Jun . 14, 2024 06:29

Back to list

Air conditioning manufacturer specializing in chiller units

Chiller Unit Air Conditioning Manufacturers A Key Pillar in Modern Comfort Systems

In the realm of modern HVAC (Heating, Ventilation, and Air Conditioning) technology, chiller unit air conditioning manufacturers play an indispensable role. These specialized companies design, develop, and produce state-of-the-art cooling systems that cater to various industrial, commercial, and residential applications. With their advanced engineering and innovative designs, they ensure efficient temperature control and optimal energy utilization.

A chiller unit, at its core, is a system that removes heat from a liquid coolant, which is then used to cool air or other substances. In air conditioning systems, chillers are crucial components, particularly in large-scale facilities such as hospitals, data centers, malls, and manufacturing plants where substantial cooling capacity is required. The efficiency and reliability of these units directly impact the overall performance and energy consumption of the entire cooling system.

Major manufacturers in this field, like Carrier, Daikin, Trane, and Johnson Controls, are known for their commitment to quality and innovation. They invest heavily in research and development to create chillers that are not only energy-efficient but also environmentally friendly. Many of these manufacturers now offer chillers with advanced features like variable frequency drives, magnetic bearings, and integrated digital controls, all aimed at enhancing performance and reducing operational costs.

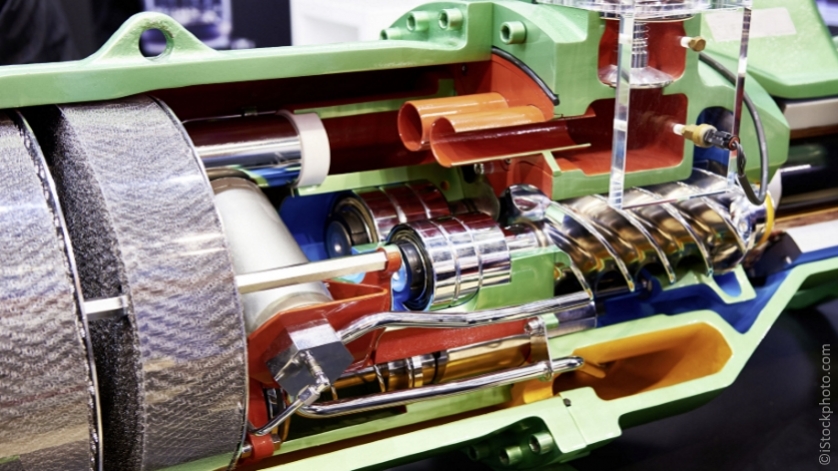

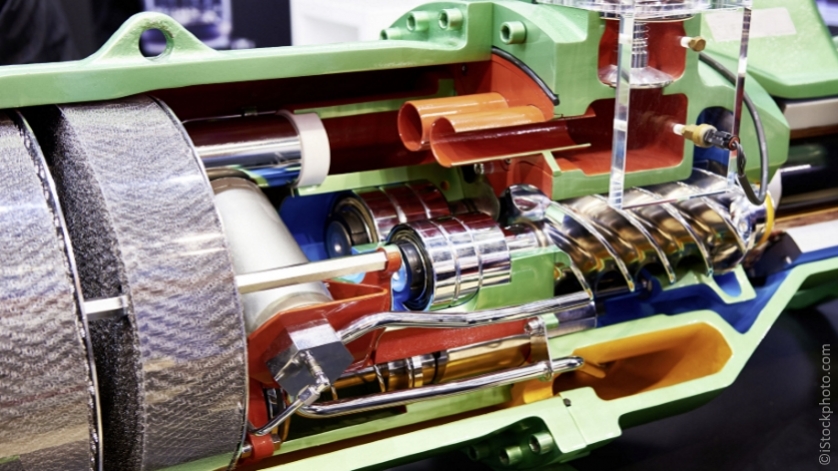

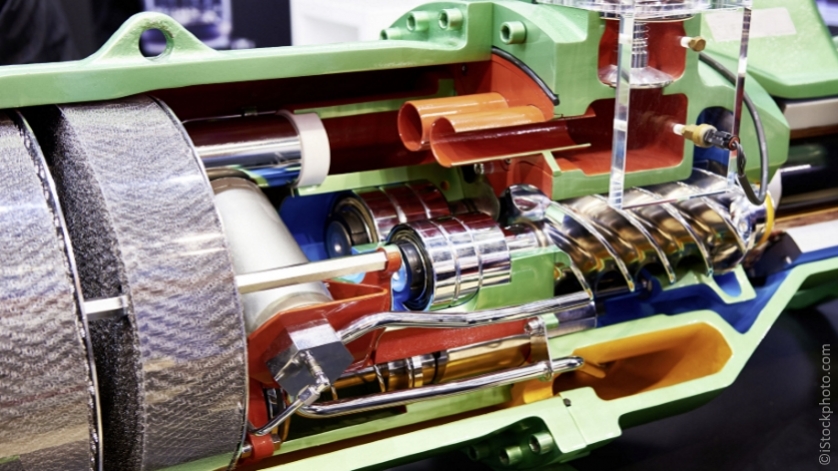

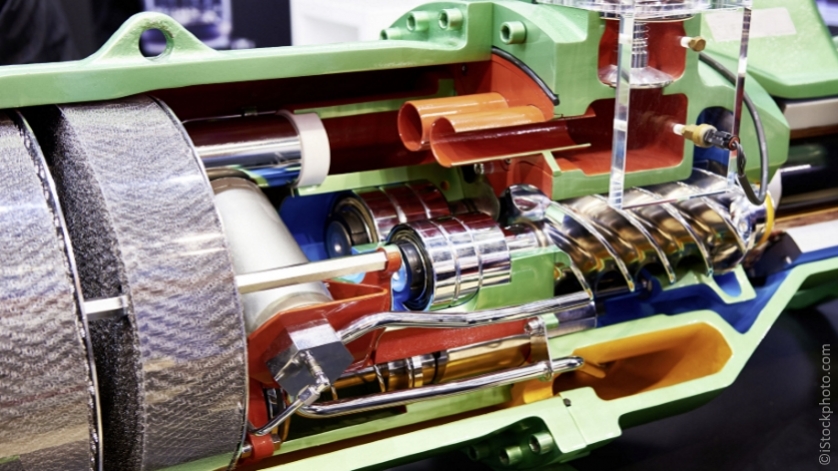

The manufacturing process for chiller units involves a series of complex steps. It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller

It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller chiller unit air conditioning manufacturer. Each component is meticulously tested before assembly to ensure durability and optimal functionality. Once assembled, the entire unit undergoes rigorous testing to guarantee it meets the manufacturer's stringent performance standards.

Moreover, these manufacturers also provide comprehensive services, including installation, maintenance, and repair, ensuring their products function smoothly throughout their lifecycle. They often collaborate with contractors and engineers to design customized solutions tailored to specific customer needs, whether it's a small office building or a massive industrial plant.

Chiller unit air conditioning manufacturers are constantly evolving to meet the changing demands of the industry. As the world shifts towards renewable energy and sustainable practices, manufacturers are incorporating green technologies into their products. For instance, some now produce chillers that use natural refrigerants, such as ammonia or carbon dioxide, which have significantly lower global warming potential than traditional refrigerants.

In conclusion, chiller unit air conditioning manufacturers are integral to the HVAC industry, driving advancements in cooling technology and contributing to a more comfortable and energy-efficient built environment. Their dedication to innovation, quality, and sustainability ensures that these essential systems continue to evolve, meeting the diverse and evolving needs of our society.

chiller unit air conditioning manufacturer. Each component is meticulously tested before assembly to ensure durability and optimal functionality. Once assembled, the entire unit undergoes rigorous testing to guarantee it meets the manufacturer's stringent performance standards.

Moreover, these manufacturers also provide comprehensive services, including installation, maintenance, and repair, ensuring their products function smoothly throughout their lifecycle. They often collaborate with contractors and engineers to design customized solutions tailored to specific customer needs, whether it's a small office building or a massive industrial plant.

Chiller unit air conditioning manufacturers are constantly evolving to meet the changing demands of the industry. As the world shifts towards renewable energy and sustainable practices, manufacturers are incorporating green technologies into their products. For instance, some now produce chillers that use natural refrigerants, such as ammonia or carbon dioxide, which have significantly lower global warming potential than traditional refrigerants.

In conclusion, chiller unit air conditioning manufacturers are integral to the HVAC industry, driving advancements in cooling technology and contributing to a more comfortable and energy-efficient built environment. Their dedication to innovation, quality, and sustainability ensures that these essential systems continue to evolve, meeting the diverse and evolving needs of our society.

It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller

It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller It starts with the selection of high-quality materials, followed by precision engineering to construct the evaporator, compressor, condenser, and expansion valve – the main components of a chiller chiller unit air conditioning manufacturer. Each component is meticulously tested before assembly to ensure durability and optimal functionality. Once assembled, the entire unit undergoes rigorous testing to guarantee it meets the manufacturer's stringent performance standards.

Moreover, these manufacturers also provide comprehensive services, including installation, maintenance, and repair, ensuring their products function smoothly throughout their lifecycle. They often collaborate with contractors and engineers to design customized solutions tailored to specific customer needs, whether it's a small office building or a massive industrial plant.

Chiller unit air conditioning manufacturers are constantly evolving to meet the changing demands of the industry. As the world shifts towards renewable energy and sustainable practices, manufacturers are incorporating green technologies into their products. For instance, some now produce chillers that use natural refrigerants, such as ammonia or carbon dioxide, which have significantly lower global warming potential than traditional refrigerants.

In conclusion, chiller unit air conditioning manufacturers are integral to the HVAC industry, driving advancements in cooling technology and contributing to a more comfortable and energy-efficient built environment. Their dedication to innovation, quality, and sustainability ensures that these essential systems continue to evolve, meeting the diverse and evolving needs of our society.

chiller unit air conditioning manufacturer. Each component is meticulously tested before assembly to ensure durability and optimal functionality. Once assembled, the entire unit undergoes rigorous testing to guarantee it meets the manufacturer's stringent performance standards.

Moreover, these manufacturers also provide comprehensive services, including installation, maintenance, and repair, ensuring their products function smoothly throughout their lifecycle. They often collaborate with contractors and engineers to design customized solutions tailored to specific customer needs, whether it's a small office building or a massive industrial plant.

Chiller unit air conditioning manufacturers are constantly evolving to meet the changing demands of the industry. As the world shifts towards renewable energy and sustainable practices, manufacturers are incorporating green technologies into their products. For instance, some now produce chillers that use natural refrigerants, such as ammonia or carbon dioxide, which have significantly lower global warming potential than traditional refrigerants.

In conclusion, chiller unit air conditioning manufacturers are integral to the HVAC industry, driving advancements in cooling technology and contributing to a more comfortable and energy-efficient built environment. Their dedication to innovation, quality, and sustainability ensures that these essential systems continue to evolve, meeting the diverse and evolving needs of our society. Related PRODUCTS

Copyright © 2025 Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy