china industrial chiller specifications

Understanding China Industrial Chiller Specifications

In the realm of industrial cooling solutions, chillers play a pivotal role in maintaining optimal temperature control for various applications. China, as one of the leading manufacturers of chillers, offers a wide array of specifications to cater to diverse industry needs. Understanding these specifications is crucial for selecting the right chiller for your operation.

Firstly, industrial chillers are categorized primarily based on their cooling capacities, which can range from a few tons to several hundred tons. This capacity is a key specification, as it determines the chiller's ability to handle the thermal load of industrial processes such as plastics, pharmaceuticals, and food processing. Typically, the cooling capacity is measured in tons, where one ton is equivalent to the ability to remove 12,000 BTUs of heat per hour.

Another vital specification is the type of refrigerant used. In China, chillers often utilize environmentally friendly refrigerants like R410A or R134A, in compliance with global standards for reducing ozone depletion potential. This shift towards eco-friendly refrigerants is vital not only for regulatory compliance but also for minimizing the environmental impact of industrial operations.

Chiller efficiency is another critical parameter, usually represented by the coefficient of performance (COP) or energy efficiency ratio (EER). These ratings indicate how effectively a chiller operates under specific conditions; a higher rating signifies better energy efficiency. Chinese manufacturers are increasingly focusing on improving the efficiency of their chillers, driven by the need for sustainable energy consumption.

china industrial chiller specifications

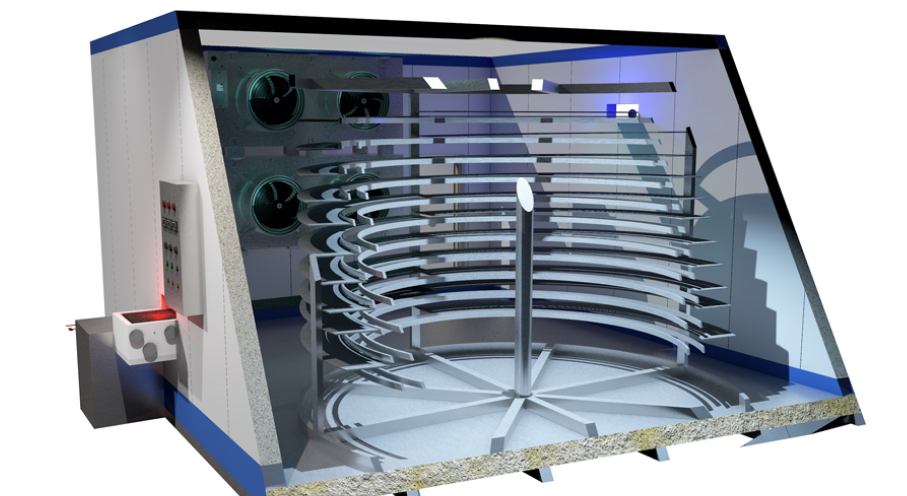

The type of chiller also matters; there are air-cooled and water-cooled chillers. Air-cooled chillers are typically easier to install and require less maintenance but may be less efficient than water-cooled models, which can offer better performance in larger systems. The choice between the two often depends on the specific requirements of the facility, including space availability, installation complexity, and cooling needs.

Furthermore, operational features such as noise levels, control systems, and ease of maintenance are important specifications to consider. Many modern chillers come equipped with advanced control systems that allow for remote monitoring and adjustments, enhancing both operational efficiency and user convenience. Noise levels, particularly in urban settings, are also a consideration, as quieter units can reduce disruptions in the work environment.

Lastly, it is essential to evaluate the build quality and safety features of the chiller. High-quality materials and robust safety mechanisms ensure longevity and safe operation, which is crucial for industrial applications.

In conclusion, selecting an industrial chiller from China involves an in-depth understanding of various specifications such as cooling capacity, refrigerant type, energy efficiency, and operational features. Armed with this knowledge, businesses can make informed decisions that enhance productivity and align with sustainability goals.