oem dx air cooled condensing unit

Understanding OEM DX Air Cooled Condensing Units

In the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems, the efficiency and reliability of cooling solutions are paramount to ensuring comfort and safety in various environments, such as commercial buildings, industrial facilities, and residential homes. One of the standout innovations in this field is the OEM DX (Direct Expansion) air-cooled condensing unit. This article explores what these units are, their benefits, and their applications.

What is an OEM DX Air Cooled Condensing Unit?

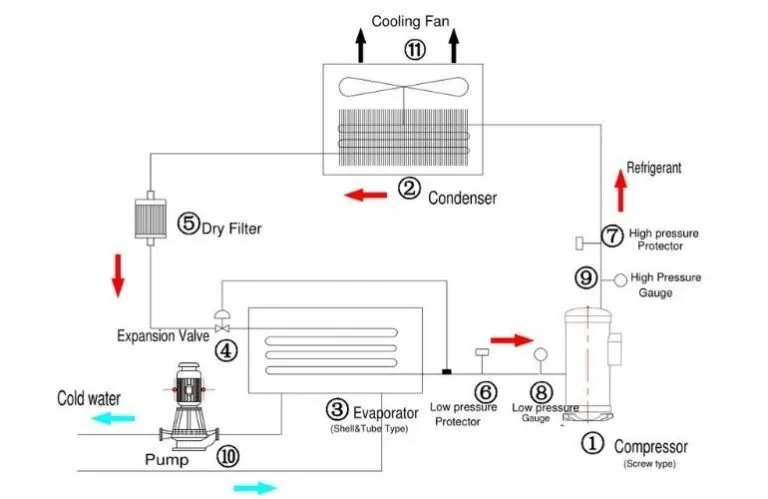

An OEM DX air-cooled condensing unit is a type of refrigeration equipment designed to remove heat from a space by using refrigerants. OEM stands for Original Equipment Manufacturer, which implies that these units are produced for integration into other systems or for resale under a brand name. The DX refers to the direct expansion cooling method, where the refrigerant evaporates inside the cooling coils located within the space that needs to be cooled.

These units use fans to draw in ambient air, which then flows over the coils filled with refrigerant. As the refrigerant evaporates, it absorbs heat from the air, thereby cooling it. This cooled air is then circulated back into the environment, creating a comfortable indoor atmosphere.

Benefits of OEM DX Air Cooled Condensing Units

1. Energy Efficiency One of the primary advantages of OEM DX air-cooled condensing units is their energy efficiency. They are designed to provide optimal cooling performance while consuming minimal energy, which can lead to significant cost savings for businesses and homeowners alike. Many models also feature variable speed fans, further enhancing their energy efficiency.

2. Easy Installation These units are generally easier to install compared to water-cooled systems, which require a complex network of pipes and cooling towers. The simplicity of air-cooled systems means they can be installed quickly and with minimal disruption to existing operations.

3. Versatility OEM DX units can be used in a wide variety of applications, from small businesses and restaurants to large industrial facilities. They can be configured to meet specific cooling needs, making them a versatile choice for many different environments.

oem dx air cooled condensing unit

4. Low Maintenance With fewer components than traditional cooling systems, OEM DX air-cooled condensing units typically require less maintenance. Regular cleaning of coils and checking refrigerant levels are usually sufficient to keep the units running efficiently, which reduces downtime and maintenance costs.

5. Environmentally Friendly Many manufacturers are now focusing on producing units that use refrigerants with a lower global warming potential (GWP), making them more environmentally friendly. This commitment to sustainability is increasingly important to both consumers and industry regulators.

Applications of OEM DX Air Cooled Condensing Units

OEM DX air-cooled condensing units are widely used in a variety of industries due to their flexibility and efficiency. Common applications include

- Commercial Refrigeration Grocery stores, convenience stores, and restaurants use these units for walk-in coolers and freezers to store perishable goods. - Industrial Cooling Factories and manufacturing facilities often rely on these units for process cooling and temperature control in production environments. - HVAC Systems Many HVAC systems in office buildings and retail environments incorporate these units to provide comfortable indoor climates.

Conclusion

The OEM DX air-cooled condensing unit represents a modern solution to effective cooling and refrigeration. With their energy efficiency, ease of installation, and versatility, they are well-suited for a wide range of applications. As businesses increasingly prioritize sustainability and cost-effectiveness, these units will likely continue to gain traction in the HVAC market.

In summary, understanding the operation and advantages of OEM DX air-cooled condensing units can help organizations make informed decisions about their cooling solutions, ensuring a comfortable and efficient environment for occupants while also being environmentally responsible. As technology continues to advance, we can expect further innovations in this field, leading to even greater efficiencies and capabilities in cooling systems.