Cold Storage Panel Providers for Efficient Temperature Control Solutions

Choosing the Right Cold Storage Panels Supplier for Your Business

When it comes to maintaining the integrity of temperature-sensitive goods, the importance of choosing the right cold storage panels supplier cannot be overstated. Cold storage panels are fundamental components for facilities like warehouses, manufacturing plants, and food distribution centers, where temperature control is crucial for preserving products, ensuring safety, and maintaining quality. With numerous suppliers available in the market, making the right choice can significantly influence your operation's efficiency and reliability.

Understanding Cold Storage Panels

Cold storage panels, often referred to as insulated panels, are vital for creating temperature-controlled environments. These panels are typically made from materials such as polyurethane or polystyrene, which provide excellent insulation properties. They are designed to minimize energy loss, thus maintaining the desired internal temperature while reducing overall energy costs. The right choice of panels not only ensures that products are stored safely but also enhances the energy efficiency of your facility.

Key Factors to Consider

1. Quality of Materials The first thing to consider when selecting a cold storage panels supplier is the quality of their materials. High-quality insulation panels will have a significant impact on the performance of your cold storage facility. Ensure the supplier uses materials that comply with industry standards, are durable, and suitable for the specific temperature ranges you need.

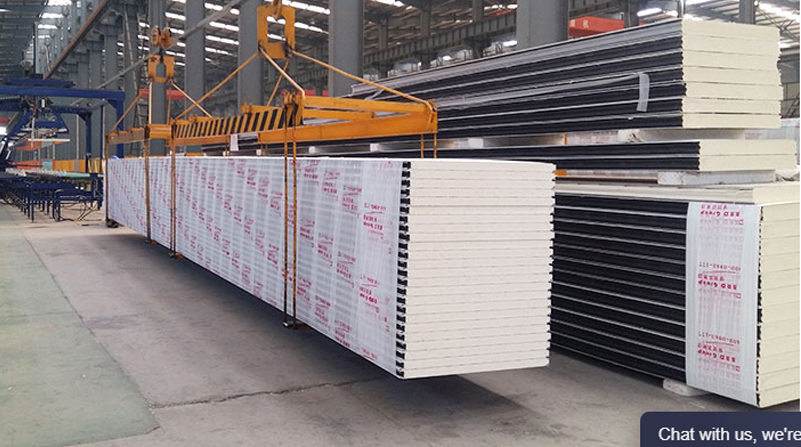

cold storage panels supplier

2. Customization Options Every business has unique requirements. Therefore, working with a supplier who can offer customizable solutions is crucial. Customization might include different thicknesses, sizes, and finishes that align with your specific operational needs. A one-size-fits-all approach may not be optimal for your setup.

3. Experience and Reputation It’s essential to choose a supplier with a proven track record and a strong reputation in the industry. Look for companies that have extensive experience in providing cold storage solutions and have positive testimonials from previous clients. An established supplier is more likely to have the expertise needed to meet your demands effectively.

4. Technical Support and After-sales Service A reliable cold storage panels supplier should offer excellent technical support. This includes assistance with installation and maintenance of the panels. Furthermore, after-sales service is crucial for addressing any issues that may arise post-installation. Suppliers that provide ongoing support can help you maximize the lifespan and efficiency of your cold storage facility.

5. Cost-effectiveness While it is essential to find a balance between quality and price, opting for the cheapest option may lead to higher costs in the long run due to poor insulation, increased energy consumption, and frequent repairs. Evaluate the overall value offered by the supplier, considering quality, warranty, and service, rather than just the initial cost.

Conclusion

In conclusion, choosing the right cold storage panels supplier is a decision that can significantly impact your operational efficiency and product safety. By considering factors such as material quality, customization options, supplier reputation, technical support, and cost-effectiveness, you’ll be better equipped to make an informed decision. Remember, investing time in selecting a reliable supplier can lead to increased productivity, decreased energy costs, and enhanced safety for your temperature-sensitive goods. As the demand for effective cold storage continues to rise, ensuring you partner with the right supplier will position your business for success in this competitive landscape.