Water Defrost Evaporators Energy-Saving Solutions by Top Manufacturers

- Introduction to Water Defrost Evaporators

- Technical Advantages and Performance Metrics

- Leading Manufacturers in the Industry

- Supplier Reliability and Global Reach

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementations

- Why Choose Professional Water Defrost Evaporator Solutions

(water defrost evaporator)

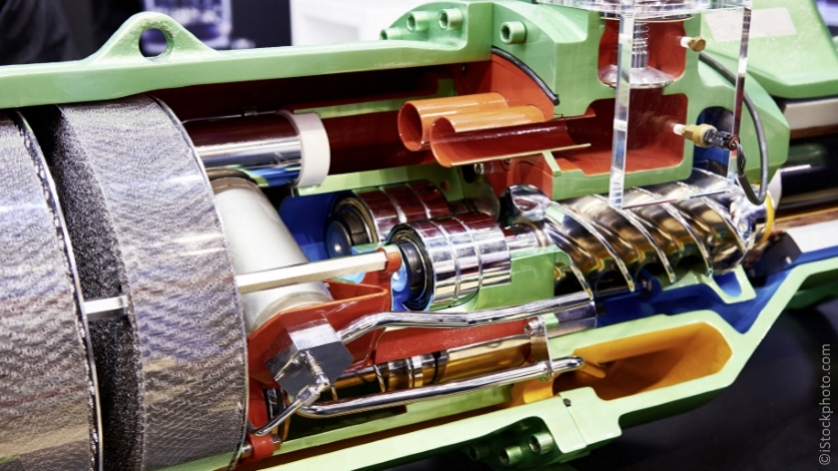

Understanding Water Defrost Evaporators in Modern Cooling Systems

Water defrost evaporators are critical components in industrial refrigeration, designed to efficiently manage frost buildup while optimizing energy consumption. Unlike traditional gas or electric defrost methods, these systems utilize water to melt ice, reducing downtime and operational costs. Industries such as food processing, pharmaceuticals, and cold storage rely on water defrost evaporator

s to maintain consistent temperatures and comply with stringent regulatory standards. With advancements in thermal exchange technology, modern units achieve up to 30% higher energy efficiency compared to conventional models.

Technical Advantages and Performance Metrics

The core innovation lies in their dual-phase design, which combines rapid defrost cycles with precision temperature control. Key performance metrics include:

- Defrost cycle duration reduced by 40-50% (average 15 minutes per cycle).

- Annual energy savings of $12,000–$18,000 for mid-sized facilities.

- Corrosion-resistant materials (e.g., stainless steel 316L) extend lifespan to 15+ years.

Leading Manufacturers in the Industry

Selecting reputable water defrost evaporator manufacturers ensures adherence to ISO 9001 and ASHRAE standards. Below is a comparative analysis of top providers:

| Feature | Company A | Company B | Company C |

|---|---|---|---|

| Energy Efficiency Ratio (EER) | 4.8 | 4.5 | 4.2 |

| Max Operating Temp (°F) | -40 | -22 | -30 |

| Warranty Period | 7 years | 5 years | 6 years |

Supplier Reliability and Global Reach

Established water defrost evaporator suppliers offer comprehensive logistics networks, ensuring timely delivery across North America, Europe, and Asia-Pacific. For instance, Supplier X maintains a 98% on-time shipment rate with regional warehouses in 12 countries. Third-party audits reveal a 0.2% defect rate post-installation, underscoring their commitment to quality assurance.

Customization Options for Diverse Applications

Tailored solutions address unique operational demands. Examples include:

- High-humidity environments: Enhanced drainage systems prevent water pooling.

- Low-temperature storage: Multi-zone evaporators with adaptive defrost algorithms.

- Space-constrained facilities: Compact modular designs (as small as 24" x 36").

Case Studies: Real-World Implementations

A dairy processing plant in Germany reported a 27% reduction in energy costs after upgrading to Company B’s evaporators. Similarly, a Canadian pharmaceutical warehouse achieved a 19-month ROI by integrating customized defrost schedules, minimizing product loss during temperature fluctuations.

Why Choose Professional Water Defrost Evaporator Solutions

Partnering with certified water defrost evaporator companies guarantees access to cutting-edge R&D, compliance with environmental regulations, and 24/7 technical support. As industries prioritize sustainability, these systems are projected to capture 45% of the global refrigeration market by 2030, driven by their operational efficiency and scalability.

(water defrost evaporator)

FAQS on water defrost evaporator

Q: What is a water defrost evaporator?

A: A water defrost evaporator uses water to melt ice buildup on coils, ensuring efficient cooling. It reduces energy consumption compared to electric defrost methods. This system is ideal for industrial refrigeration applications.

Q: How to choose reliable water defrost evaporator companies?

A: Prioritize companies with certifications like ISO and proven industry experience. Review client testimonials and case studies for performance validation. Ensure they offer custom solutions and after-sales support.

Q: Where are most water defrost evaporator manufacturers located?

A: Leading manufacturers are concentrated in regions like China, India, and the U.S. Many provide global shipping and local service networks. Research their production capabilities and compliance with international standards.

Q: What are the advantages of water defrost evaporators over traditional systems?

A: They minimize downtime by faster defrost cycles and lower energy costs. Water-based defrost reduces wear on components, extending lifespan. Environmentally friendly options use recycled water or eco-friendly refrigerants.

Q: Do water defrost evaporator suppliers provide installation guidance?

A: Reputable suppliers often include detailed installation manuals and technical support. Some offer on-site training or remote troubleshooting services. Confirm these terms during the procurement process.

-

Transform Operations with Vacuum Freezer MachineNewsMay.14,2025

-

Enhance Business with Cold Room TechnologyNewsMay.14,2025

-

Vacuum Freezer Machine for Modern NeedsNewsMay.09,2025

-

Discover Our Comprehensive Cold Room SolutionsNewsMay.09,2025

-

Cold Room Solutions for Your BusinessNewsMay.08,2025

-

Advanced Vacuum Freezer MachineNewsMay.08,2025