Suppliers of Blast Freezers and Their Temperature Specifications for Optimal Performance

Understanding Blast Freezer Temperature and Suppliers A Key Component in Food Preservation

In today's fast-paced world, the need for effective food preservation has never been more crucial. With advancements in technology and an increasing demand for high-quality food products, blast freezers have emerged as a vital tool in the food processing and storage industries. This article will explore the significance of blast freezer temperature management and the role of suppliers in providing high-quality blast freezing solutions.

What is a Blast Freezer?

A blast freezer is an industrial refrigeration unit designed to freeze products quickly and efficiently. Unlike traditional freezers that might take hours to freeze food, a blast freezer can lower the temperature of food items to sub-zero levels in a matter of minutes. This rapid freezing process is essential for preserving the texture, flavor, and nutritional value of food, especially when dealing with perishable items such as seafood, meat, fruits, and vegetables.

Importance of Temperature Control

The effectiveness of a blast freezer is largely determined by its ability to maintain consistent and optimal temperatures throughout the freezing process. Typically, blast freezers operate at temperatures ranging from -18°C to -40°C (-0.4°F to -40°F). This rapid drop in temperature helps to minimize the size of ice crystals formed within the food, a critical factor that affects both the quality and integrity of the final product. Larger ice crystals can lead to cellular damage, resulting in a loss of moisture and texture upon thawing.

Moreover, maintaining the right temperature is crucial for food safety. Bacteria thrive at certain temperatures, and the faster food can be frozen, the less time bacteria have to grow. Thus, effective temperature control not only preserves food quality but also ensures that food is safe for consumption.

Choosing the Right Supplier

When it comes to selecting a blast freezer, choosing the right supplier is paramount. Not all suppliers offer the same quality of equipment or customer service. Here are some factors to consider when evaluating potential suppliers

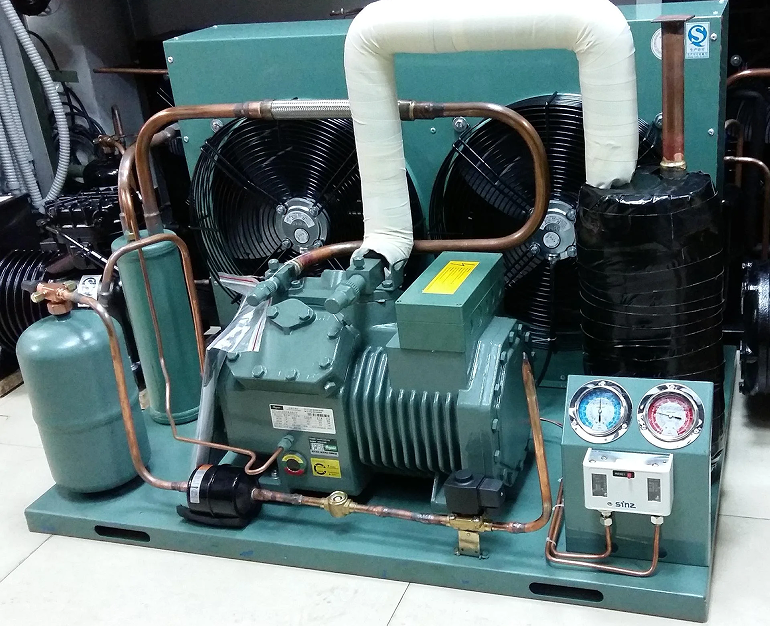

blast freezer temperature suppliers

1. Experience and Expertise A supplier with extensive experience in the blast freezing industry can provide valuable insights and recommendations. Look for suppliers that have a proven track record and extensive knowledge of refrigeration technology.

2. Quality of Equipment Ensure that the blast freezers offered by the supplier meet industry standards for quality and efficiency. Inquire about the cooling technology used, the range of temperatures offered, and the energy efficiency of their units.

3. Customization Options Different businesses have unique needs. A reputable supplier should offer customization options to tailor equipment to specific business requirements, whether it be size, capacity, or special features.

4. Support and Maintenance Successful operation of a blast freezer often depends on proper maintenance. A good supplier should provide ongoing support and maintenance services to ensure equipment operates optimally over time.

5. Customer Reviews and References Research customer testimonials and seek out references from other businesses that have purchased from the supplier. Positive reviews can provide assurance of the vendor’s reliability and quality of service.

Conclusion

The role of blast freezers in the food supply chain cannot be overstated. They are essential for preserving the quality, safety, and nutritional value of food products. Selecting the right blast freezer, along with a reliable supplier, is crucial for businesses in the food industry. Effective temperature management not only ensures the longevity of food items but also enhances consumer satisfaction by delivering high-quality products. As the industry continues to evolve, the reliance on advanced freezing technology will likely increase, making the choice of suppliers and equipment an ongoing priority for food processors and distributors alike.

In summary, as the demand for quality food products grows and food safety concerns remain at the forefront, businesses must invest in reliable blast freezing technology and choose suppliers thoughtfully. With the right equipment and partnerships, food businesses can enhance their offerings and ensure a longer shelf life for their products, ultimately benefiting consumers and the industry as a whole.