Recommended Sizes for Cold Storage Rooms in Manufacturing Facilities

Understanding Cold Storage Room Sizes in Factories

In the fast-paced world of food production and distribution, cold storage rooms play a crucial role in ensuring the safety, freshness, and quality of perishable goods. The design and size of these rooms are paramount, as they must accommodate varying types of products, seasonal demands, and specific industry regulations. This article delves into the significance of cold storage room sizes in factories, exploring optimal dimensions, best practices, and their impact on the supply chain.

Importance of Cold Storage Rooms

Cold storage facilities are designed to store temperature-sensitive goods such as fruits, vegetables, dairy products, meat, and pharmaceuticals. Maintaining appropriate temperatures is essential to prolong shelf life, prevent spoilage, and adhere to food safety regulations. A well-designed cold storage room not only preserves products but also minimizes waste and maximizes profitability for manufacturers and distributors.

Determining Cold Storage Room Sizes

When determining the size of a cold storage room, several factors must be taken into account

1. Product Type and Volume Different products have different storage requirements. For instance, a facility that specializes in fresh produce might need larger, open space to accommodate bulkier items, while a meat processing factory may require smaller, more organized cold storage to optimize accessibility and hygiene.

2. Temperature Zones Some products may require specific temperature zones within the same facility. For example, dairy products need to be stored at temperatures around 34-38°F (1-3°C), while frozen goods must be kept at 0°F (-18°C) or lower. Therefore, multi-zoned cold storage solutions may necessitate more complex planning in terms of size and layout.

3. Future Growth Businesses need to anticipate not only current needs but also future expansions. As market demand fluctuates, the ability to scale storage capacity can be crucial. A factory may choose to build a slightly larger facility initially or design it with the possibility of adding more storage capacity in the future.

4. Operational Workflow The efficiency of operations within the cold storage room affects overall productivity. Sufficient space allows for smooth workflows, reducing bottlenecks during the receiving, storing, and shipping processes. Strategic planning regarding aisle widths and shelving configurations also contributes to optimizing space.

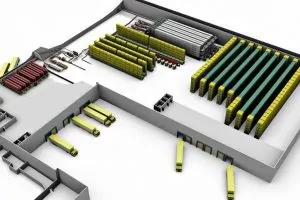

cold storage room sizes factory

Best Practices in Designing Cold Storage Rooms

To ensure cold storage rooms are efficient and effective, consider the following best practices

1. Temperature Control Systems Invest in high-quality refrigeration systems that can maintain consistent temperatures. Regular maintenance is essential to ensure these systems function optimally and do not compromise product integrity.

2. Insulation Quality Quality insulation reduces energy costs and helps maintain the required temperatures. Insulated walls, floors, and ceilings are critical, especially in larger facilities.

3. Layout Flexibility Cold storage room layouts should be designed for flexibility. Modular shelving and adjustable racking systems allow for easy reconfiguration as storage needs change.

4. Monitoring Systems Implement automated monitoring systems to keep track of temperature and humidity levels in real time. This can prevent costly spoilage and ensure compliance with health regulations.

5. Compliance and Safety Ensure that the cold storage area complies with local and international regulations concerning food safety and handling. This includes proper signage, employee training, and regular inspections.

Conclusion

Cold storage rooms are an integral component of factory operations, especially in industries dealing with perishable goods. The size and design of these facilities must reflect the specific needs of the products being stored, future growth potential, and operational efficiencies. By prioritizing best practices in cold storage design, factories can enhance their productivity, reduce waste, and ultimately ensure the safety and quality of their products. As the demand for fresh and safe food continues to rise, investing in appropriate cold storage solutions will remain vital for any industry dependent on temperature-controlled logistics.