industrial tube ice machine manufacturer

Industrial Tube Ice Machine Manufacturer Revolutionizing Ice Production

In a world where the demand for ice is ever-increasing—from restaurants to hospitals, and from fishing fleets to industrial applications—the rise of industrial tube ice machine manufacturers is shaping how ice is produced and distributed. These manufacturers are at the forefront of innovation, providing efficient solutions that meet the diverse needs of various industries.

Understanding Tube Ice

Before diving into the manufacturers, it is essential to understand what tube ice is. Tube ice is characterized by its hollow cylindrical shape, which allows for quicker cooling and a longer duration of preservation compared to traditional ice cubes. The unique design facilitates better airflow and enables it to last longer in storage, making it highly sought after in various sectors, including food processing, beverage cooling, and even medical applications.

The Role of Manufacturers

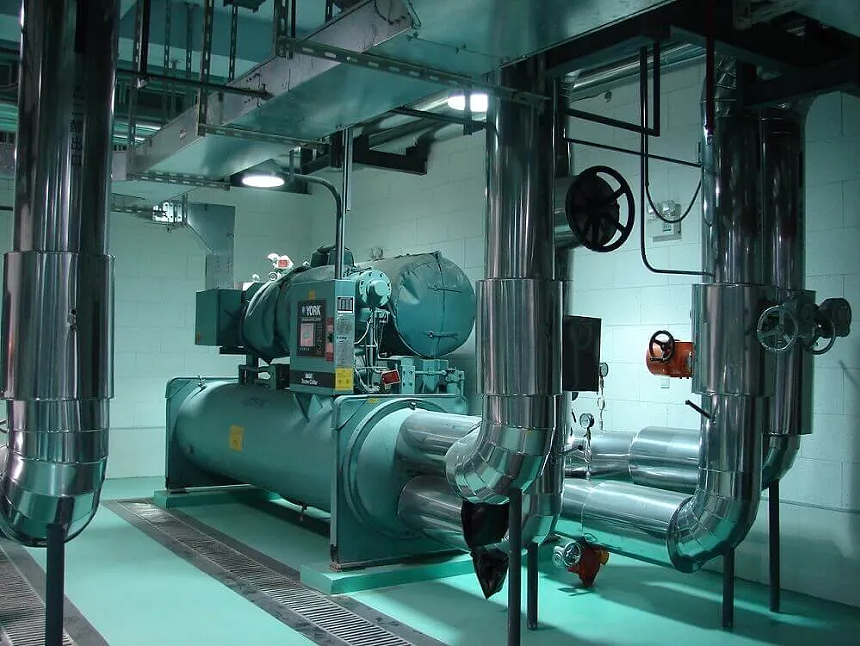

The role of industrial tube ice machine manufacturers extends beyond mere production. They play a critical role in research and development, ensuring that their machines are equipped with the latest technology to enhance efficiency and reduce energy consumption. Leading manufacturers invest heavily in R&D to develop machines that can produce high volumes of tube ice while maintaining quality and reliability.

Additionally, manufacturers often provide customizable solutions tailored to the specific needs of their clients. This flexibility allows businesses, regardless of size, to obtain the right equipment that aligns with their operational requirements and production capacity. Whether a small seafood market or a large-scale beverage distributor, there is a solution available from industrial tube ice machine manufacturers.

Quality Standards and Compliance

Quality assurance is paramount in the manufacturing process. Reputable manufacturers adhere to stringent quality standards, ensuring their machines are fabricated using durable materials that withstand constant operation. Compliance with international standards, such as ISO certifications, indicates a manufacturer’s commitment to quality and reliability. Customers can be confident in the longevity and performance of the machines they invest in when working with certified manufacturers.

industrial tube ice machine manufacturer

Energy Efficiency and Sustainability

As global awareness regarding environmental issues grows, so does the responsibility of industrial tube ice manufacturers to produce energy-efficient machines. The trend is shifting towards sustainable practices, and leading manufacturers are adopting technologies that minimize energy consumption without compromising on ice production capacity. These advancements not only reduce the operating costs for end-users but also contribute to the global effort of lowering carbon footprints in industrial operations.

After-Sales Support and Service

The relationship between manufacturers and their clients doesn’t end with the purchase of a machine. Quality after-sales support is a vital component of the manufacturing process. Many leading manufacturers offer comprehensive service packages, including installation, maintenance, and emergency repairs. This ongoing support ensures that businesses can rely on their ice production systems without significant downtime, which is critical in an industry where ice is often a necessity for daily operations.

Innovation and Future Trends

As technology continues to evolve, so too will the industrial tube ice machine. Innovations like IoT integration, which allows for remote monitoring and operation of machines, are becoming increasingly popular. These advancements facilitate proactive maintenance and improve operational efficiencies, further solidifying the importance of partnering with a forward-thinking manufacturer.

Moreover, the continuous development in automation technologies is expected to play a significant role in the manufacturing process, optimizing production capabilities and ensuring that manufacturers can handle increased demand.

Conclusion

In conclusion, industrial tube ice machine manufacturers are pivotal in shaping the future of ice production. Their commitment to quality, innovation, and sustainability places them at the forefront of the industry. As demand for high-quality tube ice continues to soar, partnering with the right manufacturer becomes imperative for businesses looking to thrive in today’s competitive landscape. Investing in efficient machinery is not just a business decision; it’s a step towards operational excellence and sustainability in an increasingly ice-dependent world.