custom 404a ice machine pressures

Understanding the Pressures in Ice Machines A Deep Dive into Custom 404A Systems

Ice machines are essential appliances in various settings, from restaurants to bars and even healthcare facilities. They are indispensable for food preservation, beverage service, and medical applications. Among the various refrigerants used in these machines, R-404A has garnered significant attention due to its effectiveness and efficiency. However, understanding the pressure dynamics within these systems, particularly custom 404A ice machines, is crucial for optimal performance, safety, and longevity.

The Science of Refrigeration

The basic principle of refrigeration involves the transfer of heat from one area to another using a refrigerant. In the case of an ice machine, this process ensures that water is transformed into ice efficiently. R-404A is a hydrofluorocarbon (HFC) blend that has been widely used in commercial refrigeration applications. It operates under specific pressure and temperature relationships that are vital for proper functionality.

Pressure in Ice Machines

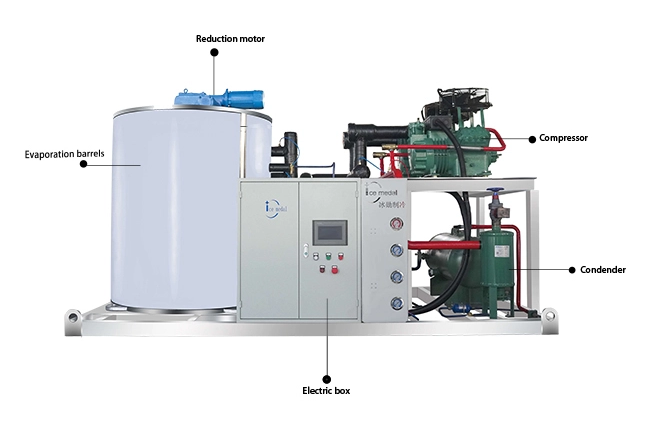

In any refrigeration cycle, pressure plays a significant role. An ice machine using R-404A typically operates at varying pressures in different stages of the cycle. The system comprises a compressor, condenser, expansion valve, and evaporator.

1. Compressor The cycle begins here, where the refrigerant gas is compressed. This action increases its temperature and pressure. For R-404A ice machines, the typical discharge pressure ranges from 250 to 300 psi, depending on the ambient temperature and specific machine design.

2. Condenser The high-pressure refrigerant gas then flows to the condenser, where it releases heat to the environment and condenses into a liquid. The pressure in the condenser usually hovers around 200 to 250 psi. The effectiveness of this stage is essential, as inadequate heat release can cause the machine to overheat, impacting ice production rates.

3. Expansion Valve After leaving the condenser, the refrigerant enters the expansion valve. Here, the pressure drops significantly, typically to around 25 to 50 psi. This pressure drop allows the refrigerant to enter the evaporator as a low-pressure liquid, ready to absorb heat and evaporate.

custom 404a ice machine pressures

4. Evaporator In the evaporator, the refrigerant absorbs heat from the water, causing it to freeze into ice. The pressure in this stage is generally around 10 to 15 psi. The efficiency of this process directly affects the ice production rate and overall energy consumption of the machine.

Importance of Monitoring Pressures

Maintaining the correct pressure levels in custom 404A ice machines is vital for several reasons

- Efficiency Deviations from the optimal pressure range can lead to inefficient ice production, increased energy consumption, and higher operational costs.

- Longevity Incorrect pressure levels can place undue stress on the components of the ice machine, leading to premature wear and potential breakdowns.

- Safety Over-pressurization can be hazardous. Manufacturers typically include safety features and pressure relief valves, but regular maintenance and pressure monitoring are essential to prevent dangerous situations.

Conclusion

In summary, the pressures within custom 404A ice machines are foundational to their operation. Understanding the refrigeration cycle, from compression to evaporation, allows operators to enhance performance, ensure safety, and extend the lifespan of the equipment. As the industry continues to evolve with greater environmental awareness, maintaining optimal pressure levels while exploring sustainable refrigerants will be crucial. Thus, investing time in understanding and monitoring the pressures in ice machines not only pays off in terms of efficiency and safety but also contributes to a more sustainable future in refrigeration technology.