Top Manufacturers of Industrial Cold Storage Solutions for Optimal Food Preservation

The Role of Industrial Cold Storage Room Manufacturers in the Supply Chain

In today's global economy, the demand for efficient and reliable cold storage solutions is higher than ever. Industrial cold storage rooms have become an indispensable component of various sectors, including food, pharmaceuticals, and chemicals. Manufacturers specializing in cold storage solutions play a vital role in ensuring that products are preserved under optimal conditions, thereby reducing waste and improving safety. This article explores the significance of industrial cold storage room manufacturers and what makes them essential to the modern supply chain.

The Importance of Cold Storage

Cold storage facilities are designed to maintain low temperatures, which inhibit the growth of bacteria and preserve the quality of perishable goods. In the food industry, these rooms are crucial for storing meat, dairy products, fruits, and vegetables. The pharmaceutical industry also relies heavily on cold storage for vaccines and medications that require specific temperature conditions to remain effective. By leveraging advanced cooling technologies, industrial cold storage room manufacturers provide crucial support to businesses in maintaining product integrity and complying with regulatory standards.

Key Features of Industrial Cold Storage Rooms

Manufacturers of industrial cold storage rooms typically focus on several key features

1. Temperature Control Systems At the heart of cold storage rooms are sophisticated temperature control systems that can efficiently maintain specific temperature ranges. Many manufacturers employ advanced digital thermostats and monitoring systems to ensure that temperatures are stable and within the desired range.

2. Insulation Materials The effectiveness of a cold storage room is largely dependent on its insulation. Manufacturers utilize high-quality insulation materials that offer minimal thermal conductivity, ensuring that the internal environment remains stable despite external temperature fluctuations.

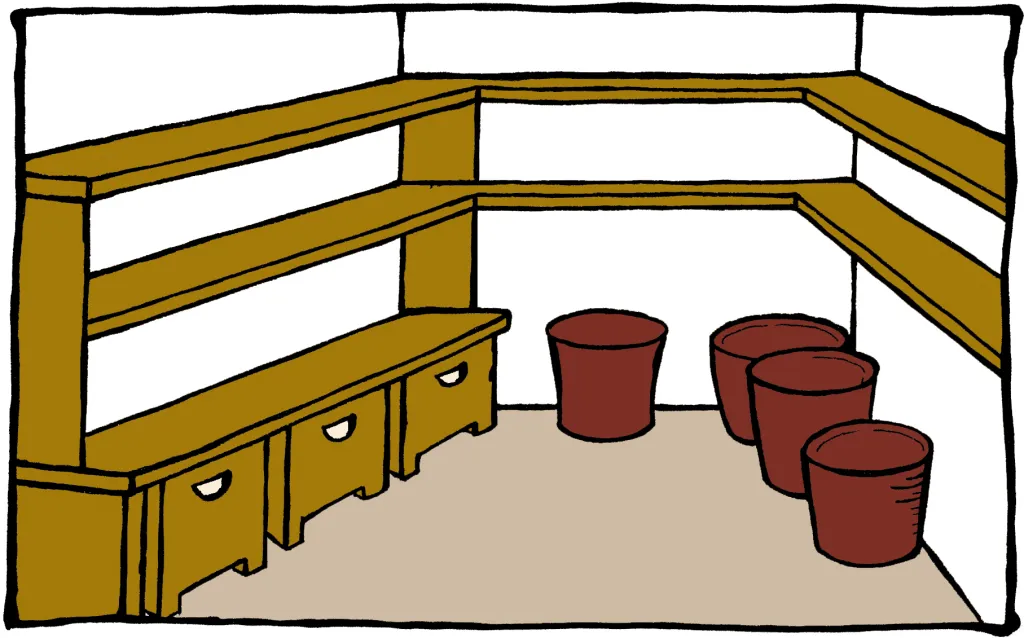

3. Customizability Every business has unique needs, which is why many manufacturers offer customizable solutions. From the size and layout of the cold storage room to the type of shelving and racking systems, manufacturers work with clients to design facilities that meet their specific requirements.

4. Energy Efficiency As energy costs continue to rise, manufacturers are increasingly focusing on energy-efficient solutions. By using advanced refrigeration technology and energy-saving systems, these manufacturers help businesses reduce their overall operational costs while also minimizing their carbon footprint.

industrial cold storage room manufacturers

5. Hygienic Design In industries such as food and pharmaceuticals, cleanliness is paramount. Manufacturers incorporate hygienic design principles into their cold storage solutions, using materials that are easy to clean and resistant to bacteria and mold.

The Manufacturing Process

The process of creating industrial cold storage rooms typically involves several stages, from initial design and engineering to the final installation. Manufacturers often engage in close collaborations with clients to understand their specific needs and constraints. This helps ensure that the final product not only meets industry standards but also aligns with the client’s operational goals.

The manufacturing phase involves sourcing high-quality materials, employing skilled labor, and utilizing advanced machinery to assemble the components. Quality control is essential throughout the process to ensure that the cold storage room operates effectively and adheres to safety regulations.

Challenges in the Cold Storage Industry

Despite the advantages provided by industrial cold storage room manufacturers, the industry is not without its challenges. Rising energy costs, stringent regulatory requirements, and the ongoing impacts of climate change have created an uncertain environment for businesses. Manufacturers must continuously innovate to overcome these challenges, ensuring their products remain competitive and effective.

Moreover, as the demand for cold storage grows, manufacturers face pressure to scale their operations. This means investing in new technologies and expanding production capacity to meet impending market needs.

Conclusion

The role of industrial cold storage room manufacturers can’t be understated. They are essential players in the supply chain, providing businesses with the means to safely store and protect their products. By focusing on quality, efficiency, and innovation, these manufacturers help mitigate waste, ensure compliance, and improve overall product quality. As industries continue to evolve, the importance of reliable cold storage solutions is set to grow, making the role of manufacturers even more critical in the years to come. Their contributions not only enhance operational efficiency but also ensure that consumers receive safe and high-quality products.