cover for condensing unit factories

The Importance of Covering Condensing Unit Factories Ensuring Safety, Efficiency, and Longevity

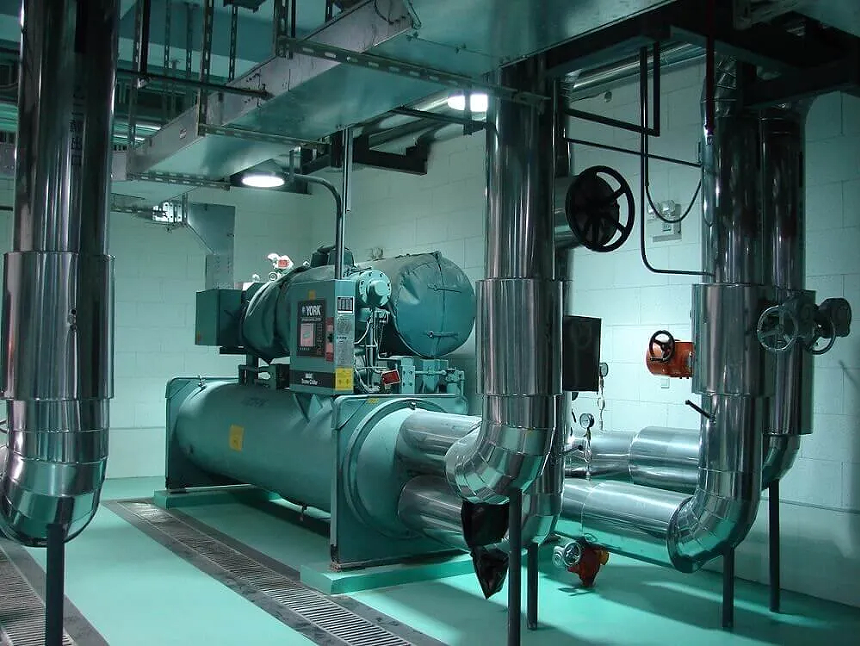

In the realm of refrigeration and air conditioning, condensing units play a crucial role in maintaining optimal temperatures across various applications, from residential buildings to large industrial facilities. As the heart of cooling systems, these units require not only efficient operation but also protection from environmental factors. This is where the concept of covering condensing unit factories comes into play. By implementing effective cover solutions, manufacturers can enhance the durability, safety, and energy efficiency of their condensing units.

Understanding Condensing Units

Before delving into the benefits of covering condensing unit factories, it's essential to understand what these units are and how they operate. A condensing unit comprises a compressor, condenser coil, and fan, all working together to expel heat and circulate refrigerant. Given their exposure to outdoor elements, these units can face numerous challenges, such as extreme temperatures, moisture, debris, and other contaminants. Over time, these external factors can lead to decreased efficiency and even failures, necessitating maintenance and costly repairs.

Protecting Against Environmental Elements

Covering condensing unit factories serves as a protective measure against environmental hazards. For instance, harsh weather conditions such as heavy rainfall, snowfall, and intense sunlight can adversely affect the performance of condensing units. A robust cover helps shield the units from rain and snow build-up, which can lead to corrosion and mechanical failures. Similarly, UV rays from the sun can degrade the materials of the unit over time, reducing its lifespan. By using quality covers, manufacturers can ensure that their condensing units remain in optimal condition for years to come.

Enhancing Energy Efficiency

cover for condensing unit factories

Another significant advantage of covering condensing unit factories is enhanced energy efficiency. When exposed to dirt and debris, the coils of a condensing unit can become clogged, impeding airflow and leading to inefficient operation. This inefficiency often results in increased energy consumption, which can skyrocket operating costs. Effective covers can keep out debris, allowing the unit to function smoothly and maintain an ideal energy use profile. Moreover, by preventing excessive heat gain during the hottest months, covers can contribute to lowered energy needs for cooling, further promoting energy savings.

Safety Considerations

Safety is paramount in any manufacturing facility, including those responsible for condensing unit production. Covers can contribute to a safer working environment by reducing the risk of accidents. Uncovered units may present slipping hazards due to condensation or accumulation of snow and ice around the area. Moreover, secure coverings can minimize the risk of unauthorized access to sensitive machinery, ensuring that only trained personnel operate the units. This added layer of protection can also prevent potential workplace injuries and related liabilities.

Longevity and Maintenance

Investing in protective covers for condensing unit factories can significantly extend the lifespan of the equipment. Regular wear and tear due to environmental exposure can lead to premature deterioration, resulting in higher replacement costs. By minimizing such exposure through the use of quality covers, manufacturers can greatly reduce maintenance frequency and prolong the life of their condensing units. Additionally, covered units are often easier to service, as they remain cleaner and require less immediate attention, allowing technicians to perform routine checks and maintenance more efficiently.

Conclusion

In conclusion, the practice of covering condensing unit factories is a pivotal aspect of ensuring that these essential cooling systems operate effectively and endure the test of time. By protecting against environmental threats, enhancing energy efficiency, improving safety conditions, and prolonging the lifespan of the units, manufacturers can realize considerable benefits. As the demand for energy-efficient, sustainable refrigeration solutions continues to grow, investing in cover solutions will be key to maintaining competitive advantages in the industry. With these protective measures in place, condensing unit factories can thrive in an ever-evolving market, consistently delivering reliable performance and peace of mind to consumers.