About cold storage evaporator

D type series air cooler (also known as chiller) is suitable for various cold storage cooling equipment, has a compact structure, light weight, does not take up the use of cold storage area, the temperature of the library uniformity, efficiency and other advantages, so that the library of food quickly cooled down, and greatly improve the freshness of the stored food.

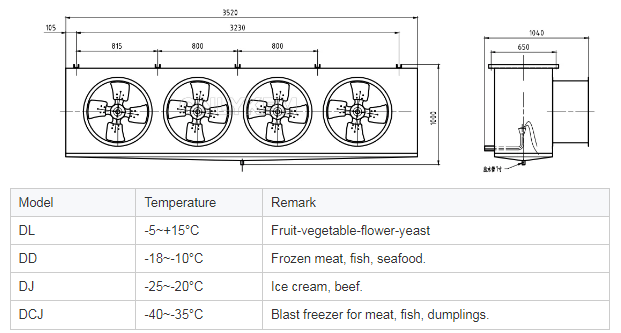

There are three types of DL, DD and DJ chillers in D. DL type is suitable for the cold storage with the temperature of 0℃, such as fruits and vegetables, etc. DD type is suitable for the cold storage with the temperature of -18℃, such as meat, fish and other frozen food for refrigeration, etc. DJ type is suitable for the freezing of fresh meat or fish in the cold storage with the temperature of -25℃ or -25℃ or below.

- Inspection before installation of air cooler

- Appearance inspection;

(1) After unpacking, check whether the connecting parts are loose and whether the air cooler is damaged or deformed. (2) Check whether the blades of the axial flow fan are firmly installed and whether the blades and the protective cover collide. 2. The air coolers are pressurized with nitrogen before leaving the factory. The return air header of the air cooler is equipped with a pressure-maintaining joint. Users should unscrew the sealing cap before installing the air cooler and press the valve core with their hands. If there is air flow sound, it means the sealing is good and you can use it with confidence. If there is no air flow sound, it means the evaporator is leaking and should be checked before use.

- Installation of air cooler

- The D-type Freon ceiling-mounted air cooler can be hoisted on the inner panel of the warehouse with 4, 6, 8 or 10 long bolts.

- The distance between the ceiling-mounted air cooler and the wall should be maintained at 350-1000mm (see picture) to facilitate air circulation and maintenance in the cold storage.

- The ceiling-mounted air cooler should be level after installation.

- The drain pipe of the air cooler leading to the outside of the cold storage should have a certain slope to allow the defrost water to drain out of the cold storage smoothly. The connecting pipe outside the cold storage should be bent into a U-shaped pipe to ensure a certain liquid seal to prevent hot air outside the cold storage. Enter the cold storage. (see picture)

- Appropriate measures should be taken to prevent the defrost water in the drain pipes in the cold storage from freezing during the drainage process.

- When installing the expansion valve, the temperature sensing package must be tied tightly to the upper part of the horizontal air return pipe and ensure good contact with the return air pipe. The outside of the return air pipe should be insulated to prevent the temperature sensing package from being affected by the storage temperature.

- The air outlet of the air cooler should be away from beams or columns to avoid affecting the air supply range.

- The connection outlets between the fan and the outside of the cold storage (liquid inlet and outlet pipes, defrost water pipes, etc.) must be sealed everywhere.