Jun . 16, 2024 18:44

Back to list

Ice cream factory flaker.

The Ice Machine Flaker Factory A Revolution in Cold Storage

In the heart of a bustling industrial district, surrounded by towering steel structures and the hum of machinery, lies a factory that stands out for its unique purpose. This is no ordinary manufacturing plant; it is the home of the ice machine flaker factory, a revolutionary facility that produces flaked ice on an industrial scale.

Flaked ice, with its uniform size and shape, has become an essential component in a wide range of industries. From food processing to pharmaceuticals, from seafood storage to construction, flaked ice is used to maintain the optimal temperature and protect sensitive products from damage. The demand for high-quality flaked ice has grown exponentially in recent years, leading to the establishment of specialized factories like this one.

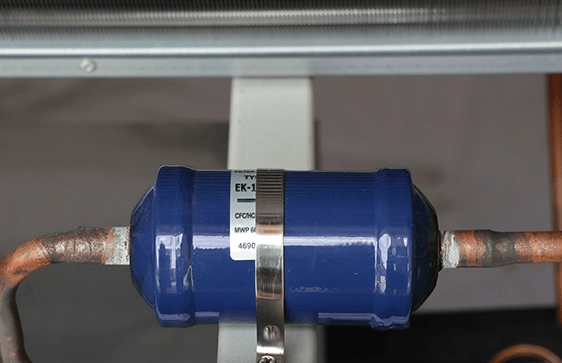

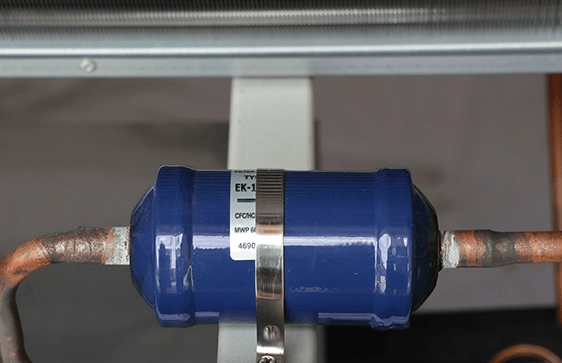

The ice machine flaker factory is a state-of-the-art facility equipped with the latest technology. The production line is designed to maximize efficiency and output, with advanced machinery that can produce thousands of pounds of flaked ice per hour. The ice is made from pure, filtered water that is passed through a series of precision filters to remove impurities. The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape

The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape ice machine flaker factory.

One of the key advantages of the ice machine flaker factory is its environmental sustainability. Unlike traditional ice makers that rely on Freon or other refrigerants, this factory uses a closed-loop system that recycles the water used in the production process. This not only reduces waste but also helps to minimize the factory's carbon footprint.

The factory operates 24/7, with a team of skilled workers monitoring the equipment and ensuring that production runs smoothly. The high level of automation means that the factory can operate with minimal human intervention, reducing costs and increasing efficiency.

As the demand for flaked ice continues to grow, the ice machine flaker factory is well positioned to meet the challenges of the future. With its advanced technology, sustainable practices, and commitment to quality, this factory is at the forefront of the cold storage industry, setting new standards for efficiency, quality, and environmental responsibility.

ice machine flaker factory.

One of the key advantages of the ice machine flaker factory is its environmental sustainability. Unlike traditional ice makers that rely on Freon or other refrigerants, this factory uses a closed-loop system that recycles the water used in the production process. This not only reduces waste but also helps to minimize the factory's carbon footprint.

The factory operates 24/7, with a team of skilled workers monitoring the equipment and ensuring that production runs smoothly. The high level of automation means that the factory can operate with minimal human intervention, reducing costs and increasing efficiency.

As the demand for flaked ice continues to grow, the ice machine flaker factory is well positioned to meet the challenges of the future. With its advanced technology, sustainable practices, and commitment to quality, this factory is at the forefront of the cold storage industry, setting new standards for efficiency, quality, and environmental responsibility.

The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape

The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape The water is then frozen using state-of-the-art evaporators before being flaked into the desired size and shape ice machine flaker factory.

One of the key advantages of the ice machine flaker factory is its environmental sustainability. Unlike traditional ice makers that rely on Freon or other refrigerants, this factory uses a closed-loop system that recycles the water used in the production process. This not only reduces waste but also helps to minimize the factory's carbon footprint.

The factory operates 24/7, with a team of skilled workers monitoring the equipment and ensuring that production runs smoothly. The high level of automation means that the factory can operate with minimal human intervention, reducing costs and increasing efficiency.

As the demand for flaked ice continues to grow, the ice machine flaker factory is well positioned to meet the challenges of the future. With its advanced technology, sustainable practices, and commitment to quality, this factory is at the forefront of the cold storage industry, setting new standards for efficiency, quality, and environmental responsibility.

ice machine flaker factory.

One of the key advantages of the ice machine flaker factory is its environmental sustainability. Unlike traditional ice makers that rely on Freon or other refrigerants, this factory uses a closed-loop system that recycles the water used in the production process. This not only reduces waste but also helps to minimize the factory's carbon footprint.

The factory operates 24/7, with a team of skilled workers monitoring the equipment and ensuring that production runs smoothly. The high level of automation means that the factory can operate with minimal human intervention, reducing costs and increasing efficiency.

As the demand for flaked ice continues to grow, the ice machine flaker factory is well positioned to meet the challenges of the future. With its advanced technology, sustainable practices, and commitment to quality, this factory is at the forefront of the cold storage industry, setting new standards for efficiency, quality, and environmental responsibility. Related PRODUCTS

Copyright © 2025 Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy