High Capacity 300 lb Ice Machine Manufacturing Solutions for Your Business Needs

The Manufacturing Process of 300% Ice Machines Innovations and Standards

In a world where efficiency and performance are paramount, the demand for high-quality ice machines has surged. One of the noteworthy innovations in this sector is the 300% ice machine, a robust apparatus designed to produce ice at an extraordinary rate. This article delves into the manufacturing processes of these machines, the technology involved, and the standards they must meet to ensure reliability and efficiency.

Understanding the 300% Ice Machine

A 300% ice machine refers to equipment engineered to generate three times more ice than standard machines within the same timeframe. This is particularly beneficial for industries that require large volumes of ice, such as restaurants, bars, hospitals, and even industrial applications. The increased production capacity not only improves operational efficiency but also provides businesses with a competitive edge.

The Manufacturing Process

The manufacturing of 300% ice machines involves several steps, each meticulously designed to ensure durability, efficiency, and reliability

.1. Design and Engineering Before production begins, a detailed design phase takes place. Engineers utilize advanced software to create blueprints that emphasize optimal airflow, efficient water circulation, and minimized energy consumption. The designs are tested through simulations to ensure they can withstand various operational conditions.

2. Material Selection High-quality materials are crucial for creating a durable ice machine. Stainless steel is commonly used for the exterior due to its resistance to corrosion and ease of cleaning. Other components, such as the evaporator coils and compressor, are also made from materials specifically chosen for their thermal efficiency and longevity.

3. Prototyping Once the design is finalized and materials selected, prototypes of the ice machines are built. This stage is essential for testing the functionality, efficiency, and safety of the machine. Feedback from initial testing leads to adjustments that are made to optimize performance.

4. Production Line Setup After successful prototyping, the production line is established. This includes setting up assembly stations equipped with the necessary tools and machinery. A well-organized production line enhances efficiency and minimizes the risk of errors, ultimately leading to better-quality machines.

300 lb ice machine factory

5. Assembly The assembly process involves integrating all components – from the refrigeration system to the control panel. Skilled technicians ensure that every part is fitted correctly and securely. Quality checks are performed at each stage to monitor for defects.

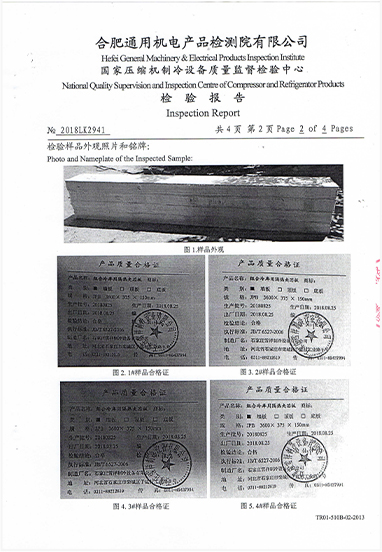

6. Testing and Quality Assurance Once assembled, each ice machine undergoes rigorous testing to evaluate its ice production capacity, energy consumption, and overall performance. Safety protocols are also examined to ensure the machines comply with industry regulations. This testing phase is critical in verifying that each unit meets the brand's high standards before it can be sold.

7. Packaging and Distribution After passing quality assurance, the ice machines are carefully packaged to prevent damage during transportation. Efficient distribution channels are established to ensure that the machines reach customers promptly.

Innovations in Technology

The development of 300% ice machines has been driven by technological advancements. Modern ice machines incorporate features such as smart controls, which allow users to monitor and manage operations remotely. Energy efficiency has also become a focus, with many manufacturers implementing eco-friendly refrigerants and energy-saving technologies that significantly reduce operational costs.

Compliance with Industry Standards

To maintain a competitive edge, manufacturers must adhere to strict industry standards. Safety certifications such as NSF International and Underwriters Laboratories (UL) ensure that the machines are safe for commercial use and meet sanitation requirements. Additionally, energy efficiency ratings help consumers choose machines that align with their work practices and environmental goals.

Conclusion

The production of 300% ice machines exemplifies the intersection of innovation, efficiency, and quality in manufacturing. As the demand for high-capacity ice production continues to grow, manufacturers will need to keep evolving their designs and processes. With a commitment to quality and sustainability, the future of ice machine manufacturing looks promising, promising to make significant contributions to industries reliant on efficient ice production. Whether for commercial kitchens or large events, the 300% ice machine is set to become a staple in the arsenal of businesses striving for excellence in service and operations.