrial dry cooler system implemented for large-scale facility cooling.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between an industrial dry cooler and a cooling tower?

A1: An industrial dry cooler rejects heat directly to the ambient air using sensible heat transfer, similar to a car radiator, without consuming water for cooling. A cooling tower utilizes evaporative cooling, which involves evaporating a small portion of the circulating water to achieve cooling, thus consuming water and requiring chemical treatment.

Q2: Can a dry cooler achieve temperatures below ambient?

A2: No, a standard industrial dry cooler can only cool a fluid to a temperature approaching the ambient air temperature. It cannot cool below ambient. For temperatures below ambient, an industrial air chiller (which uses a refrigeration cycle) is required, often working in conjunction with a dry cooler for pre-cooling or free cooling during suitable conditions.

Q3: What maintenance is required for an industrial dry cooler?

A3: Maintenance is relatively low. Key tasks include periodic cleaning of the coil fins to ensure optimal airflow and heat transfer, inspection of fans and motors for wear, and checking electrical connections. Unlike cooling towers, there's no need for water treatment, basin cleaning, or descaling.

Q4: What is the typical lead time for an industrial dry cooler?

A4: Lead times vary based on customization and component availability. For standard models, lead time can range from 4 to 8 weeks. Highly customized solutions may require 10 to 16 weeks for design, manufacturing, and testing.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment:

Our commitment to efficient project delivery ensures that your industrial dry cooler is delivered on schedule. Standard units typically have a lead time of 6-8 weeks from order confirmation to shipment, depending on specifications and current production load. For custom-engineered solutions, the lead time will be detailed in the project proposal, typically ranging from 10-16 weeks to accommodate comprehensive design, material sourcing, specialized manufacturing, and rigorous testing phases. We maintain transparent communication throughout the fulfillment process, providing regular updates and projected delivery milestones.

Warranty Commitments:

We stand behind the quality and reliability of our air cooled industrial chillers and dry coolers with comprehensive warranty programs. All new industrial dry coolers come with a standard 12-month warranty on parts and labor, effective from the date of commissioning or 18 months from shipment, whichever comes first. Extended warranty options, covering up to 3-5 years, are available for enhanced peace of mind, particularly for critical industrial applications. Our warranty covers defects in materials and workmanship, ensuring your investment is protected.

Customer Support:

Exceptional customer support is a cornerstone of our service. Our dedicated team of technical experts and service engineers is available to provide:

- Pre-Sales Consultation: Expert guidance on system sizing, selection, and customization to meet your specific industrial cooling needs.

- Installation & Commissioning Support: Assistance and supervision to ensure proper installation and optimal commissioning of your dry cooler.

- After-Sales Technical Assistance: Prompt troubleshooting, diagnostics, and technical advice available via phone, email, and remote access.

- Spare Parts Availability: A readily available inventory of genuine spare parts to minimize downtime and ensure longevity.

- Preventative Maintenance Programs: Tailored service contracts designed to maximize efficiency and extend the lifespan of your cooling equipment.

Our commitment extends throughout the lifecycle of your industrial dry cooler, ensuring continuous performance and customer satisfaction.

References

- ASHRAE Handbook—HVAC Systems and Equipment. American Society of Heating, Refrigerating and Air-Conditioning Engineers, 2020.

- European Committee for Standardization. EN 378-1:2016 Refrigerating systems and heat pumps—Safety and environmental requirements. CEN, 2016.

- International Organization for Standardization. ISO 9001:2015 Quality management systems—Requirements. ISO, 2015.

- U.S. Department of Energy. "Energy Savers: Industrial Cooling Towers & Heat Rejection Systems." Energy.gov.

- Process Heating Magazine. "Understanding Dry Coolers for Industrial Applications." BNP Media, 2023.