commercial ice machine parts manufacturers

The Importance of Commercial Ice Machine Parts Manufacturers

In the fast-paced world of food and beverage service, commercial ice machines play a critical role in ensuring that establishments can keep their drinks cold, preserve food, and maintain an inviting atmosphere. These machines are essential in restaurants, bars, hotels, and grocery stores, relying heavily on high-quality parts to function optimally. Commercial ice machine parts manufacturers form the backbone of this industry, supplying essential components that directly affect the efficiency, reliability, and performance of these machines.

Understanding Commercial Ice Machines

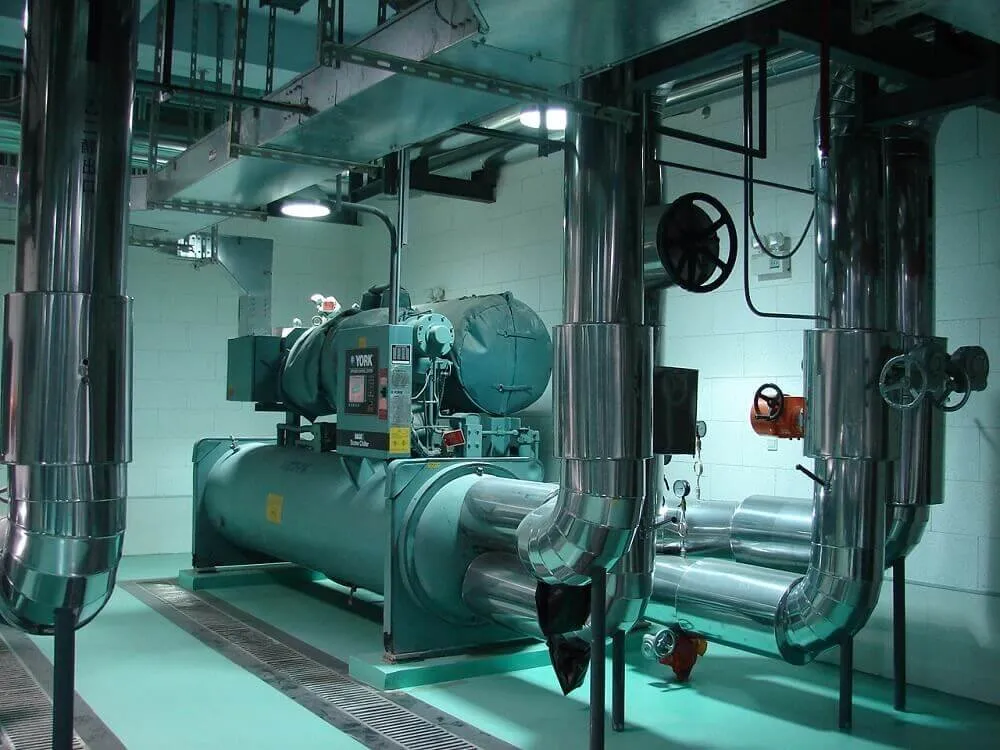

Commercial ice machines produce a variety of ice types, from cubed to nugget to flake ice, catering to different needs across various sectors. Behind this versatility is a complex network of components, including compressors, evaporators, water pumps, and various sensors. Each part requires meticulous manufacturing processes, often utilizing durable materials that can withstand the demands of commercial environments, where machines must operate continuously and efficiently.

The Role of Manufacturers

Commercial ice machine parts manufacturers focus on designing and producing the components crucial for ice machine function. These manufacturers must adhere to strict industry standards and regulations to ensure their products are safe and efficient. Quality control is essential in the manufacturing process, as any defective part can lead to machine breakdowns, resulting in costly downtime and customer dissatisfaction.

Manufacturers in this field are not just responsible for creating parts; they also engage in extensive research and development. They stay on the cutting edge of technology, developing newer, more energy-efficient components that help businesses save on operational costs while maintaining high performance. Innovations may include improved thermal conductivity in evaporators or more reliable sensors that ensure optimal freezing temperatures.

Supply Chain Dynamics

commercial ice machine parts manufacturers

The relationship between commercial ice machine manufacturers and parts suppliers is critical

. Manufacturers must ensure a consistent supply chain for raw materials, as well as a steady distribution network for finished components. This interdependence fosters a collaborative environment where manufacturers can rely on suppliers for timely deliveries, ultimately impacting the manufacturing timeline and adherence to customer demand.Additionally, global supply chain disruptions have highlighted the importance of local manufacturing sources. Companies that produce their components regionally can often react more swiftly to shortages or shifts in the market, providing a level of agility in operations that is critical in today’s economic climate.

Sustainability Practices

With the growing focus on sustainability, many commercial ice machine parts manufacturers have begun adopting environmentally friendly practices. This includes utilizing recycled materials in the production of components, implementing energy-efficient manufacturing processes, and reducing waste. By prioritizing sustainability, these manufacturers not only meet consumer demand for eco-conscious products but also contribute to the overall reduction of their carbon footprint.

Customer Support and Aftermarket Services

Another important aspect of commercial ice machine parts manufacturers is their commitment to customer support. Beyond just selling components, they often provide extensive after-sales services, including installation guidance, troubleshooting support, and maintenance recommendations. This ongoing relationship is vital for ensuring that commercial ice machines operate smoothly over their lifespan, minimizing downtime and repair costs for customers.

Conclusion

In summary, commercial ice machine parts manufacturers play a crucial role in the food and beverage industry. As demand for high-performance ice machines continues to grow, so does the need for reliable and innovative parts. These manufacturers must balance quality, efficiency, and sustainability while maintaining strong relationships within the supply chain and with their customers. The future of ice machines will depend significantly on the capabilities and advancements of these manufacturers, ensuring that businesses can continue to provide high-quality service in an increasingly competitive marketplace. As technology evolves, the capacity for manufacturers to innovate will shape the functionality and sustainability of commercial ice machines for years to come.