custom cold storage racking

Custom Cold Storage Racking Optimizing Efficiency in Cold Storage Facilities

In today’s world of trade and commerce, the food and pharmaceutical industries face an increasing demand for efficient cold storage solutions. Custom cold storage racking systems have emerged as a pivotal aspect of warehouse infrastructure, ensuring that temperature-sensitive products are stored securely while maximizing space and accessibility. This article explores the fundamental components, benefits, and considerations involved in designing custom cold storage racking systems.

Understanding Cold Storage Racking

Cold storage racking refers to specialized shelving and storage systems designed for environments where temperature control is crucial. Such facilities are used to store perishable goods like fruits, vegetables, dairy products, and pharmaceuticals, which require consistent temperatures to maintain freshness and efficacy. Custom racking solutions are tailored to the specific needs of each facility, taking into account factors such as temperature requirements, inventory types, and space constraints.

Benefits of Custom Cold Storage Racking

1. Space Optimization One of the primary advantages of custom cold storage racking is the ability to optimize space effectively. Businesses can design racking systems that utilize vertical space, maximizing storage capacity without increasing the physical footprint of the facility. This becomes increasingly important as consumer demand rises and space becomes at a premium.

2. Enhanced Accessibility Custom racking systems can be designed to improve the accessibility of stored items, enabling easy retrieval. This is especially critical in cold storage environments where workers need to move swiftly to minimize exposure to low temperatures. By organizing products based on their turnover rates and implementing features such as sliding shelves or pull-out racks, businesses can enhance workflow efficiency.

3. Improved Inventory Management Effective inventory management is crucial in cold storage operations. Custom racking allows businesses to implement systems that facilitate better tracking and monitoring of inventory levels. This can lead to reduced waste due to spoilage, as items are rotated and stored in a manner that prioritizes products nearing expiration.

4. Compliance with Regulations Many industries, particularly food and pharmaceuticals, are governed by strict regulations regarding storage conditions. Custom cold storage racking can be designed to meet these compliance standards, incorporating features such as temperature sensors and monitoring systems that ensure product safety.

custom cold storage racking

5. Scalability As businesses grow, so do their storage needs. Custom racking solutions can be designed with scalability in mind, allowing facilities to adapt their storage systems over time without the need for a complete redesign. This flexibility can save businesses money in the long run and support their growth trajectories.

Key Considerations in Designing Custom Cold Storage Racking

When designing custom cold storage racking systems, several factors must be considered

1. Temperature Zones Different products may require specific temperature zones (e.g., frozen, chilled, or ambient). It is essential to categorize inventory correctly to ensure optimal storage conditions. Custom racking systems can be designed to incorporate varied temperature zones within the same facility.

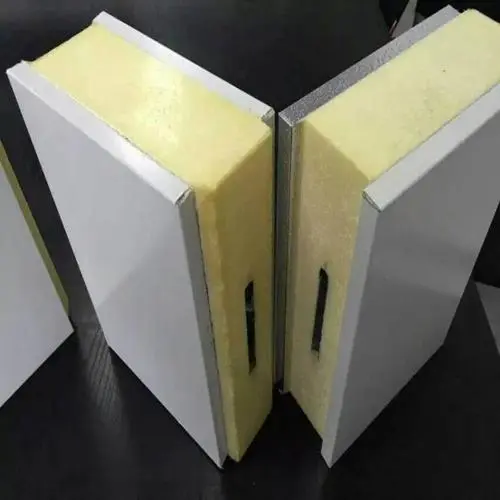

2. Material Selection The materials used in constructing cold storage racking systems must be able to withstand harsh conditions, including low temperatures and humidity. Stainless steel and aluminum are often preferred due to their durability and resistance to corrosion.

3. Load Capacity Each racking unit must be designed to support the weight of the stored items. Businesses should calculate load capacities based on the type and volume of products they plan to store to avoid structural failures.

4. Future-Proofing With technology and industry practices evolving rapidly, it’s vital for businesses to consider future needs when investing in custom racking systems. Integrating features that allow for technological upgrades, such as automated inventory systems or advanced temperature monitoring, can be highly beneficial.

Conclusion

Custom cold storage racking systems are essential for businesses that rely on the storage of temperature-sensitive products. By optimizing space, enhancing accessibility, and improving inventory management while adhering to regulatory standards, these tailored solutions can significantly improve operational efficiency. As the market continues to grow, investing in custom cold storage racking will not only support current demands but also prepare businesses for future challenges. Embracing these innovations is crucial for staying competitive in an ever-evolving marketplace.